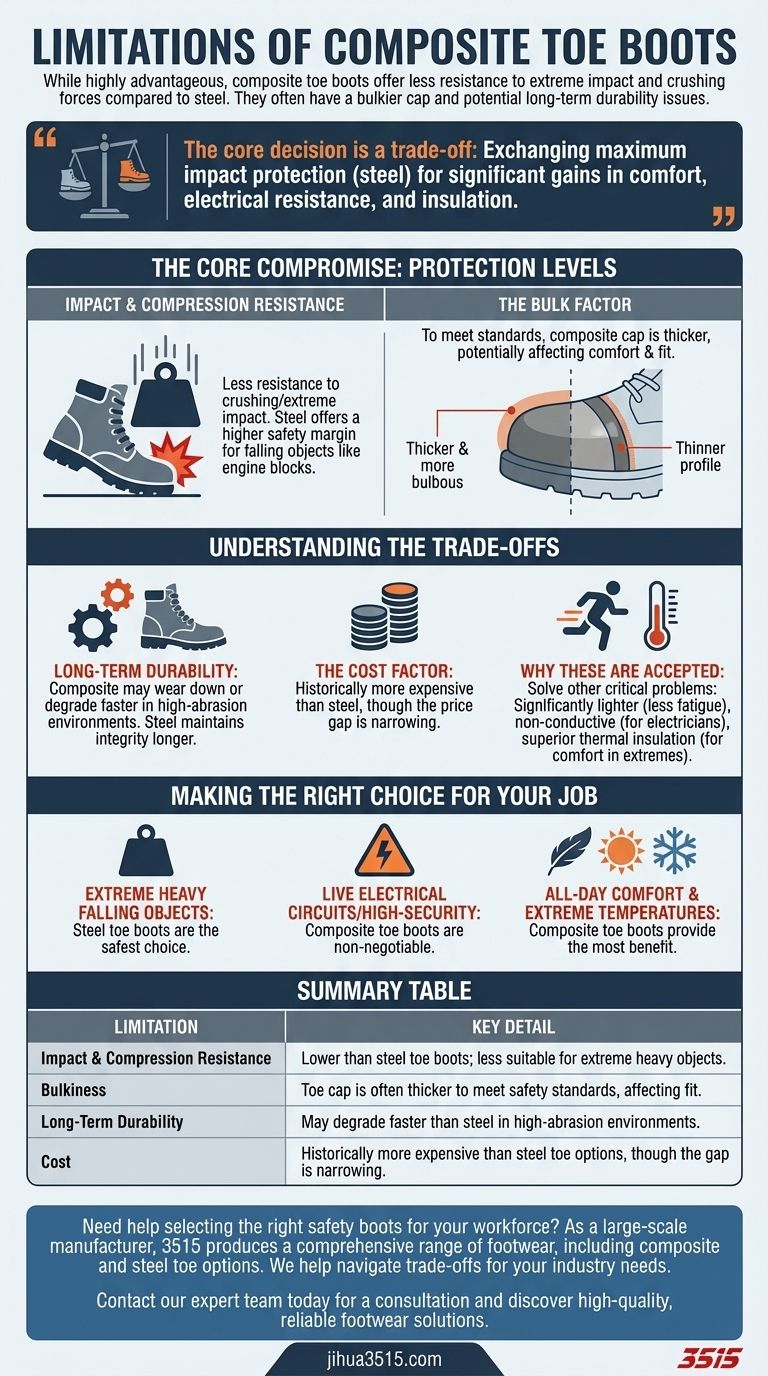

While highly advantageous in many scenarios, the primary limitations of composite toe boots are that they offer less resistance to extreme impact and crushing forces compared to steel toe boots. To meet safety standards, the protective cap is often bulkier, and the material may exhibit less long-term durability against wear and tear.

The core decision between composite and other safety toes is a trade-off. You are often exchanging the absolute maximum impact protection, found in steel, for significant gains in comfort, electrical resistance, and insulation.

The Core Compromise: Protection Levels

While all safety boots must meet specific ASTM safety standards to be sold as such, the materials they are made from dictate their ultimate failure points. Understanding these differences is key.

Impact & Compression Resistance

Composite materials, while strong, do not have the same resistance to crushing force or direct, heavy impact as solid steel. For work environments with a high risk of falling objects like engine blocks or concrete, steel provides a higher safety margin.

The Bulk Factor

To achieve the required safety rating, a composite toe cap must be thicker and more bulbous than a steel or alloy equivalent. This can make the boot feel bulkier at the front, potentially affecting comfort and fit for some individuals.

Understanding the Trade-offs

Choosing composite toe boots involves weighing their limitations against a set of powerful advantages. The "right" choice depends entirely on your work environment and daily tasks.

Long-Term Durability

Some evidence suggests that composite materials may wear down or degrade faster than a steel cap, especially in environments with high abrasion. Steel is an exceptionally durable material that maintains its integrity for years.

The Cost Factor

Historically, composite toe boots have been more expensive than their steel counterparts. While this price gap is narrowing as the technology becomes more common, it can still be a deciding factor for many buyers.

Why These Limitations are Often Accepted

The trade-offs are accepted because composite boots solve other critical problems. They are significantly lighter (up to 30% less than steel), which reduces fatigue over a long workday.

Furthermore, they do not conduct electricity, making them essential for electricians and engineers. They also provide superior thermal insulation, keeping feet more comfortable in extreme heat or cold without transferring the ambient temperature.

Making the Right Choice for Your Job

Your specific workplace hazards should always dictate your choice of personal protective equipment.

- If your primary risk is from extremely heavy falling or rolling objects: The superior impact and compression resistance of steel toe boots is your safest choice.

- If you work with live electrical circuits or in high-security areas: The non-conductive, metal-free properties of composite toe boots are non-negotiable.

- If you prioritize all-day comfort and work in extreme temperatures: The lightweight and insulating nature of composite toe boots will provide the most benefit.

Ultimately, understanding these limitations empowers you to select the precise tool your job demands.

Summary Table:

| Limitation | Key Detail |

|---|---|

| Impact & Compression Resistance | Lower than steel toe boots; less suitable for extreme heavy objects. |

| Bulkiness | Toe cap is often thicker to meet safety standards, affecting fit. |

| Long-Term Durability | May degrade faster than steel in high-abrasion environments. |

| Cost | Historically more expensive than steel toe options, though the gap is narrowing. |

Need help selecting the right safety boots for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both composite and steel toe safety footwear. We can help you navigate these trade-offs to find the perfect balance of safety, comfort, and durability for your specific industry needs.

Contact our expert team today for a consultation and discover how we can support your business with high-quality, reliable footwear solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- Why are industrial-grade safety shoes prioritized in automated PPE monitoring? Enhance Workplace Safety Today

- What does a yellow triangle symbol on safety footwear mean? A Guide to CSA Grade 2 Protection

- What is the significance of standard compliance for safety equipment within a sustainable construction safety framework? Ensuring Reliable Protection & Mitigating Risk

- What role do specialized rubber composite materials play in the material selection for fire safety shoes? Core Safety Role

- What is the function of the upper in safety shoes? Your Guide to Foot Protection & Comfort

- How do specialized burners and sample holders function in fire safety boot tests? Ensuring Standardized Performance

- Why incorporate plantar pressure in gait analysis? Enhance Design and Accuracy for Tactical & Safety Footwear

- What role do inertial sensors play in footwear-based fall detection? Advanced Kinetic Motion Analysis