At its core, the Goodyear welt construction process is a meticulous, multi-stage method for attaching a shoe's upper to its sole. The key steps involve preparing a specialized insole, stretching the upper over a form (the "last"), stitching a leather strip called a welt to both the upper and the insole, filling the resulting cavity with cork, and finally, stitching the outsole to that same welt. This indirect attachment is what defines the entire method.

The central principle of a Goodyear welt is that the outsole is not stitched directly to the upper. Instead, the welt acts as a durable intermediary, creating a robust, water-resistant, and easily repairable shoe structure.

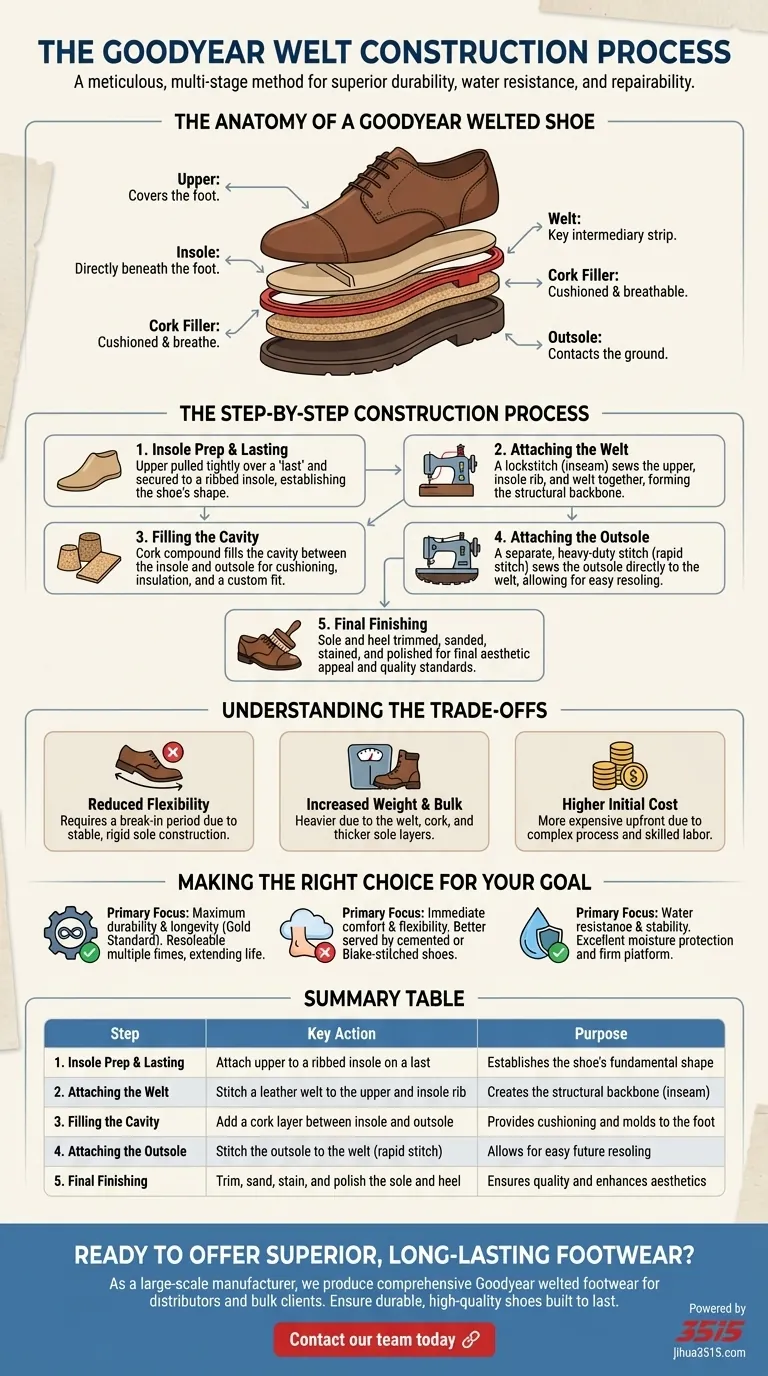

The Anatomy of a Goodyear Welted Shoe

Before examining the process, it's essential to understand the key components. This construction method fundamentally changes how these parts interact.

The Key Components

The upper is the main body of the shoe that covers your foot. The insole is the material directly beneath your foot, while the outsole is the part that contacts the ground.

The welt is the star of this method. It is a strip of material, typically leather, that runs along the perimeter of the outsole.

Finally, a cork filler is used to create a cushioned and breathable layer between the insole and the outsole.

The Step-by-Step Construction Process

Each step in the Goodyear welt process is deliberate, designed to build a shoe that is both stable and serviceable for years.

Step 1: Insole Preparation and Lasting

The process begins with the insole, which is prepared with a vertical "rib" on its underside.

The shoe's upper is then pulled tightly over a foot-shaped model called a last. It is temporarily secured to the insole's rib, giving the shoe its fundamental shape.

Step 2: Attaching the Welt

This is the defining moment. A specialized machine uses a lockstitch to sew the upper, the insole rib, and the welt together.

This first critical seam, known as the inseam, is hidden from view in the finished shoe but forms the structural backbone of the entire assembly.

Step 3: Filling the Cavity

The welt and the insole rib create a shallow cavity in the center of the shoe's bottom.

This space is filled with a layer of cork compound. The cork provides cushioning, insulation, and breathability, and over time, it will mold to the wearer's foot for a custom fit.

Step 4: Attaching the Outsole

The outsole is now placed onto the bottom of the shoe. A separate, heavy-duty stitch, called the rapid stitch, is used to sew the outsole directly to the welt.

This second seam is visible around the perimeter of the sole and is what allows a cobbler to easily remove and replace the outsole without disturbing the upper.

Step 5: Final Finishing

The final stages involve trimming the sole and heel to their final shape. Craftsmen then sand, stain, polish, and clean the shoe to meet exacting quality standards, enhancing its final aesthetic appeal.

Understanding the Trade-offs

While revered for its quality, the Goodyear welt method is not without its compromises. Acknowledging them is key to making an informed decision.

Reduced Flexibility

The multi-layer construction and dual-stitching process create a very stable but inherently rigid sole. This means Goodyear welted shoes often require a significant "break-in" period to become comfortable.

Increased Weight and Bulk

The welt itself, the cork filling, and the often thicker soles contribute to a heavier and bulkier shoe compared to more streamlined construction methods like cementing (gluing).

Higher Initial Cost

The complexity of the process, the specialized machinery, and the skilled labor required make Goodyear welted footwear significantly more expensive upfront than most other types of shoes.

Making the Right Choice for Your Goal

The decision to invest in Goodyear welted footwear depends entirely on your priorities.

- If your primary focus is maximum durability and longevity: This construction is the gold standard, as the ability to resole the shoe multiple times can extend its life for decades.

- If your primary focus is immediate, out-of-the-box comfort and flexibility: You may be better served by a cemented or Blake-stitched shoe, which is lighter and requires little to no break-in period.

- If your primary focus is water resistance and stability: The Goodyear welt provides excellent protection from moisture seeping in from below and offers a firm, supportive platform underfoot.

Ultimately, choosing a Goodyear welt is an investment in a specific philosophy of craftsmanship, longevity, and repairability.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Insole Prep & Lasting | Attach upper to a ribbed insole on a last | Establishes the shoe's fundamental shape |

| 2. Attaching the Welt | Stitch a leather welt to the upper and insole rib | Creates the structural backbone (inseam) |

| 3. Filling the Cavity | Add a cork layer between insole and outsole | Provides cushioning and molds to the foot |

| 4. Attaching the Outsole | Stitch the outsole to the welt (rapid stitch) | Allows for easy future resoling |

| 5. Final Finishing | Trim, sand, stain, and polish the sole and heel | Ensures quality and enhances aesthetics |

Ready to Offer Superior, Long-Lasting Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted and other constructed footwear for distributors, brand owners, and bulk clients. Our extensive production capabilities ensure you receive durable, high-quality shoes and boots built to last.

Contact our team today to discuss how we can meet your specific manufacturing needs and deliver exceptional value to your customers.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management