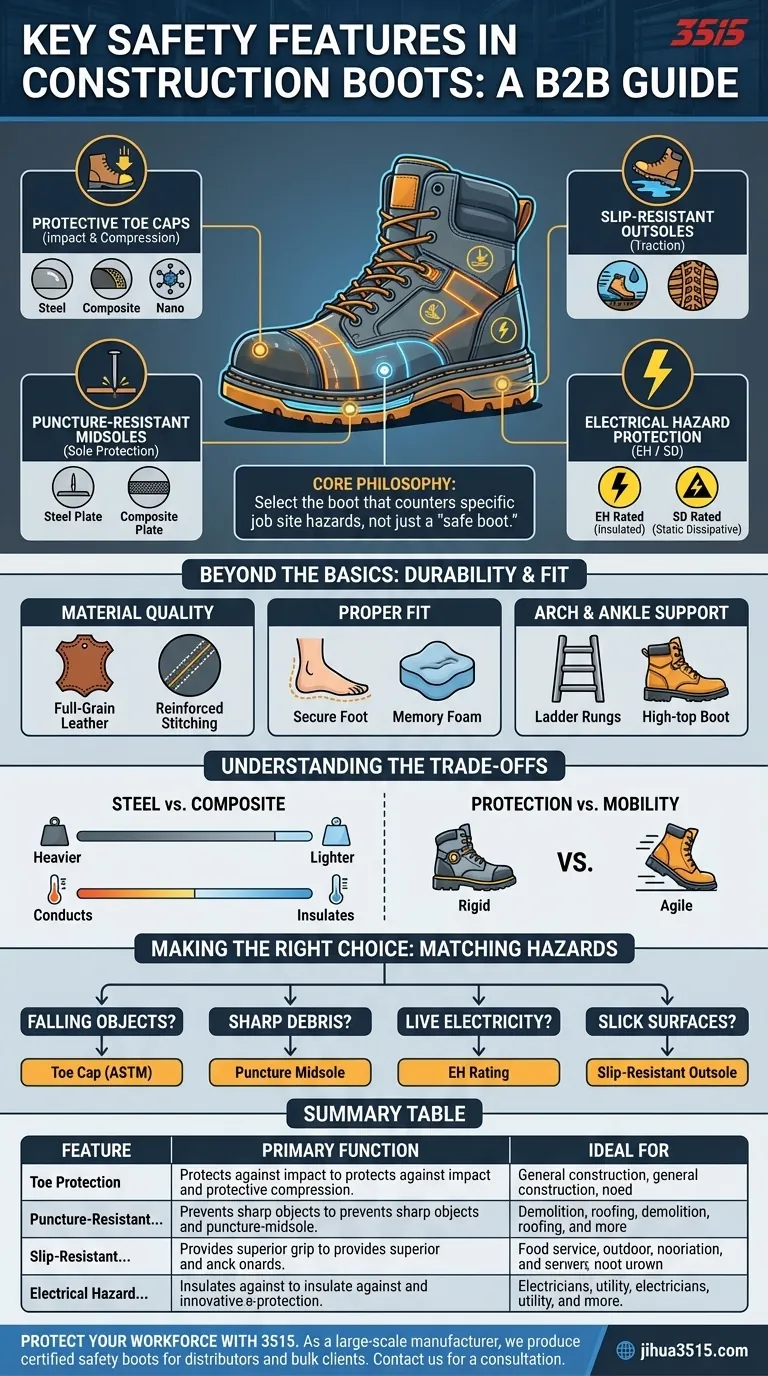

The most critical safety features in construction boots are protective toe caps, puncture-resistant midsoles, slip-resistant outsoles, and electrical hazard protection. These components work together to shield your feet from the most common and severe job site hazards, including impact from falling objects, piercing from sharp debris, and slips or electrocution.

Your goal is not simply to buy a "safe boot," but to select the right boot that directly counters the specific hazards of your daily work environment. Understanding the function of each feature is the key to making an informed and truly safe choice.

Core Protective Features Explained

The foundation of any safety boot lies in its ability to protect against direct physical threats. These are the non-negotiable features designed to prevent immediate and serious injury.

Toe Protection (Impact & Compression)

The most recognized safety feature is the protective toe cap, which guards against falling objects and compression from heavy equipment. There are three primary types: steel, composite, and nano. All must meet the same safety standards for impact and compression resistance.

Puncture Resistance (Sole Protection)

A reinforced midsole plate prevents sharp objects like nails, screws, or rebar from penetrating the bottom of the boot. This feature is absolutely essential on demolition sites, new construction frames, or any environment with scattered debris. These plates can be made of steel or flexible composite materials.

Slip Resistance (Traction)

Slips, trips, and falls are among the most frequent causes of workplace injuries. A high-quality, slip-resistant outsole is designed with specific tread patterns and rubber compounds to provide superior grip on wet, oily, or uneven surfaces.

Electrical Hazard Protection

This is a critical, specialized feature. Electrical Hazard (EH) rated boots are insulated to protect you from accidental contact with live electrical circuits. Conversely, Static Dissipative (SD) boots are designed to reduce the buildup of static electricity, which is vital in environments with flammable materials or sensitive electronics.

Beyond the Basics: Durability and Fit

A safety feature is only effective if the boot remains intact and can be worn comfortably for a full workday. High-quality construction and proper fit are secondary safety features in their own right.

Material and Construction Quality

Look for durable materials like full-grain leather and high-quality bonding between the upper boot and the outsole. Robust laces, zippers, or pull tabs are also indicators of a well-made boot that won't fail under stress.

The Importance of a Proper Fit

An ill-fitting boot can cause blisters, fatigue, and instability, turning into a distraction and a safety risk. A proper fit ensures your foot is secure, preventing internal movement that could lead to a slip or twisted ankle. Features like memory foam insoles and moisture-wicking liners add comfort that reduces fatigue.

Arch and Ankle Support

Reinforced arches provide essential support when climbing ladders, reducing foot strain. Higher boot construction offers greater ankle support, protecting against sprains and twists on uneven terrain.

Understanding the Trade-offs

Choosing the perfect boot involves balancing competing factors. Being aware of these trade-offs allows you to prioritize what matters most for your specific job.

Steel vs. Composite Materials

Steel toes offer maximum protection but are heavier and conduct heat and cold. Composite toes and puncture plates are significantly lighter, don't conduct temperature, and won't set off metal detectors, but can sometimes result in a bulkier boot profile.

Protection vs. Mobility

Heavily armored boots with maximum protective features can be rigid and heavy, potentially reducing your agility. A mechanic who needs to crouch and move frequently might prioritize a lighter, more flexible boot over one designed for a heavy demolition worker.

Generic vs. Trade-Specific Design

A "general purpose" safety boot may not be optimized for your work. A roofer needs flexibility and grip, while a concrete worker needs waterproofing and chemical resistance. Always consider boots designed with the challenges of your specific trade in mind.

Making the Right Choice for Your Work

Evaluate your daily environment to determine your non-negotiable features.

- If your primary focus is protection from falling objects: Your non-negotiable feature is an ASTM-rated steel, composite, or nano toe cap.

- If your primary focus is working on sites with sharp debris: You must have a boot with a puncture-resistant midsole plate.

- If your primary focus is working around live electricity: An Electrical Hazard (EH) rating is an absolute requirement for your safety.

- If your primary focus is navigating slick or uneven surfaces: Prioritize a boot with a certified, high-traction, slip-resistant outsole.

Ultimately, investing in the right safety boot is a direct investment in your own well-being on the job.

Summary Table:

| Key Safety Feature | Primary Function | Ideal For |

|---|---|---|

| Toe Protection (Steel/Composite) | Protects against impact and compression from falling objects. | General construction, warehousing, logistics. |

| Puncture-Resistant Midsole | Prevents sharp objects like nails from penetrating the sole. | Demolition, framing, roofing, sites with debris. |

| Slip-Resistant Outsole | Provides superior grip on wet, oily, or uneven surfaces. | Food service, plumbing, outdoor work in all weather. |

| Electrical Hazard (EH) Rating | Insulates against accidental contact with live circuits. | Electricians, utility workers, industrial settings. |

Protect your workforce with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and work shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring durability, comfort, and compliance with the highest safety standards. Let us help you equip your team with the perfect boots for their specific job hazards.

Contact 3515 today for a consultation and discover how we can meet your safety footwear needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- In which work environments are composite toe boots particularly advantageous? Essential for Electrical, Security, and Extreme Weather Jobs

- What is the primary purpose of integrating a Kevlar layer into fire safety boots? Unmatched Cut Protection Explained

- What are the main differences between pull-on and lace-up work boots? Find Your Perfect Fit for Safety & Comfort

- What safety boots are recommended for the manufacturing industry? Ensure Complete Protection & Comfort

- What are the categories of leather used in cowboy boots? A Guide to Durability & Exotic Style

- What safety features are important for electricians and HVAC technicians' work boots? Get Certified EH & Composite Toe Protection

- What essential features must every fire boot provide? Ensure Total Firefighter Safety & Performance

- What is the purpose of a boot's outsole and what variations exist? Choose the Right Sole for Your Activity