The most critical features to consider when selecting work boots are safety protection, support, traction, and durability, all of which must be tailored to your specific work environment. The right boot isn't just about a single feature like a steel toe; it's a complete system designed to mitigate the unique risks and demands of your job, from electrical hazards to slippery surfaces.

Choosing the right work boot isn't about finding the "best" boot overall, but about finding the one that is a direct reflection of your daily tasks and job site conditions. The environment dictates the necessary features.

The Foundation: Matching the Boot to Your Job

Before analyzing individual features, you must first assess your work environment. The specific demands of your job will determine which features are non-negotiable and which are secondary.

A welder requires boots that protect against sparks and high heat, making flame-resistant soles and durable leather uppers essential. In contrast, a mechanic working on slick concrete floors needs maximum slip-resistance and a lightweight, comfortable design to reduce fatigue.

A surveyor navigating rough, uneven terrain needs boots with deep-tread traction, waterproofing for the elements, and robust ankle support to prevent injury. Each role has a unique risk profile that your footwear must address.

Deconstructing the Key Features

Once you understand your environment, you can evaluate the specific components of a work boot. These features work together to provide comprehensive protection and performance.

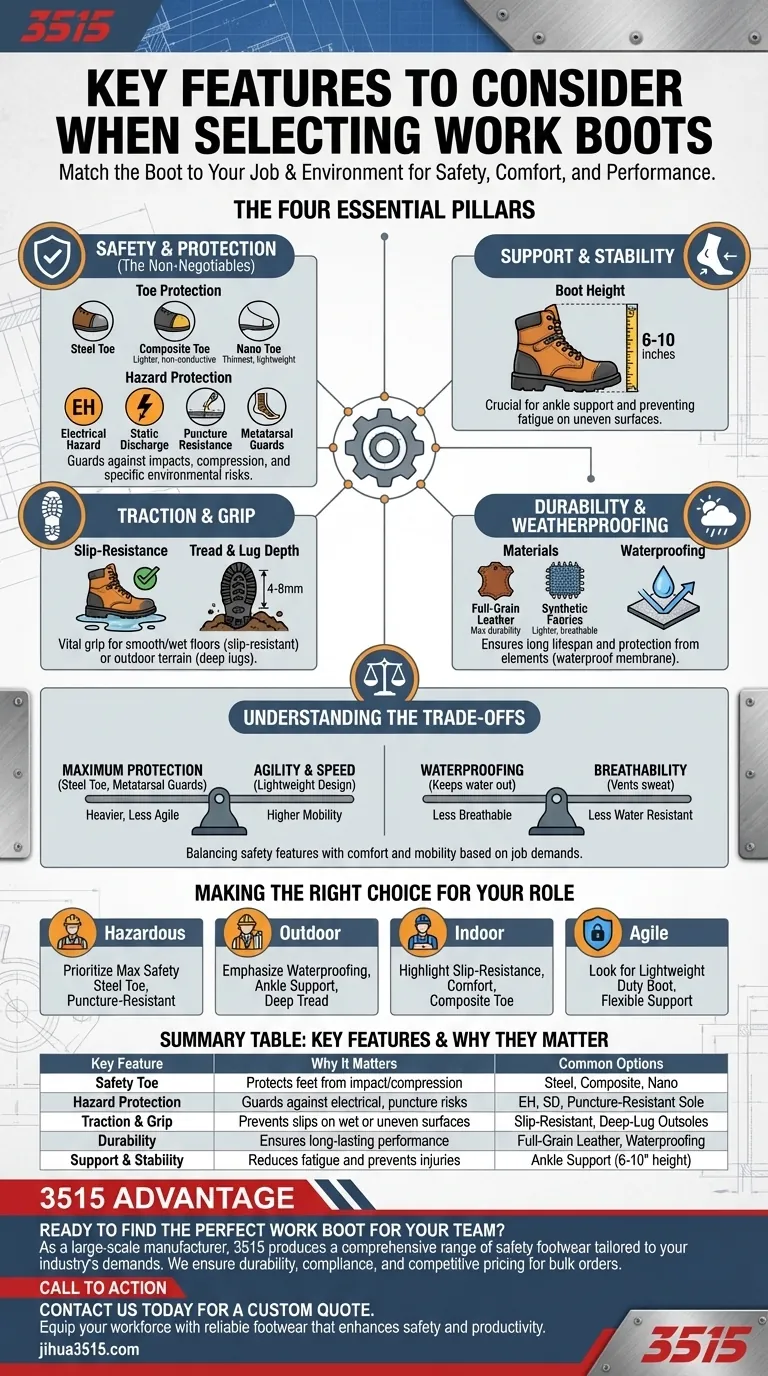

Safety and Protection (The Non-Negotiables)

This is the most critical category, directly addressing workplace hazards.

Toe Protection is the most well-known safety feature.

- Steel Toe: Offers maximum protection against impact and compression.

- Composite Toe: Lighter than steel, does not conduct electricity or temperature, and is ideal for metal-free environments.

- Nano Toe: The most lightweight and thinnest option, offering high-impact resistance without the bulk.

Specialized Hazard Protection addresses environmental risks.

- Electrical Hazard (EH): Rated to protect you from open circuits under specific conditions. Essential for electricians or anyone working near live conductors.

- Static Discharge (SD): Reduces the buildup of static electricity, protecting sensitive electronic equipment.

- Puncture Resistance: A plate in the midsole protects your foot from sharp objects like nails.

- Metatarsal Guards: These provide an extra layer of protection for the top of your foot from heavy falling objects.

Support and Stability

Proper support is crucial for preventing fatigue and musculoskeletal injuries during long shifts.

Boot Height plays a significant role in stability. Heights of 6 to 10 inches provide excellent ankle support, which is critical on uneven or shifting surfaces.

Traction and Grip

The outsole of the boot determines its ability to grip various surfaces.

Slip-Resistance is vital for anyone working on smooth, wet, or oily floors. Look for boots specifically rated for this.

Tread and Lug Depth are key for outdoor work. Deeper lugs, between 4mm and 8mm, with a multi-directional pattern provide superior grip on dirt, mud, and rough terrain.

Durability and Weatherproofing

The boot's materials determine its lifespan and ability to protect you from the elements.

Upper Materials like full-grain leather offer maximum durability and can be treated for water resistance. Synthetic fabrics can provide a lighter, more breathable option.

Waterproofing is a distinct feature that uses a membrane to keep your feet dry in wet conditions, a must for many outdoor jobs.

Understanding the Trade-offs

No single boot excels in every category. Making an informed choice means understanding the inherent trade-offs between different features.

Maximum Protection vs. Agility

Heavy-duty boots with steel toes, metatarsal guards, and puncture-resistant soles offer the highest level of protection. However, these features add significant weight and bulk, which can reduce mobility and increase fatigue over a long day.

Steel Toe vs. Composite Toe

Steel toes provide the ultimate impact resistance but are heavy and conduct heat and cold. Composite toes are much lighter and won't transfer temperature, but they can be slightly bulkier than steel to achieve the same safety rating.

Waterproofing vs. Breathability

A fully waterproof boot is excellent for keeping water out, but it can also trap sweat and moisture inside. This can lead to discomfort, especially in warm conditions. Many boots attempt to balance this with breathable waterproof membranes.

Making the Right Choice for Your Role

Your final decision should be guided by the primary demands of your job.

- If your primary focus is hazardous environments (construction, heavy industry): Prioritize maximum safety features like steel toes, puncture-resistant soles, and metatarsal guards.

- If your primary focus is outdoor and varied terrain (surveying, landscaping): Emphasize waterproofing, excellent ankle support from a taller boot, and deep, aggressive tread for traction.

- If your primary focus is indoor and slick surfaces (mechanics, warehousing): Highlight certified slip-resistance, comfort, and a lightweight design with a composite toe to minimize fatigue.

- If your primary focus is agility and speed (law enforcement, security): Look for a lightweight "duty boot" with a multi-directional tread pattern and flexible ankle support.

Investing in the right work boot is a direct investment in your daily safety, comfort, and long-term health on the job.

Summary Table:

| Key Feature | Why It Matters | Common Options |

|---|---|---|

| Safety Toe | Protects feet from impact/compression | Steel, Composite, Nano |

| Hazard Protection | Guards against electrical, puncture risks | EH, SD, Puncture-Resistant Sole |

| Traction & Grip | Prevents slips on wet or uneven surfaces | Slip-Resistant, Deep-Lug Outsoles |

| Durability | Ensures long-lasting performance | Full-Grain Leather, Waterproofing |

| Support & Stability | Reduces fatigue and prevents injuries | Ankle Support (6-10" height) |

Ready to find the perfect work boot for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, tailored to meet the specific demands of your industry—from maximum protection for heavy industry to agile designs for security personnel.

We ensure durability, compliance with safety standards, and competitive pricing for bulk orders. Let us help you equip your workforce with reliable footwear that enhances safety and productivity.

Contact us today for a custom quote and discover the 3515 advantage.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What is a key advantage of PVC work boots regarding moisture? Unmatched Waterproof Protection

- What features should junk removal workers look for in work boots? A Guide to Safety & Comfort

- Which material is recommended for work boots in cold, wet environments? Neoprene for Superior Warmth

- What is the role of industrial footwear within the PPE framework of a palm oil refinery? Expert Safety Guide

- What are the main benefits of Wellington work boots? Unmatched Waterproofing & Slip-On Convenience

- What are the disadvantages of Rubber work boots? Understand the Trade-offs in Comfort & Durability

- How does breathable vs waterproof material in boots affect foot hygiene? Optimize Protection and Worker Health

- How does the height of PVC work boots affect their protective capabilities? Find the Perfect Balance for Your Job