When selecting safety boots, the primary features to evaluate are the type of protective toe cap, the sole's slip resistance and puncture protection, specific hazard ratings for your environment, and the overall fit and material construction for long-term comfort and durability.

The most effective safety boot isn't the one with the most features, but the one with the right features for your specific work environment. A thorough hazard assessment of your job site is the true first step in making a safe and effective choice.

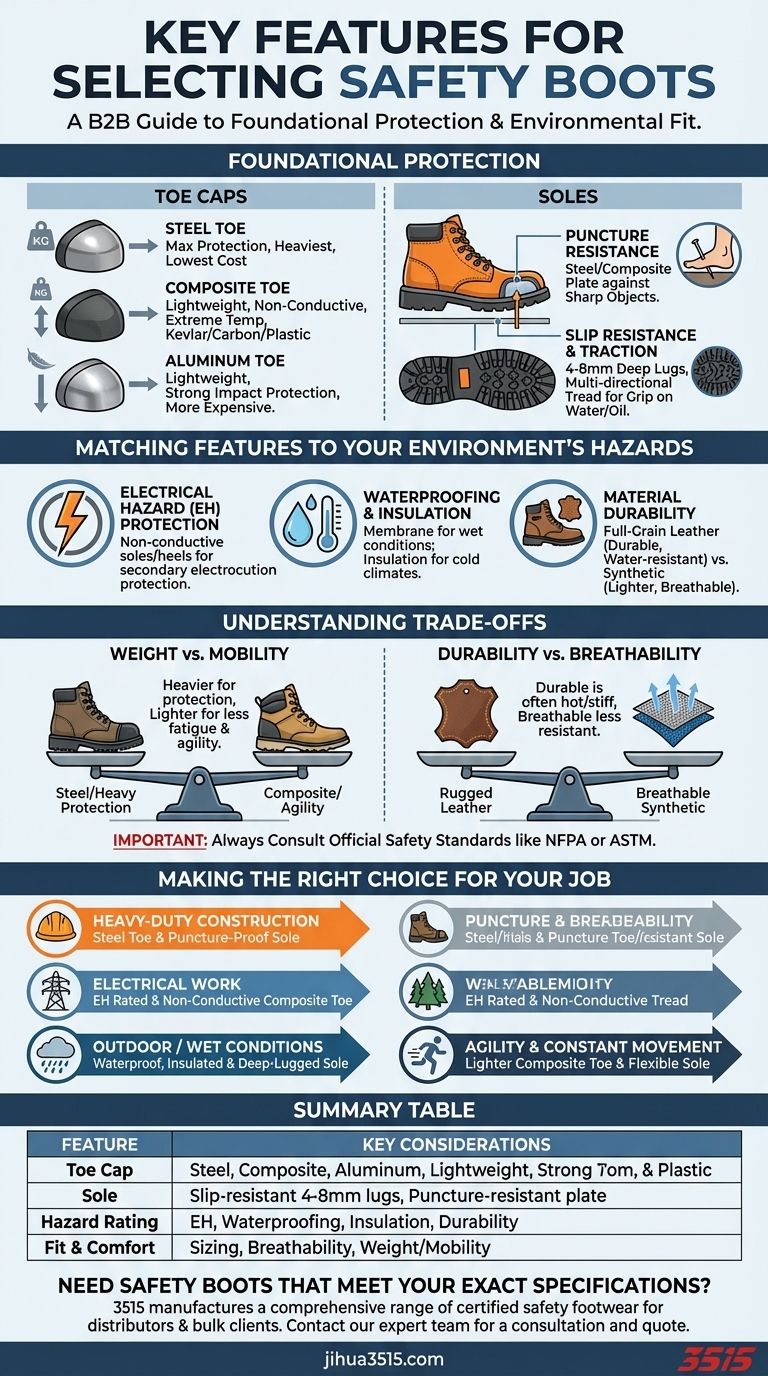

Foundational Protection: Toe Caps and Soles

The core function of any safety boot is to protect your feet from immediate, physical harm. This starts with the toe cap and the sole.

Choosing the Right Toe Cap

The protective toe cap is designed to resist impacts from falling objects. The material used has significant trade-offs in weight and conductivity.

- Steel Toes are the traditional standard, offering maximum protection against impact and compression. They are often the most affordable but also the heaviest option.

- Composite Toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, do not conduct electricity, and are better suited for extreme temperatures.

- Aluminum Toes offer a middle ground. They are lighter than steel but provide comparable impact protection, though they are often more expensive.

Understanding Puncture Resistance

For environments with sharp objects like nails or scrap metal, a puncture-resistant sole is non-negotiable. This feature typically involves a steel or composite plate embedded in the midsole to prevent objects from piercing through to your foot.

Analyzing Slip Resistance and Traction

Slips, trips, and falls are among the most common workplace accidents. The outsole of your boot is your first line of defense.

Look for deep lugs—typically 4mm to 8mm—and a multi-directional tread pattern. This design maximizes grip by channeling water and oil away from the contact surface, ensuring stable footing on varied terrain.

Matching Features to Your Environment's Hazards

Beyond basic impact protection, your boots must be suited to the specific dangers of your job site.

Electrical Hazard (EH) Protection

If you work near live electrical circuits, Electrical Hazard (EH) rated boots are essential. These are constructed with non-conductive soles and heels to provide a secondary source of protection against electrocution.

Waterproofing and Insulation

For those working outdoors or in wet conditions, waterproofing is critical for both comfort and health. Look for boots with a waterproof membrane or liner.

In cold climates, insulation provides necessary warmth to prevent cold-related injuries and maintain comfort during long shifts.

Material Durability

The boot's upper material dictates its durability, breathability, and resistance to elements.

Full-grain leather is highly durable, water-resistant, and can be conditioned for a long lifespan. Synthetic fabrics are often lighter and more breathable but may offer less durability in abrasive environments.

Understanding the Trade-offs

Selecting the perfect boot always involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Weight vs. Mobility

Heavier boots with steel components may offer maximum protection, but they can cause fatigue and reduce agility over a long day. For jobs requiring constant movement, a lighter composite-toe boot might be a better choice.

Durability vs. Breathability

Rugged, thick materials like full-grain leather are incredibly durable but can be hot and less flexible. More breathable synthetic materials may be more comfortable in warm environments but might not withstand harsh, abrasive conditions.

The Importance of Regulations

Never overlook official safety standards. Consult your industry's requirements, such as NFPA (National Fire Protection Association) or ASTM (American Society for Testing and Materials) ratings, to ensure your choice is compliant and certified for the hazards you face.

Making the Right Choice for Your Job

Your final decision should be guided by the unique demands of your work.

- If your primary focus is heavy-duty construction: Prioritize maximum impact resistance with a steel toe cap and a puncture-proof sole.

- If your primary focus is electrical work: Ensure the boots are explicitly rated for Electrical Hazard (EH) protection and feature non-conductive composite toes.

- If your primary focus is outdoor or wet conditions: Look for guaranteed waterproofing, appropriate insulation, and a deep-lugged outsole for superior traction.

- If your primary focus is agility and constant movement: Consider lighter composite toe caps and a flexible sole design to reduce fatigue and improve mobility.

Investing the time to match your boots to your specific hazards is the most critical safety decision you can make for yourself on the job.

Summary Table:

| Feature | Key Considerations |

|---|---|

| Toe Cap | Steel (max protection), Composite (lightweight, non-conductive), Aluminum (lightweight & strong) |

| Sole | Slip resistance (4-8mm lugs), Puncture-resistant plate (steel/composite) |

| Hazard Rating | Electrical Hazard (EH), Waterproofing, Insulation, Material Durability |

| Fit & Comfort | Proper sizing, material breathability, weight vs. mobility trade-offs |

Need Safety Boots That Meet Your Exact Specifications?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We can help you source or create the perfect boot—whether you need steel toes for heavy construction, EH-rated boots for electrical work, or lightweight composites for agile movement.

Contact our expert team today for a consultation and get a quote tailored to your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- What is the purpose of front hardeners in safety shoes? Essential Protection for Construction & Welding

- What is the primary purpose of safety shoes? Your Ultimate Guide to Workplace Foot Protection

- What are the advantages of composite toe boots over steel or alloy toe boots? Lightweight, Non-Conductive Safety

- What are the slip resistance requirements for safety boots? Professional Grip Standards for Poultry Facility Cleaning

- What is the core function of the FEPP flowchart? Optimize Safety Footwear Protocols with Real-Time Fatigue Data

- Which type of firefighters are required to use leather fire boots and why? Essential Gear for Wildland Safety

- How do high-traction, slip-resistant outsoles on safety boots contribute to worker safety in mines? | Prevent Mining Falls

- What are alloy toe shoes? Lightweight Protection for All-Day Comfort