At its core, the primary difference is the material used for the protective toe cap. Steel toe boots use a heavy-duty steel cap, while composite toe boots use non-metal materials like carbon fiber, plastic, or Kevlar. This single difference in material creates a cascade of distinct trade-offs in weight, conductivity, and cost.

The decision between steel and composite toe boots is not about which is universally "better," but which set of compromises best aligns with your specific work environment and physical needs. Steel prioritizes maximum impact resistance and affordability, while composite prioritizes lightweight comfort and environmental insulation.

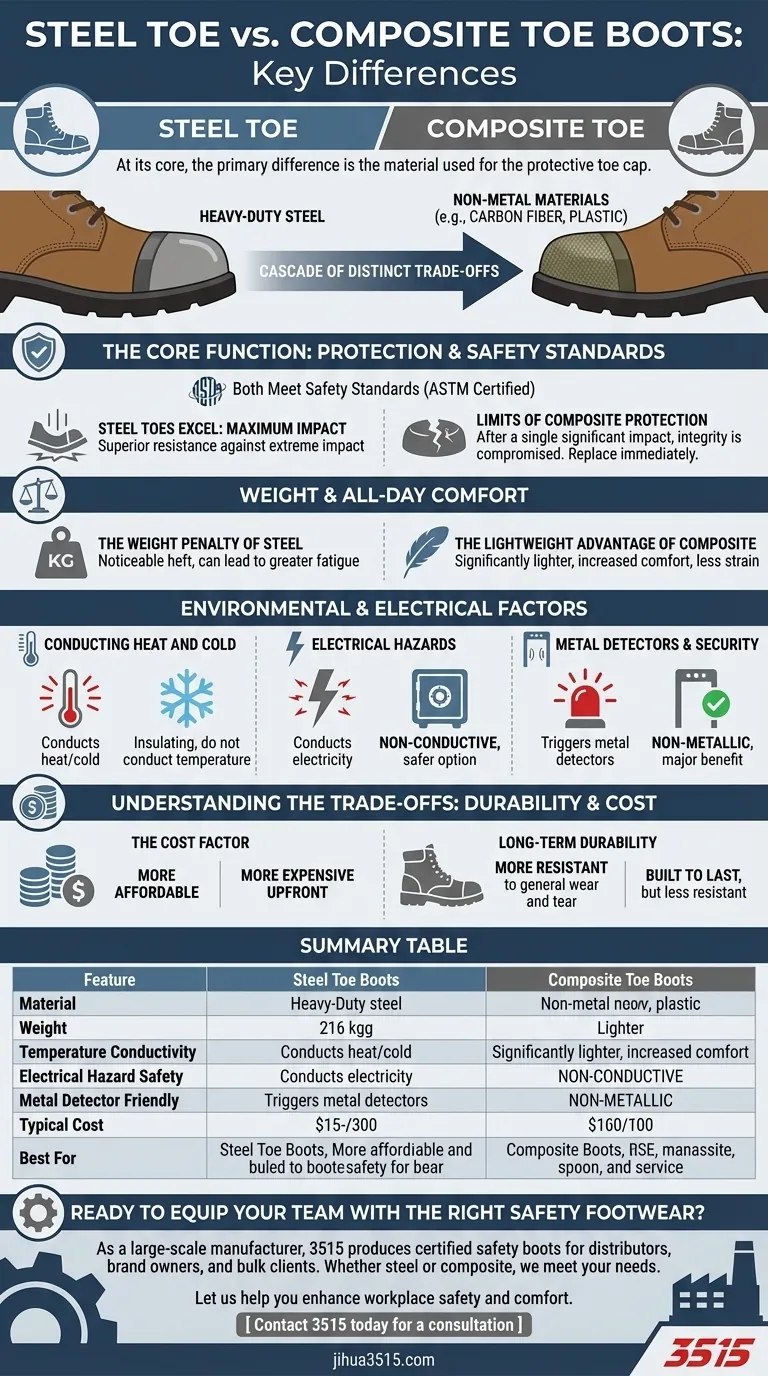

The Core Function: Protection and Safety Standards

Both steel and composite toe boots are engineered to protect you from workplace hazards. The key is understanding the subtle but important differences in their protective capabilities.

Do Both Meet Safety Standards?

Yes. To be sold as safety footwear, both types of boots must meet the performance requirements set by organizations like the American Society for Testing and Materials (ASTM). This means both have been tested and certified to withstand specific levels of impact and compression.

Where Steel Toes Excel: Maximum Impact

Steel is inherently stronger and more durable than composite materials. For this reason, steel toes offer superior resistance against extreme impact, crushing forces, and sharp objects. They are the traditional choice for the most hazardous environments.

The Limits of Composite Protection

While composite toe caps meet official safety standards, they may not withstand the same level of ultimate impact as steel. After a single, significant impact, a composite cap's integrity can be compromised, and it should be replaced immediately.

Weight and All-Day Comfort

For professionals who are on their feet all day, the weight of their boots has a significant impact on fatigue and overall comfort.

The Weight Penalty of Steel

The primary drawback of steel toe boots is their weight. The steel cap adds noticeable heft, which can lead to greater fatigue over the course of a long shift.

The Lightweight Advantage of Composite

Composite materials are significantly lighter than steel. This reduction in weight translates directly to increased comfort, less strain on your legs and back, and improved mobility throughout the workday.

Environmental and Electrical Factors

Your work environment often dictates which boot is the more practical and safer choice. Factors like temperature, electrical risk, and security screenings are critical.

Conducting Heat and Cold

Steel is an excellent thermal conductor. This means in very cold weather, the steel cap can become extremely cold, and in hot environments, it can retain heat, leading to discomfort.

The Insulating Properties of Composite

Composite materials do not conduct temperature effectively. This makes them a far more comfortable choice for anyone working outdoors or in environments with extreme hot or cold conditions.

Electrical Hazards

Because steel conducts electricity, steel toe boots should never be the primary choice for electricians or anyone working in an environment with a high risk of electrical hazards. Composite toe boots are non-conductive, making them the appropriate and safer option.

Metal Detectors and Security

The non-metallic nature of composite toe boots is a major benefit for professionals who must pass through metal detectors frequently, such as airport personnel or those in secure facilities.

Understanding the Trade-offs: Durability and Cost

Beyond the immediate functional differences, you must consider the long-term value and investment.

The Cost Factor

Generally, traditional steel toe boots are more affordable. The advanced, lightweight materials used in composite toe caps make them a more expensive option upfront.

Long-Term Durability

While both are built to last, steel caps themselves are more resistant to general wear and tear over time. They are exceptionally durable and have a long history of performance in rugged industries.

Making the Right Choice for Your Work

To select the right boot, you must prioritize the demands of your job.

- If your primary focus is maximum impact protection and budget: Choose steel toe boots for their superior strength in construction, logging, and heavy industrial settings.

- If your primary focus is all-day comfort and reduced fatigue: Choose composite toe boots for their lightweight construction, ideal for warehouse work or long shifts on your feet.

- If your primary focus is working around electricity or in extreme temperatures: Choose composite toe boots for their non-conductive and insulating properties.

- If your primary focus is passing through metal detectors frequently: Choose composite toe boots to avoid the hassle and comply with security requirements.

Ultimately, choosing the right safety boot is about selecting the correct tool for your specific professional environment.

Summary Table:

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Material | Heavy-duty steel | Non-metal (e.g., carbon fiber, plastic) |

| Weight | Heavier | Lighter |

| Temperature Conductivity | Conducts heat/cold | Insulating |

| Electrical Hazard Safety | Conductive | Non-conductive |

| Metal Detector Friendly | No | Yes |

| Typical Cost | More affordable | More expensive |

| Best For | Maximum impact protection, budget | Lightweight comfort, extreme temperatures, electrical work |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Whether your priority is the superior impact resistance of steel toe or the lightweight, non-conductive advantages of composite toe, we have the production capabilities and expertise to meet your specific needs.

Let us help you enhance workplace safety and comfort.

Contact 3515 today for a consultation to discuss your bulk footwear requirements and discover how our manufacturing solutions can benefit your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs

- Can steel toe boots be worn in hot conditions? Yes, with the right breathable design.

- What common myth about steel toe caps is addressed in the article? Debunking the Amputation Fear

- What is the primary function of reinforced steel toe caps in industrial safety shoes? Protect Workers from Stone Impacts

- What are the most common types of safety toe caps? Choose the Right Protection for Your Job

- What is the difference between safety toe and steel toe work boots? Choose the right protection for your job.

- What is the significance of composite or steel toe protection in work boots? Ensure Maximum Foot Safety & Comfort

- How much weight can steel toe work boots withstand? Unpacking the 3,372 lb. Safety Standard