At their core, motorcycle boots are purpose-built safety equipment, while regular boots are designed for walking, work, or fashion. The key differences lie in specialized protective features like reinforced ankle, heel, and toe boxes, abrasion-resistant materials, and anti-twist construction, all of which are absent in standard footwear.

The crucial distinction is this: A work boot or tactical boot is designed to protect you from the environment you walk in. A motorcycle boot is designed to protect you from the motorcycle itself and the road during a crash.

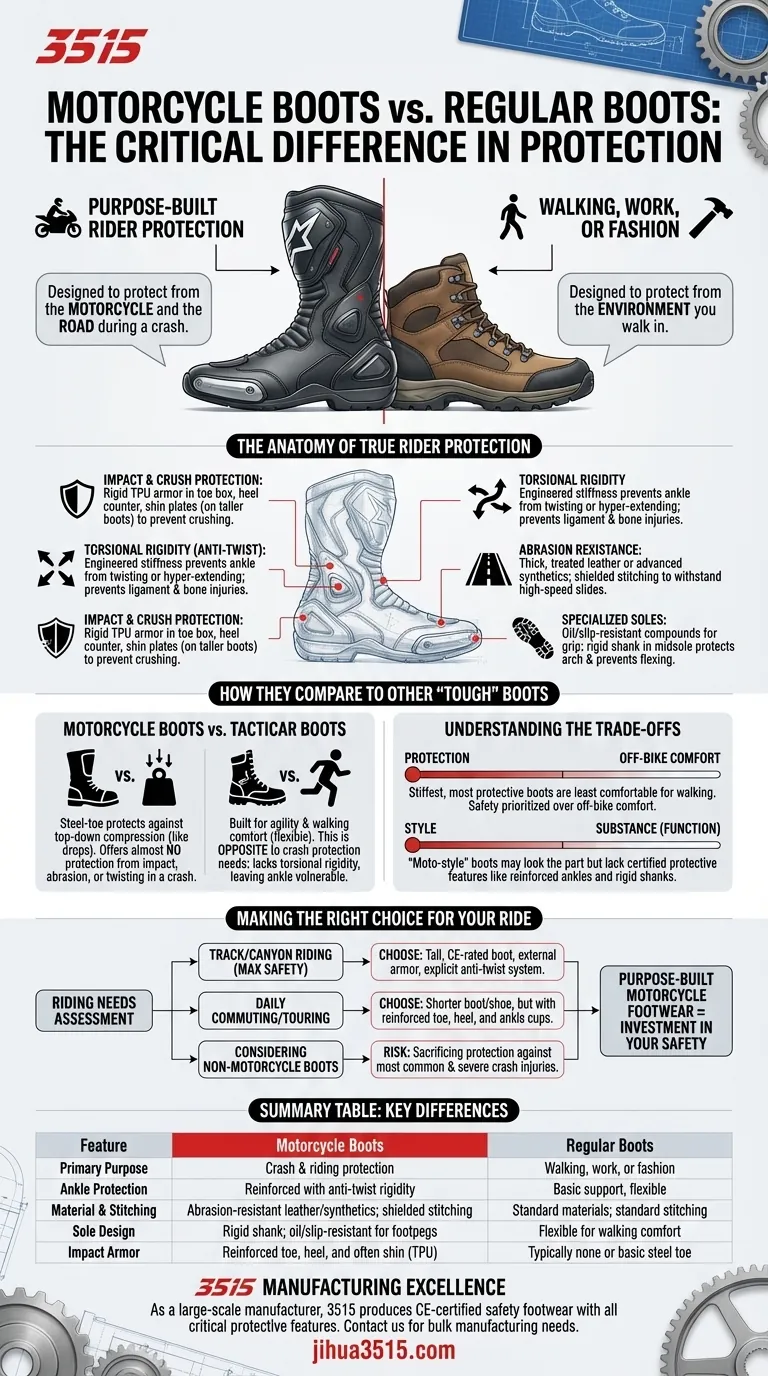

The Anatomy of True Rider Protection

To understand the difference, you must look at a motorcycle boot not as footwear, but as a piece of technical safety gear. Each component is engineered to mitigate specific forces encountered in a crash.

Impact and Crush Protection

True motorcycle boots incorporate rigid armor, often in the form of thermoplastic polyurethane (TPU), over critical areas. This includes a reinforced toe box, a heel counter, and often shin plates on taller boots.

This armor is designed to protect your foot from being crushed by the weight of the bike or from direct impact with the road or another object.

Torsional Rigidity (Anti-Twist)

This is perhaps the most critical feature absent in all other boots. Motorcycle boots are engineered to be stiff, preventing your ankle from twisting, hyper-extending, or bending in unnatural directions during a tumble.

While this makes them less comfortable for walking, this rigidity is what saves you from debilitating ligament and bone injuries.

Abrasion Resistance

Regular leather or textile will shred in seconds when sliding across asphalt. Motorcycle boots use thick, specially treated leather or advanced synthetic materials designed to withstand high-speed abrasion.

Stitching is also heavy-duty and often shielded to prevent it from bursting on impact, which would cause the boot to fall apart when you need it most.

Specialized Soles

The sole of a riding boot is a functional component. It is made from oil-resistant and slip-resistant compounds to ensure a secure grip on the footpegs and on the pavement when you stop.

They also feature a rigid shank embedded in the midsole, which prevents the boot from flexing over the footpeg and protects the arch of your foot from impact.

How They Compare to Other "Tough" Boots

Many people assume that a sturdy work boot or tactical boot offers adequate protection. This is a dangerous misconception.

Motorcycle Boots vs. Work Boots

A steel-toe work boot is designed to protect against top-down compression, like a heavy object being dropped on your foot. It offers almost no protection from the impact, abrasion, and twisting forces of a motorcycle crash. Their soles and laces are not designed for riding.

Motorcycle Boots vs. Tactical Boots

Tactical boots are built for agility, flexibility, and comfort while walking or running. This design principle is the direct opposite of what is required for motorcycle protection. Their lightweight flexibility offers no torsional rigidity, leaving your ankle vulnerable.

Understanding the Trade-offs

Choosing the right gear always involves balancing competing needs. It is essential to understand what you are giving up for what you gain.

Protection vs. Off-Bike Comfort

The stiffest, most protective boots are often the least comfortable for walking. This is not a design flaw; it is a deliberate choice to prioritize your safety on the bike over your comfort off of it.

Style vs. Substance

Many manufacturers sell "moto-style" fashion boots. These boots may look the part but lack any of the certified protective features like reinforced ankles, rigid shanks, or proper abrasion-resistant construction. They offer a look, not a function.

Making the Right Choice for Your Ride

Your choice of footwear should be dictated by your riding needs and an honest assessment of the risks involved.

- If your primary focus is maximum safety for track or canyon riding: Choose a tall, CE-rated boot with external armor and an explicit anti-twist system.

- If your primary focus is daily commuting or touring: Look for a shorter, more understated riding boot or shoe that still clearly features a reinforced toe, heel, and ankle cups.

- If you are considering using non-motorcycle boots: Recognize that you are sacrificing protection against the most common and severe foot and ankle injuries in a crash.

Ultimately, investing in purpose-built motorcycle footwear is a direct investment in your own safety and ability to continue riding.

Summary Table:

| Feature | Motorcycle Boots | Regular Boots |

|---|---|---|

| Primary Purpose | Crash & riding protection | Walking, work, or fashion |

| Ankle Protection | Reinforced with anti-twist rigidity | Basic support, flexible |

| Material & Stitching | Abrasion-resistant leather/synthetics; shielded stitching | Standard materials; standard stitching |

| Sole Design | Rigid shank; oil/slip-resistant for footpegs | Flexible for walking comfort |

| Impact Armor | Reinforced toe, heel, and often shin (TPU) | Typically none or basic steel toe |

As a large-scale manufacturer, 3515 produces a comprehensive range of CE-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective motorcycle boots engineered with the critical features outlined above. Ensure your customers are equipped with genuine rider protection – contact us today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What core issue does the Hull-type structure design solve? Power Your Footwear with Force Amplification Technology

- How does drying boots and socks promptly help in winter? Prevent Cold & Protect Your Gear

- What are the technical advantages of TPU for inflatable insoles? Unlocking Superior Durability and Pressure Relief

- How do industrial embossing machines and mold plates modify leather? Master Surface Consistency and Aesthetic Appeal

- What is the primary role of thin-film pressure sensors in a single-leg exoskeleton? Mastering Gait Phase Control

- Why do quality shoes boost confidence? Unleash Your Potential with the Right Footwear

- How does a standardized physical environment contribute to the data accuracy of digital sensor footwear? Boost Precision

- What are the overall benefits of following these boot care tips? Protect Your Investment & Well-being