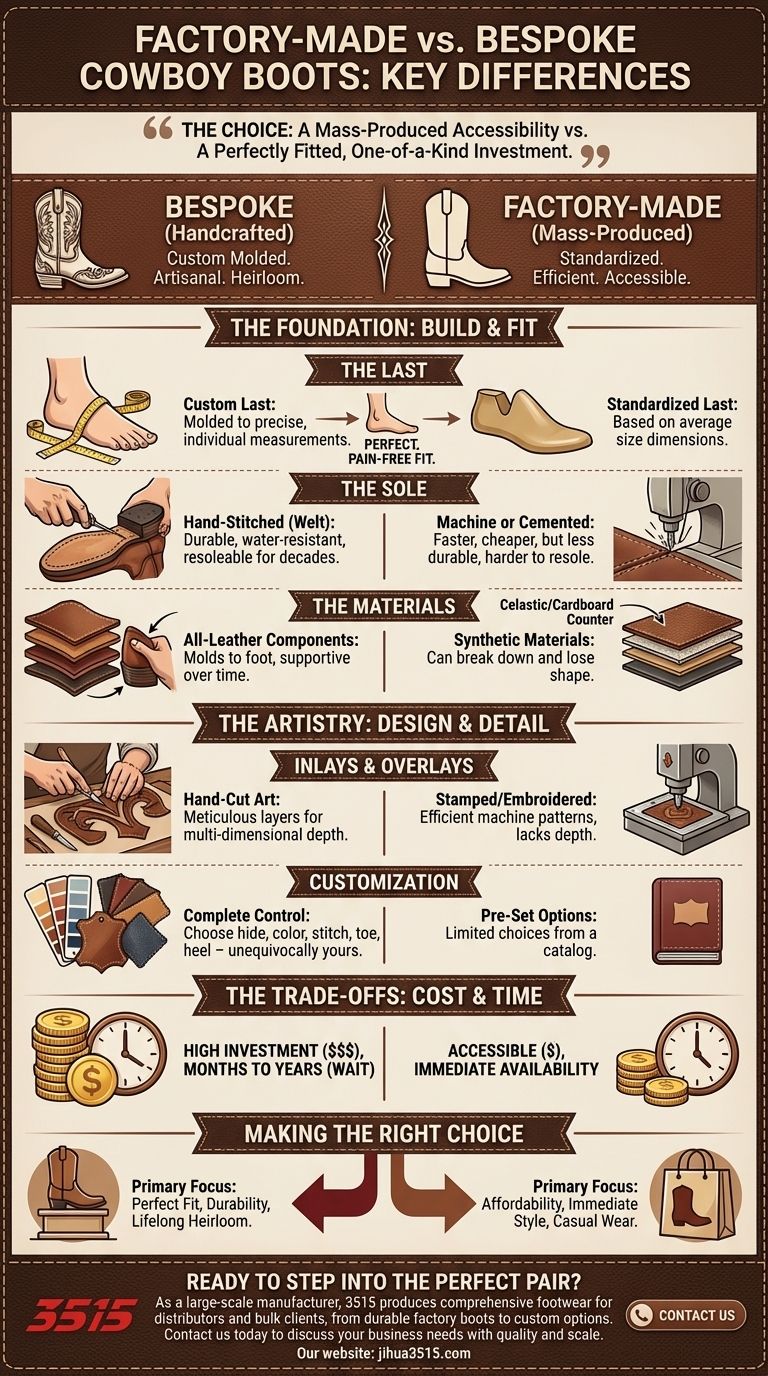

The fundamental difference between factory-made and bespoke cowboy boots lies in their creation process, which directly impacts fit, artistry, and longevity. Factory boots are built around standardized sizes for mass production, while bespoke boots are meticulously handcrafted around a personalized mold—a "last"—made from the exact measurements of your individual feet.

The choice is not simply between two types of boots, but between two philosophies: the immediate accessibility of a mass-produced product versus the long-term investment in a perfectly fitted, one-of-a-kind piece of wearable art.

The Foundation: How the Boot is Made

The core differences begin at the structural level. A boot's construction dictates its comfort, durability, and how it conforms to your foot over time.

The Last: A Personalized Blueprint vs. a Standard Size

A last is the three-dimensional form that a boot is built around. It determines the final shape and fit.

In the bespoke process, the bootmaker takes dozens of precise measurements of your feet to create a custom last. This unique blueprint accounts for every nuance, from arch height to the specific shape of your toes.

Factory-made boots use standardized lasts based on average foot dimensions for a given size. This is why one brand's size 10 can feel completely different from another's.

The Sole: Hand-Stitched Durability

The method of attaching the sole to the boot is a key indicator of quality.

Bespoke boots almost always feature hand-stitched welts and soles. This traditional method, often using lemonwood pegs and heavy thread, creates an incredibly durable and water-resistant bond that can be rebuilt by a skilled cobbler for decades of use.

Many factory boots use cement (glue) or rapid machine stitching to attach soles, which is faster and cheaper but less durable and harder to properly resole.

The Materials: Hand-Selected vs. Mass-Produced

Internal components you can't see often have the biggest impact on long-term comfort and structure.

True bespoke boots use high-quality, all-leather components, including the counter (the stiffener around the heel). A leather counter molds to your heel over time for a perfect, supportive fit.

To reduce costs, factory boots often use celastic or cardboard counters, which can break down and lose their shape more quickly.

The Artistry: Visual and Design Differences

Beyond the fit, the aesthetic execution sets bespoke and factory boots worlds apart. The design on a bespoke boot is not just decoration; it's a form of high craft.

Inlays and Overlays: Hand-Cut Art vs. Stamped Patterns

The intricate patterns on high-end boots are created with layers of leather.

Bespoke artisans meticulously hand-cut, skive (thin), and stitch numerous small pieces of leather together to create complex imagery. This process allows for incredible detail and depth.

Factory boots typically rely on machine embroidery or stamped designs that press a pattern into the leather. While effective, this lacks the unique, multi-dimensional quality of hand-tooled inlay work.

Complete Customization: Your Vision, Realized

With a factory boot, you choose from a catalog of pre-set options.

The bespoke process gives you complete control. You collaborate with the maker to select the exact hide, color, stitch pattern, toe shape, heel height, and decorative theme, resulting in a boot that is unequivocally yours.

Understanding the Trade-offs

Choosing between these options requires acknowledging the practical realities of cost, time, and accessibility. This is where objectivity is crucial.

Cost: A Significant Investment

There is a substantial price difference. A pair of bespoke boots represents a significant financial investment, often costing several thousand dollars due to the hundreds of hours of skilled labor involved.

Factory-made boots are far more accessible, with prices ranging from a couple hundred to several hundred dollars for high-quality production models.

Time: The Wait for Perfection

Patience is a prerequisite for bespoke. The waiting list for a renowned bootmaker can be months or even years long.

Factory boots offer instant gratification. You can walk into a store or order online and have them within days.

Making the Right Choice for Your Goal

The "better" boot is the one that aligns with your specific needs, budget, and priorities.

- If your primary focus is a perfect, pain-free fit due to unique foot shapes: A bespoke boot is the only way to achieve a truly custom-molded fit.

- If your primary focus is durability and creating a lifelong heirloom: The superior materials and hand-welted construction of a bespoke boot are unmatched.

- If your primary focus is affordability and immediate availability for style or casual wear: A well-made factory boot from a reputable brand offers excellent value and function.

Ultimately, understanding these differences empowers you to choose the boot that best serves your purpose.

Summary Table:

| Feature | Bespoke Boots | Factory-Made Boots |

|---|---|---|

| Fit & Last | Custom-made last from precise foot measurements | Standardized last based on average sizes |

| Sole Construction | Hand-stitched welt, durable, resoleable | Cement or machine-stitched, less durable |

| Materials | All-leather components (e.g., leather counter) | May use synthetic materials (e.g., celastic counter) |

| Artistry & Design | Hand-cut inlays, full customization | Machine-stamped or embroidered patterns |

| Cost | High investment (thousands of dollars) | Accessible (hundreds of dollars) |

| Time to Acquire | Months to years (waitlist) | Immediate availability |

Ready to step into the perfect pair of boots? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether you need durable, stylish factory boots for broad distribution or are exploring custom options, our production capabilities encompass all types of shoes and boots to meet your specific needs. Contact us today to discuss how we can support your business with quality, scale, and reliability.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the functional advantages of integrating a deep heel cup design into orthopedic insoles? Maximize Foot Stability

- Why is the chilling method preferred over traditional salting for raw hide preservation in green tanning? Top Benefits

- What role do Yokoten documents play in footwear factory safety? Enhancing Standards Through Horizontal Deployment

- What is the purpose of utilizing minimally shoes during postural stability testing on inclines? Unlock Pure Biomechanics

- What are the advantages of embossed leather for shoes? Discover Durable, Low-Maintenance Style

- Why is durability important in shoe materials? Build Long-Term Value & Performance

- What role do portable wireless physiological monitoring devices play in simulating high-intensity rescue scenarios?

- Why is water resistance important for boots and shoes? Protect Your Feet from Moisture and Discomfort