At their core, the essential features of mining boots are a direct response to the industry's hazardous conditions. They must include robust safety toes, puncture-resistant and slip-resistant soles, and protection against electrical and heat hazards to shield workers from the severe risks inherent in mining operations.

The most effective mining boot is not simply a checklist of safety features. It is a carefully engineered tool that synthesizes non-negotiable protection with the functional comfort and support required to endure long, demanding shifts in an extreme environment.

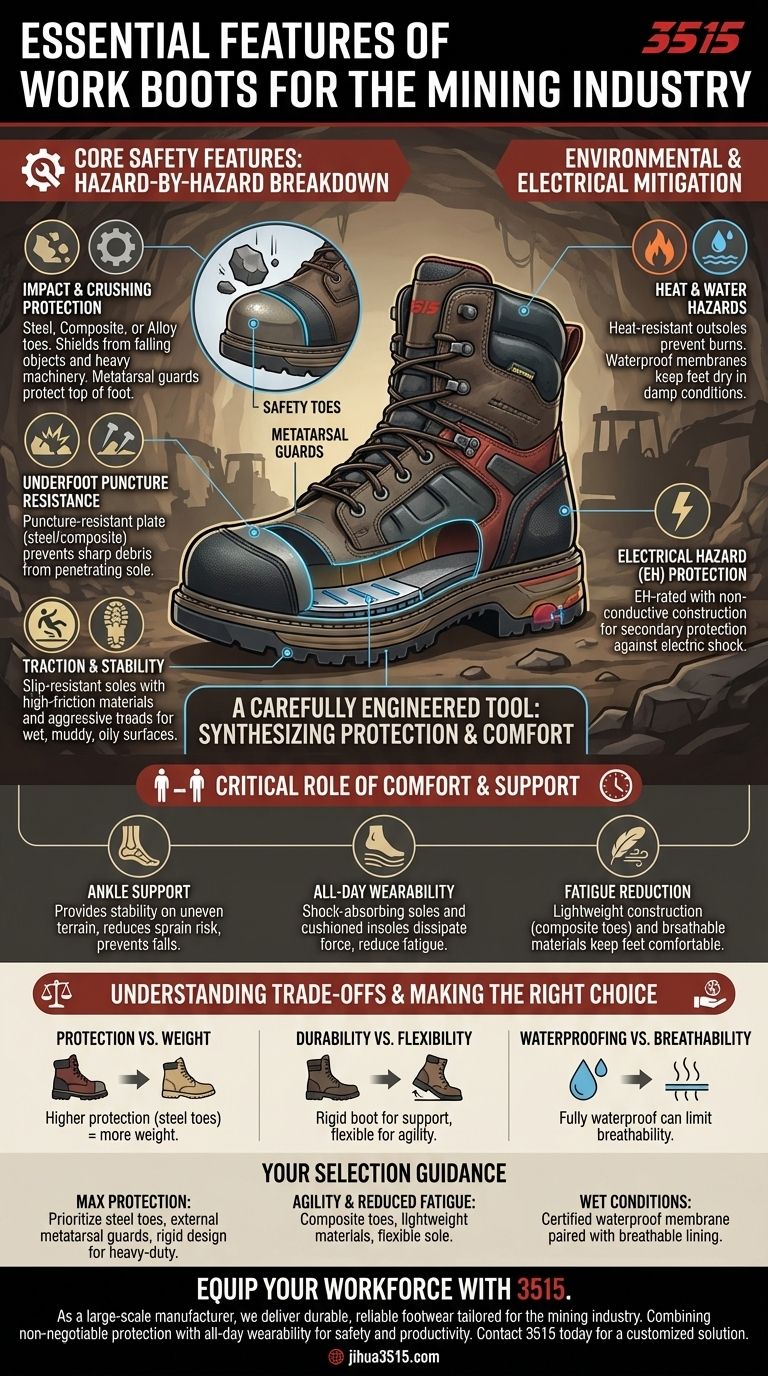

Core Safety Features: A Hazard-by-Hazard Breakdown

Understanding the specific dangers of a mining site is the key to appreciating why certain boot features are mandated. Each component is designed to mitigate a distinct and potentially severe risk.

Impact and Crushing Protection (Safety Toes & Metatarsal Guards)

The most immediate danger in many mining environments is from falling objects or interactions with heavy machinery. Safety toes are the first line of defense.

These are typically made from steel, composite, or alloy materials, all of which must meet national safety standards for impact and compression resistance.

For even greater protection, metatarsal guards shield the delicate bones on the top of the foot, an area left exposed by standard safety toes.

Underfoot Puncture Resistance

The ground in a mine is often littered with sharp debris, from jagged rocks to metal fragments.

A puncture-resistant plate, typically made of steel or a composite fabric, is embedded in the midsole to prevent these objects from penetrating the sole and causing serious injury.

Traction and Stability (Slip-Resistant Soles)

Underground mines are frequently wet, muddy, or oily, creating treacherous surfaces. Slip-resistant soles are crucial for preventing falls.

These outsoles are made from materials with a high coefficient of friction, like rubber or polyurethane. They feature deep, aggressive treads designed to channel water and debris away, ensuring a firm grip.

Environmental Hazard Mitigation (Heat & Water)

Certain mining operations expose workers to extremely high temperatures. Heat-resistant outsoles are vital to prevent burns and sole degradation.

Conversely, many mines are perpetually damp. Waterproofing, often achieved through a sealed membrane, keeps feet dry, preventing discomfort and health issues.

Electrical Hazard (EH) Protection

The presence of heavy electrical equipment and potential for contact with live conductors creates a significant risk of electric shock.

EH-rated boots are constructed with non-conductive soles and heels, providing a secondary source of protection by insulating the wearer from the ground.

The Critical Role of Comfort and Support

While safety features are non-negotiable, a boot is ineffective if it's too uncomfortable or fatiguing to wear for a 10- or 12-hour shift. Comfort is a functional component of safety.

Ankle Support for Uneven Terrain

Miners constantly navigate unstable and uneven ground, often while carrying heavy tools.

Proper ankle support, often enhanced with internal or external heel counters, provides stability, reduces the risk of sprains, and helps prevent slips and falls.

All-Day Wearability (Cushioning & Shock Absorption)

Walking on hard, unforgiving surfaces for hours takes a toll on the body.

Shock-absorbing soles and cushioned insoles dissipate the force of each step, reducing stress on the feet, legs, and lower back.

Fatigue Reduction (Weight and Breathability)

Every ounce matters over the course of thousands of steps. Lightweight construction, using materials like composite toes instead of steel, can significantly reduce fatigue.

Breathable materials, such as leather or specialized mesh panels, allow heat and moisture to escape, keeping feet drier and more comfortable.

Understanding the Trade-offs

Selecting the perfect mining boot involves balancing competing priorities. There is no single boot that is best for every possible condition.

Protection vs. Weight

The highest levels of protection often come with a weight penalty. Steel toes and external metatarsal guards offer maximum defense but are heavier than their composite counterparts, which can increase fatigue.

Durability vs. Flexibility

A highly rigid boot provides excellent ankle support and durability but may restrict movement. A more flexible boot can enhance comfort and agility but may offer less support for carrying heavy loads over rough terrain.

Waterproofing vs. Breathability

A fully waterproof membrane is essential for wet environments but can limit breathability, trapping sweat. In a hot, dry mine, prioritizing a more breathable boot might be the better choice to manage heat and moisture from within.

Making the Right Choice for Your Goal

Your selection should be guided by the specific hazards and conditions of your work environment.

- If your primary focus is maximum protection in heavy-duty environments: Prioritize steel toes, external metatarsal guards, and a rigid, high-ankle design for superior support.

- If your primary focus is agility and reduced fatigue: Look for boots with composite safety toes, lightweight materials, and a more flexible sole construction.

- If you work in consistently wet or damp conditions: A certified waterproof membrane is non-negotiable, but ensure it is paired with quality, breathable lining materials.

Ultimately, choosing the right mining boot is a strategic safety decision that directly impacts your well-being and effectiveness on the job.

Summary Table:

| Feature Category | Key Components | Primary Benefit |

|---|---|---|

| Core Safety | Safety Toes, Puncture-Resistant Plate, Slip-Resistant Soles | Protects from impact, sharp objects, and slips |

| Hazard Mitigation | Heat/Water Resistance, Electrical Hazard (EH) Rating | Shields against extreme temperatures and electric shock |

| Comfort & Support | Ankle Support, Cushioned Insoles, Lightweight Materials | Reduces fatigue and enhances stability for long shifts |

| Material Trade-offs | Steel vs. Composite Toes, Waterproofing vs. Breathability | Balances protection, weight, and comfort for specific needs |

Equip Your Workforce with the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear tailored for the demanding conditions of the mining industry. Our boots are engineered with the essential features detailed above—robust safety toes, puncture-resistant soles, EH protection, and superior comfort—to ensure your workers are safe, productive, and supported during long shifts.

We work directly with distributors, brand owners, and bulk clients to deliver durable, reliable footwear that meets the highest safety standards. Let us help you equip your team with boots that combine non-negotiable protection with all-day wearability.

Contact 3515 today for a customized solution that meets your specific mining safety needs.

Visual Guide

Related Products

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Where can the ASTM code be found on safety toe boots? A Guide to Locating and Decoding Your Boot's Safety Label

- What are the characteristics of harness and engineer boots? Defining Two Iconic Rugged Styles

- Why is rubber a preferred material for certain work environments? Unmatched Protection Against Hazards

- What are the main characteristics of PU as a material for work boots? Lightweight, Flexible & Durable

- Which type of boot is more breathable: waterproof or water-resistant? Find Your Perfect Fit.

- What are the key features to look for in winter biking boots? Essential Guide for Warm, Dry Feet

- How should wildland firefighter boots be broken in? A Phased Guide for Safety & Performance

- What makes Western work boots durable and long-lasting? The Trifecta of Quality Materials, Repairable Construction & Design