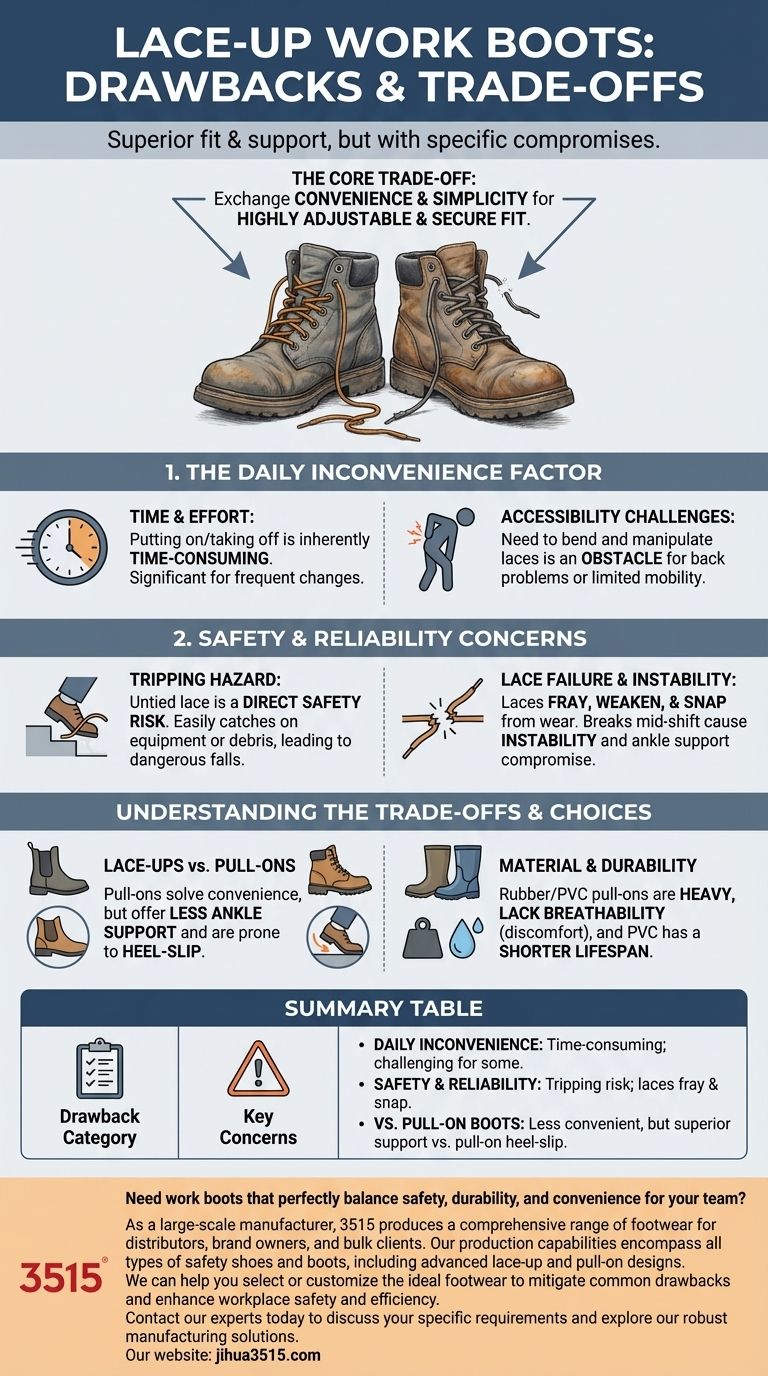

While offering superior fit and support, the primary drawbacks of lace-up work boots are centered on the laces themselves. These boots require more time to put on and take off, the laces can create tripping hazards if they come untied, and they are subject to wear and tear that can cause them to fail during the workday.

The core trade-off with lace-up boots is clear: you exchange the convenience and simplicity of other boot styles for a highly adjustable and secure fit. Understanding this exchange is crucial to deciding if their drawbacks are acceptable for your specific work environment.

The Daily Inconvenience Factor

For many workers, the most noticeable drawbacks are the ones they face every day. The design of a lace-up boot introduces small but persistent logistical challenges.

Time and Effort

Putting on and taking off lace-up boots is inherently time-consuming. This can be a significant inconvenience for professionals who are frequently in a rush or need to change footwear multiple times throughout the day.

Accessibility Challenges

The need to bend over and manipulate laces can present a genuine obstacle for individuals with back problems or limited mobility, making a simple task frustrating or difficult.

Safety and Reliability Concerns

Beyond simple inconvenience, the laces on a work boot introduce unique safety and reliability risks that are critical to consider in a professional setting.

The Risk of Tripping

An untied lace is a direct and serious safety hazard. It can easily get caught on equipment, debris, or scaffolding, leading to potentially dangerous trips and falls in an active work environment.

Lace Failure and Instability

Laces are a point of failure. Over time, they can fray, weaken, and snap from constant friction and tension. If a lace breaks mid-shift, the boot becomes loose and unstable, compromising ankle support and creating an immediate safety risk.

Understanding the Trade-offs

The disadvantages of lace-up boots only make sense when compared to the alternatives. Each boot style solves a different problem and comes with its own set of compromises.

Lace-Ups vs. Pull-Ons

Pull-on boots solve the convenience problem but often introduce others. They typically provide less ankle support and are prone to heel-slip, where your heel moves excessively inside the boot. This can make them feel less secure for tasks like climbing ladders or navigating uneven terrain.

Material and Durability

Many waterproof pull-on boots are made of rubber or PVC, which have their own drawbacks. Rubber boots can be heavy and lack breathability, causing discomfort during long periods of wear. PVC boots are often less flexible, less comfortable, and have a shorter lifespan due to lower wear resistance.

Making the Right Choice for Your Environment

Choosing the right boot is about matching the tool to the task. The drawbacks of one style may be an acceptable trade-off for the benefits it provides in your specific role.

- If your primary focus is maximum support and an adjustable fit: Choose lace-up boots, but be diligent about checking your laces for wear and keeping them tied securely.

- If your primary focus is speed and convenience for indoor or flat-ground work: Consider pull-on boots, but ensure they fit properly to minimize heel-slip and instability.

- If your primary focus is absolute waterproof or chemical protection: Opt for specialized rubber or PVC boots, but be prepared for the trade-offs in weight, breathability, and long-term comfort.

Ultimately, understanding the potential points of failure on your equipment is the first step toward a safer and more efficient workday.

Summary Table:

| Drawback Category | Key Concerns |

|---|---|

| Daily Inconvenience | Time-consuming to put on/take off; challenging for users with back problems or limited mobility. |

| Safety & Reliability | Risk of tripping from untied laces; laces can fray, weaken, and snap, causing instability. |

| Vs. Pull-On Boots | Less convenient but offers superior ankle support and a more secure fit compared to pull-ons, which can have heel-slip. |

Need work boots that perfectly balance safety, durability, and convenience for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including advanced lace-up and pull-on designs. We can help you select or customize the ideal footwear to mitigate common drawbacks and enhance workplace safety and efficiency.

Contact our experts today to discuss your specific requirements and explore our robust manufacturing solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why is keeping feet warm important during winter work? Protect Your Health and Safety on the Job

- How should you prepare leather boots for cleaning and waterproofing? A Step-by-Step Guide to Long-Lasting Protection

- What are some tips for wearing engineer boots? Master the Pants-to-Boot Silhouette

- Why is leather conditioning important for fire boots? Extend Lifespan & Ensure Safety

- How should leather work boot laces be tied for optimal care? Preserve Your Boots and Enhance Comfort

- What should be considered when choosing boots for riding and hiking? Balancing Safety, Comfort & Durability

- How do engineer boots function compared to other types of boots? A Guide to Their Unique Design & Purpose

- How do PVC boots compare to rubber boots? Choose the Right Work Boot Material