The primary disadvantages of vulcanized soles are their lack of support, minimal impact absorption, and comparatively lower overall durability. Because the construction process bakes the rubber sole directly to the shoe's upper, it results in a thin, flat profile that offers less cushioning and protection than other methods.

While prized for their flexibility and board feel, vulcanized soles achieve this by trading away the cushioning, arch support, and long-term structural integrity found in more robust shoe constructions.

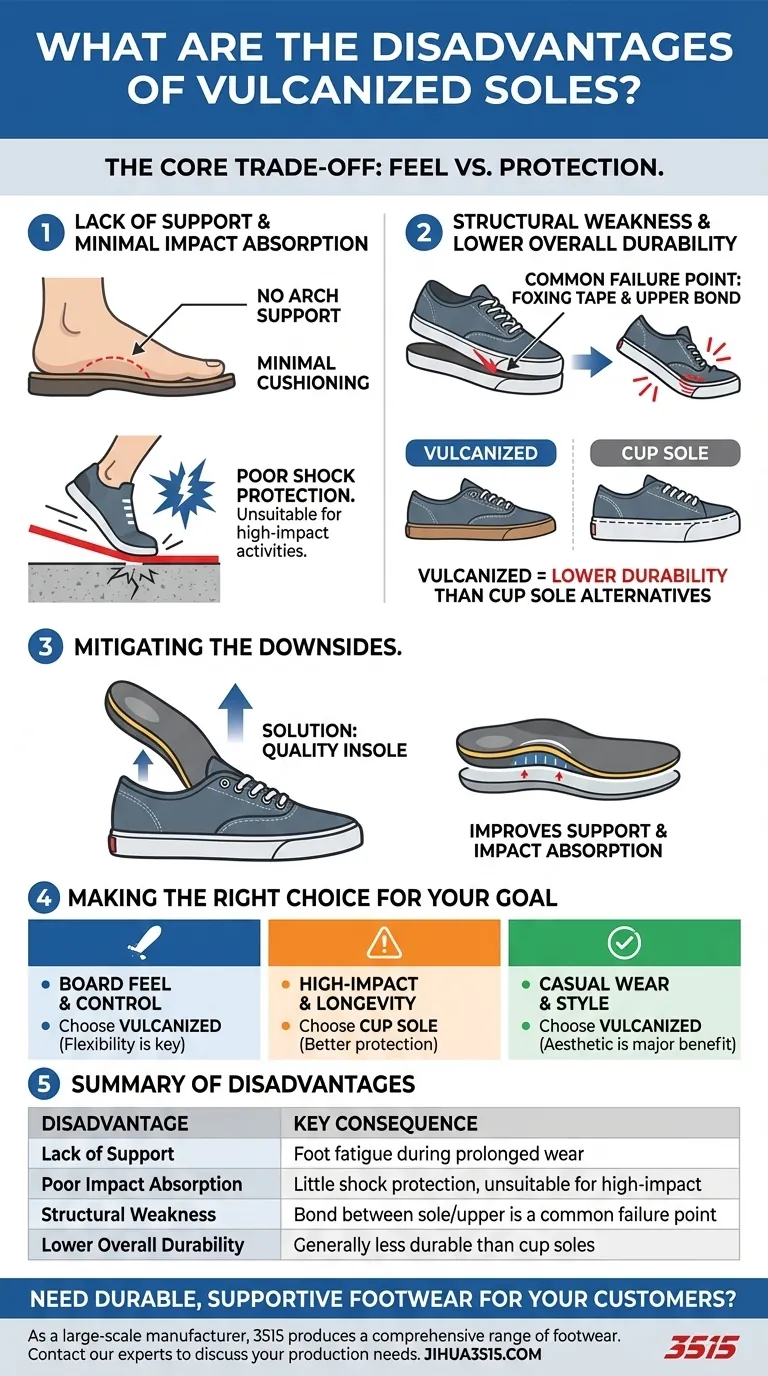

The Core Trade-Off: Feel vs. Protection

The defining characteristic of a vulcanized shoe is its thin, flexible sole, which creates a direct trade-off between the connection you feel with a surface (like a skateboard) and the protection your foot receives.

Why They Lack Support

The vulcanized construction process results in a very flat and uniform sole. This design inherently lacks the space for significant built-in arch support or advanced cushioning systems.

This minimalist structure makes the shoe feel less supportive during long periods of wear or intense activity.

The Impact Absorption Problem

The thinness of the sole is a major drawback for high-impact movements. There is very little material to absorb shock from jumps or drops.

This makes vulcanized shoes less suitable for activities like skating large stair sets or for individuals who need significant impact protection for their joints.

Flexibility's Double-Edged Sword

While supreme flexibility allows for excellent grip and a natural range of motion, it also means the shoe offers less structural rigidity.

This can contribute to foot fatigue, as your muscles have to work harder to maintain stability without the aid of a more supportive shoe structure.

Deconstructing Durability: Sole vs. Shoe

There is a common misconception about the durability of vulcanized shoes. The issue is rarely the rubber itself, but rather how the shoe is held together.

The Real Point of Failure

The most common breakage point on a vulcanized shoe is where the rubber sidewall, or foxing tape, is bonded to the canvas or suede upper.

This seam is under constant stress from flexing and is often the first part of the shoe to separate or tear, leading to premature failure.

How They Compare to Alternatives

Other construction methods, such as a cup sole, involve stitching the shoe's upper into a thick, pre-molded rubber sole. This creates a more durable mechanical bond that is generally longer-lasting than the glued-and-baked bond of a vulcanized shoe.

Mitigating the Downsides

While these disadvantages are inherent to the design, they are not always deal-breakers. The biggest weakness can be addressed with a simple addition.

The Critical Role of a Good Insole

Many of the issues related to poor cushioning and lack of support can be significantly improved by replacing the stock sock liner with a quality aftermarket insole.

A well-designed insole can provide the arch support and impact absorption that the shoe's native construction lacks, making it far more comfortable and protective for intense use.

Making the Right Choice for Your Goal

Ultimately, the choice depends entirely on what you prioritize.

- If your primary focus is board feel and technical control: The flexibility of a vulcanized sole is a key advantage, but plan on adding a supportive insole for protection.

- If your primary focus is high-impact protection and longevity: A shoe with a cup sole construction is almost always a more suitable and durable choice.

- If your primary focus is casual wear and style: The disadvantages are far less critical, and the classic, low-profile aesthetic of vulcanized shoes is a major benefit.

Understanding the fundamental exchange between surface feel and structural support is the key to choosing footwear that truly serves your purpose.

Summary Table:

| Disadvantage | Key Consequence |

|---|---|

| Lack of Support | Minimal arch support, leading to foot fatigue during prolonged wear. |

| Poor Impact Absorption | Thin sole offers little shock protection, unsuitable for high-impact activities. |

| Structural Weakness | Bond between sole and upper (foxing tape) is a common point of failure. |

| Lower Overall Durability | Vulcanized construction is generally less durable than cup sole alternatives. |

Need durable, supportive footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We can help you navigate the trade-offs between different sole constructions to deliver the perfect balance of comfort, durability, and performance for your market.

Contact our experts today to discuss your production needs and explore our capabilities.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

People Also Ask

- Why is choosing the right footwear important for outdoor activities? Enhance Performance & Safety

- What are some alternatives to hunting boots? Hiking, Rubber & Tactical Boots Explained

- Are trekking shoes worth it? Essential for Safety and Comfort on the Trail

- What is a trekking shoe? The Essential Guide to Protection & Stability

- What technical requirements are essential for outsoles in pivoting sports? Boost Grip and Lateral Stability