Beyond a simple uniform requirement, a security guard's safety boots are a critical piece of personal protective equipment. The different types are primarily classified by their toe protection material, specialized hazard resistance, and sole construction. The most common toe types are steel toe, for traditional impact resistance; alloy toe, which offers similar protection at a lighter weight; and composite toe, a modern non-metallic option ideal for passing through metal detectors.

The "best" safety boot doesn't exist in a vacuum. The right choice is always a direct reflection of your specific work environment, balancing certified protection against the daily demands of your post, from weather exposure to the number of hours spent on your feet.

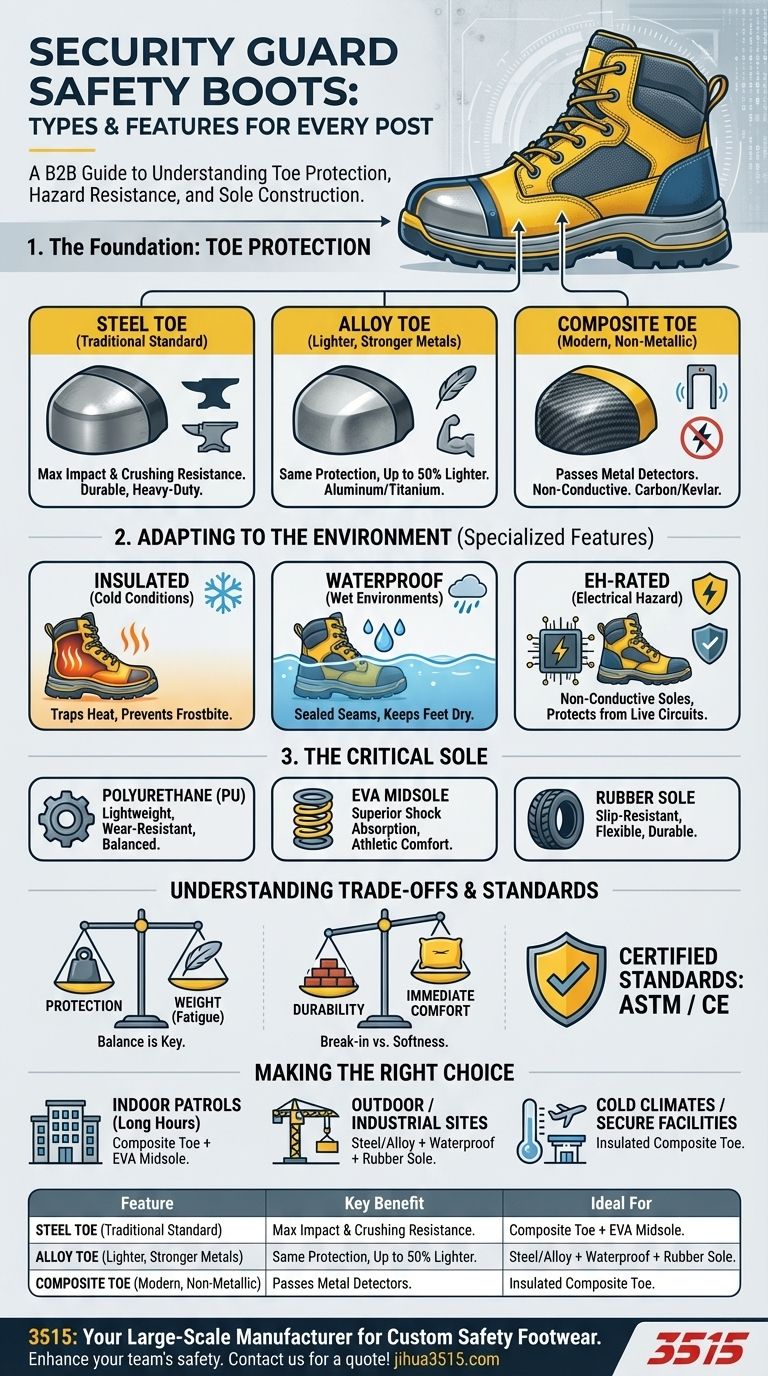

The Foundation: Understanding Toe Protection

The most defining feature of a safety boot is its protective toe cap. This is your first line of defense against impact and compression injuries from falling objects or rolling equipment.

Steel Toe: The Traditional Standard

Steel toes are the classic choice for heavy-duty protection. They are made from durable steel reinforcement that provides maximum resistance against crushing and impact forces.

They have a long-standing reputation for reliability and are often the standard in construction or industrial security settings.

Alloy Toe: Lighter, Stronger Metals

Alloy toe caps are crafted from lightweight materials like aluminum or titanium. They provide the same level of impact and compression resistance as steel but can be up to 50% lighter.

This reduction in weight can significantly decrease foot fatigue over a long shift.

Composite Toe: The Modern, Non-Metallic Option

Composite toes are made from non-metallic materials such as carbon fiber, Kevlar, plastic, or fiberglass. A key advantage is that they do not conduct electricity, heat, or cold.

Because they contain no metal, these boots are ideal for security personnel who must frequently pass through metal detectors.

Matching Features to Your Environment

Beyond toe protection, specialized features adapt the boot to the unique hazards of a specific post.

Insulated Boots for Cold Conditions

For guards working outdoors in cold climates or inside refrigerated facilities, insulated boots are essential. They are designed with materials that trap air to keep feet warm and prevent frostbite.

Waterproof Boots for Wet Environments

Waterproof boots use membranes and sealed seams to keep your feet dry from rain, snow, or puddles. This is a critical feature for any outdoor post to ensure comfort and prevent health issues.

Electric Hazard (EH) Rated Boots

EH-rated boots are designed with non-conductive soles and heels that can protect you from accidental contact with live electrical circuits. This is a crucial safety standard for guards working near active power sources or on industrial sites.

The Critical Role of the Sole

The sole of your boot dictates its grip, durability, and comfort level for long hours of standing or patrolling.

Polyurethane (PU) Soles

PU soles are known for being lightweight and highly resistant to wear and tear. They offer a good balance of durability and comfort for varied duties.

EVA (Ethylene Vinyl Acetate) Midsoles

EVA is a foam-like material prized for its excellent shock absorption. Boots with EVA midsoles feel more athletic and are exceptionally comfortable for guards who spend a lot of time walking on hard surfaces like concrete.

Rubber Soles

Rubber is the go-to material for superior slip resistance, flexibility, and waterproofing. It is an excellent all-around choice for outdoor or unpredictable environments.

Understanding the Trade-offs

Choosing the right boot involves balancing competing factors. What you gain in one area, you might sacrifice in another.

Protection vs. Weight

A steel toe offers maximum, time-tested protection but adds significant weight, which can lead to fatigue. Alloy and composite toes provide certified protection at a much lower weight, making them better for active patrols.

Durability vs. Immediate Comfort

Rugged boots with thick rubber soles and leather uppers are extremely durable but may require a "break-in" period. In contrast, athletic-style safety shoes with EVA midsoles are comfortable immediately but may not withstand the same level of abuse.

The Necessity of Certified Standards

A boot labeled "safety toe" is meaningless without certification. Look for boots that meet ASTM (American Society for Testing and Materials) or CE (European Conformity) standards. These marks guarantee the boot has been rigorously tested to protect against specific, defined hazards.

Making the Right Choice for Your Post

Select your footwear based on the most likely challenges you will face on the job.

- If your primary focus is indoor patrols with long hours of standing: Prioritize a lightweight composite toe boot with a shock-absorbing EVA midsole for all-day comfort.

- If your primary focus is outdoor or industrial sites: Choose a waterproof boot with a steel or alloy toe and a durable, slip-resistant rubber sole.

- If you work in cold climates or pass through metal detectors: An insulated composite toe boot is the most practical and comfortable choice for your environment.

Ultimately, a well-chosen safety boot is a professional tool that directly enhances your safety, comfort, and effectiveness on duty.

Summary Table:

| Feature | Key Benefit | Ideal For |

|---|---|---|

| Steel Toe | Maximum impact resistance | Heavy-duty industrial sites |

| Alloy Toe | Lighter weight, same protection | Long patrols, reduced fatigue |

| Composite Toe | Non-metallic, passes metal detectors | Airports, secure facilities |

| Waterproof | Keeps feet dry in wet conditions | Outdoor posts, rainy climates |

| EH-Rated | Protection from electrical hazards | Industrial sites, live circuits |

| EVA Midsole | Superior shock absorption | Long hours on hard surfaces |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We specialize in crafting the exact safety boots your security teams need—from steel and composite toe options to waterproof and EH-rated designs. Our production capabilities ensure durable, certified protection tailored to any work environment. Enhance your team's safety and comfort with boots built for the job. Contact us today for a custom quote!

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the functions of the insole in safety shoes? Essential for Stability, Comfort & Protection

- What role do integrated force plates play in the performance testing of safety footwear? Biomechanical Analysis Experts

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- How does increasing carbon fiber content impact protective footwear insoles? Optimize Performance and Support

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- How does the weight of composite toe boots compare to steel toe boots? Lighter, Safer, More Comfortable

- How do surface patterns on rubber outsoles improve safety shoe performance? Master Traction with Advanced Engineering

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability