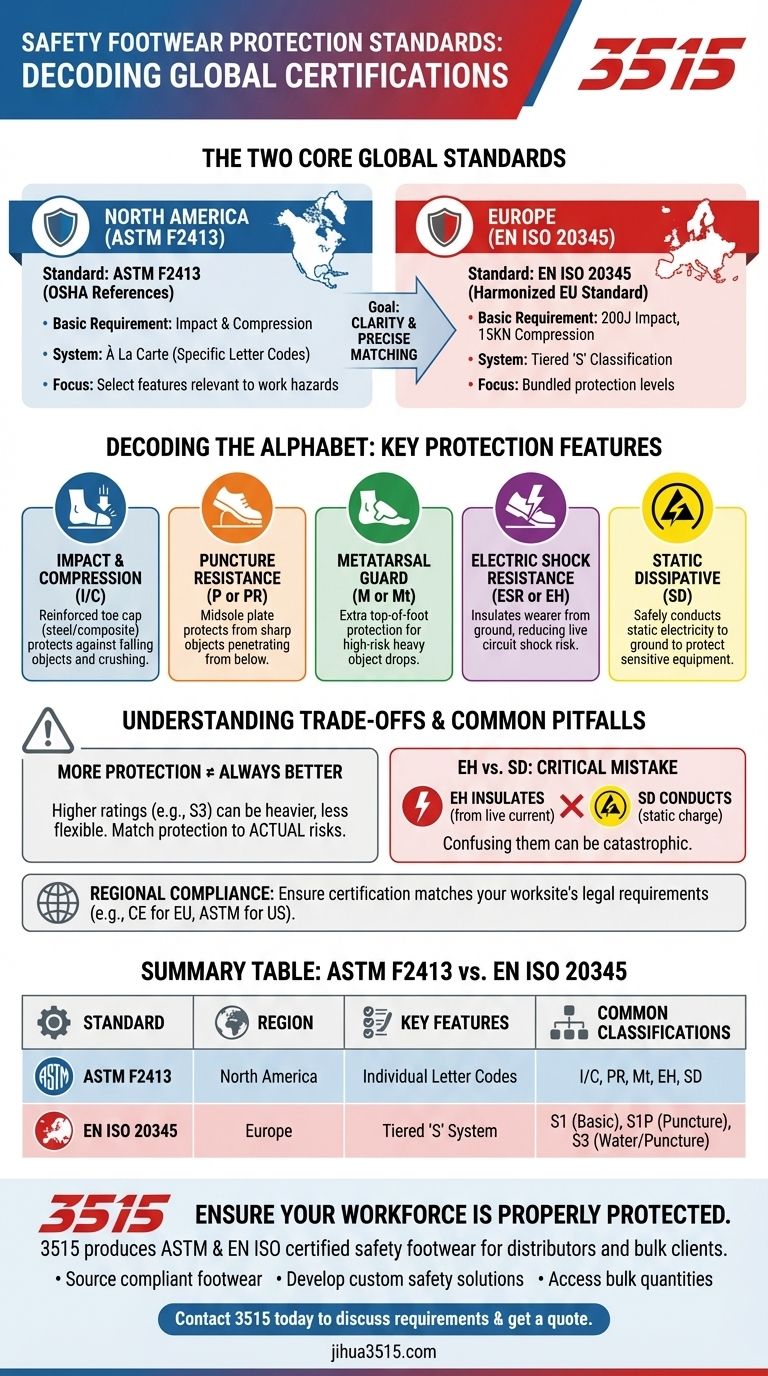

At its core, safety footwear protection is governed by two primary international standards: ASTM F2413 for North America and EN ISO 20345 for Europe. These standards provide a universal language for classifying footwear based on its ability to protect against specific workplace hazards, such as impact, compression, puncture, and electrical shock. Each standard uses a system of codes and ratings to clearly communicate the protective features built into a piece of footwear.

The goal of safety footwear standards is not just compliance, but clarity. They exist to help you precisely match the protective features of a boot to the specific, known risks of your job, ensuring the right tool is used for the right environment.

The Two Core Global Standards

While many countries have local regulations, most are based on one of two main frameworks. Understanding which standard applies to your region is the first step in selecting compliant and safe footwear.

The North American Standard (ASTM F2413)

In the United States, the Occupational Safety and Health Administration (OSHA) references the standards set by ASTM International. The key standard is ASTM F2413.

This standard establishes minimum performance requirements for footwear to protect against a variety of workplace dangers. Any footwear conforming to this standard must first meet the basic requirements for impact and compression resistance for the toe area.

Additional protections are identified on the label with specific letter codes, allowing users to select features relevant to their work.

The European Standard (EN ISO 20345)

The EN ISO 20345 standard is the harmonized European standard for safety footwear. All safety footwear in Europe must be certified and marked according to this standard.

The foundational requirement is a protective toe cap that can withstand a 200-joule impact and a 15 KN compression force.

Unlike the ASTM standard's à la carte approach, the EN standard uses a simpler, tiered "S" classification system that bundles protections together.

Decoding the Alphabet: Key Protection Features

Regardless of the standard, the types of protection offered are similar. These codes are typically found on a label sewn into the shoe's tongue.

Impact & Compression (I/C)

This is the most fundamental feature of safety footwear. It refers to a reinforced toe cap, traditionally made of steel or lighter composite materials, that protects the foot from falling objects and crushing forces.

Puncture Resistance (P or PR)

A puncture-resistant plate is positioned in the midsole to protect the foot from sharp objects penetrating from below, such as nails, glass, or metal shards. This is critical in construction and waste management environments.

Metatarsal Guard (M or Mt)

This feature provides an extra layer of protection for the metatarsal bones on the top of the foot. It is essential for industrial jobs where the risk of heavy objects dropping is high.

Electric Shock Resistance (ESR or EH)

Often marked as EH, this footwear is designed to insulate the wearer from the ground, reducing the risk of electric shock when accidentally stepping on a live electrical circuit.

Static Dissipative (SD)

SD footwear is engineered to safely conduct static electricity from the body to the ground in a controlled manner. This prevents a static spark that could damage sensitive electronic equipment or ignite flammable materials.

Understanding the Trade-offs and Common Pitfalls

Choosing the right footwear requires more than just reading a label; it requires understanding the context and potential for error.

More Protection Isn't Always Better

A boot with an S3 rating (the highest general EN rating) offers comprehensive protection but may be heavier, less flexible, and less breathable than a simpler S1 boot. The goal is to match the protection to the actual daily risks, not to over-spec and cause unnecessary fatigue or discomfort.

Confusing Electric Shock Resistance (EH) with Static Dissipative (SD)

This is a critical and potentially dangerous mistake. EH footwear insulates you, protecting you from a live current. SD footwear conducts static charge, grounding you to protect sensitive equipment. Using one where the other is required can have catastrophic consequences.

Ignoring Regional Compliance

A boot marked with CE (Conformité Européenne) meets the EN ISO 20345 standard but may not be recognized as compliant on an OSHA-regulated worksite in the US. Always ensure the footwear's certification matches the legal requirements of your specific location.

Making the Right Choice for Your Workplace

Your selection should be based on a thorough risk assessment of your environment.

- If your primary focus is working in North America: Look for the ASTM F2413 label and match the specific letter codes (EH, PR, Mt, SD) to your job's hazards.

- If your primary focus is working in Europe: Identify your required "S" rating (e.g., S1P or S3 for construction) based on your site's puncture and water-resistance needs.

- If your primary focus is handling sensitive electronics: Prioritize footwear specifically marked as Static Dissipative (SD) to prevent component damage.

- If your primary focus is working near live electrical hazards: Footwear rated for Electric Shock Resistance (EH or ESR) is an essential, non-negotiable safety measure.

Ultimately, understanding these standards empowers you to move beyond simple compliance and make an active, informed choice for your personal safety.

Summary Table:

| Standard | Region | Key Features | Common Classifications |

|---|---|---|---|

| ASTM F2413 | North America | Individual letter codes for specific hazards | I/C (Impact/Compression), PR (Puncture), Mt (Metatarsal), EH (Electrical Hazard), SD (Static Dissipative) |

| EN ISO 20345 | Europe | Tiered 'S' classification system | S1 (Basic), S1P (Puncture), S3 (Water/Puncture Resistant) |

Ensure Your Workforce is Properly Protected

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and EN ISO certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the right protection for your specific workplace hazards.

Let us help you:

- Source compliant footwear for your target market.

- Develop custom safety solutions tailored to your clients' needs.

- Access bulk quantities with consistent quality and reliable delivery.

Contact 3515 today to discuss your safety footwear requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What role does an industrial-grade heat setting oven play in the bonding of the safety shoe upper and sole?

- What specific requirements are necessary for machinery used in the production of high-performance safety shoes?

- What is the function of the ergonomic curve design in professional nursing safety shoes? Enhance Comfort & Foot Health

- How do integrated sensing devices within safety shoes contribute to product lifecycle management? Boost Safety & ROI

- What should be avoided when buying security guard safety boots? Protect Your Team from Costly Mistakes

- In what way do assistive devices like crutches and protective footwear synergize during early-stage load management?

- What is the role of high-definition USB cameras in the detection of safety shoes? Enhancing Site Safety with HD Clarity

- In what ways does sensor integration technology enhance safety shoes? Revolutionize Worker Protection with Active Data