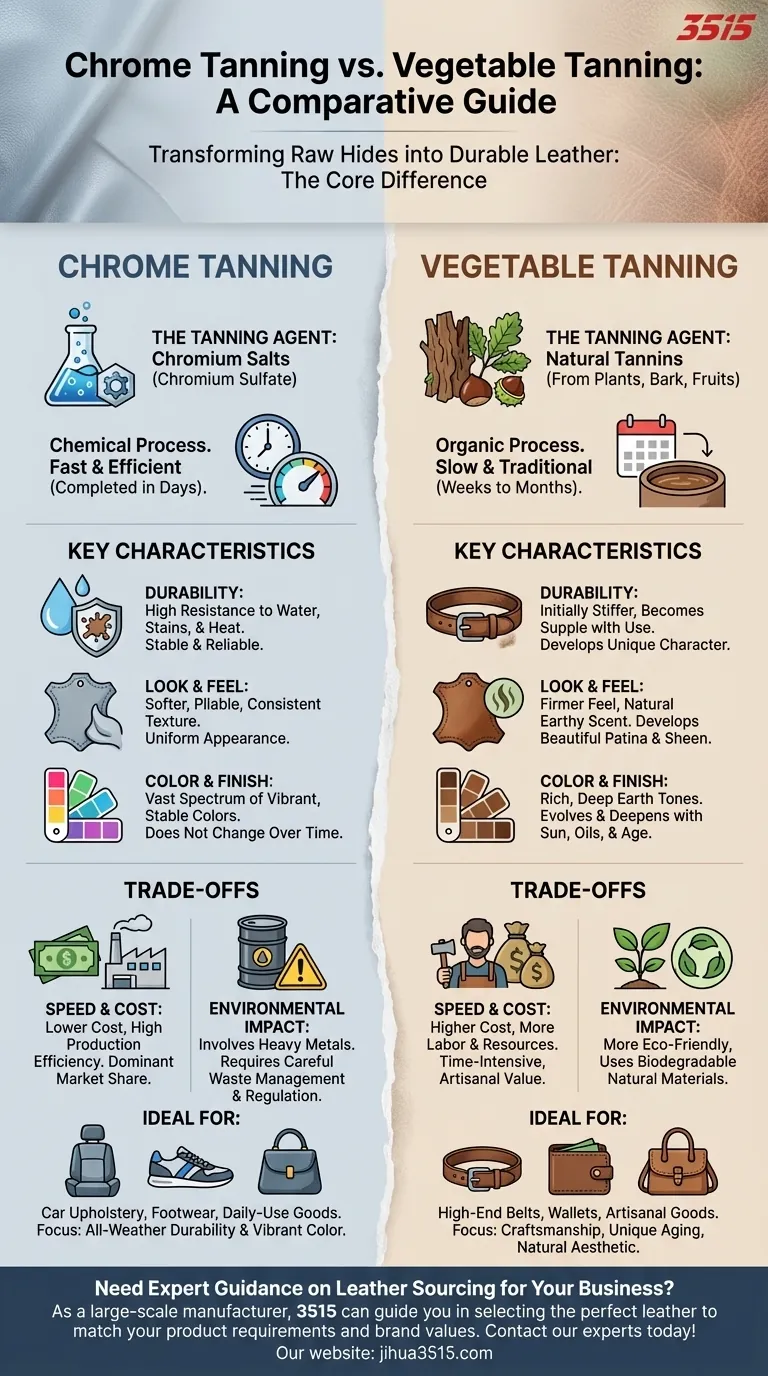

At its core, the difference between chrome tanning and vegetable tanning lies in the agent used to transform raw animal hide into durable leather. Chrome tanning uses chromium salts for a fast, modern process, while vegetable tanning uses natural tannins from plants for a slow, traditional method. This fundamental choice dictates the leather's final look, feel, durability, and environmental impact.

The decision between chrome-tanned and vegetable-tanned leather is a choice between industrial efficiency and consistent performance (chrome) versus artisanal tradition and unique character that evolves over time (vegetable).

The Tanning Agent: Chemical vs. Natural

The tanning agent is the single most important factor in the leather-making process. It determines the speed of production and the inherent qualities of the final material.

Chrome Tanning: The Modern Standard

Chrome tanning utilizes a solution of chromium salts, specifically chromium sulfate. This chemical process is incredibly efficient, often completed in just a few days.

Because of its speed and the resulting material's properties, chrome tanning accounts for the vast majority of leather produced worldwide.

Vegetable Tanning: The Artisanal Tradition

Vegetable tanning relies on tannins, which are naturally occurring compounds found in organic matter like tree bark, leaves, and fruits.

This process is slow and requires significant skill, with hides soaked in tanning solutions for weeks or even months. It is the oldest method of tanning known.

Comparing the Final Product: Key Characteristics

The tanning method directly imparts distinct and predictable characteristics to the leather.

Durability and Resistance

Chrome-tanned leather is known for its exceptional resistance to water, stains, and heat right out of the tannery. It offers a stable and reliable durability suitable for products exposed to all weather conditions.

Vegetable-tanned leather is initially stiffer but becomes more supple with use. While very durable for applications like shoe soles, it is more susceptible to water damage and staining if not properly cared for.

Look and Feel

Leather from chrome tanning is often softer and more pliable from the start. The process produces a consistent product where each hide feels and looks very similar.

Vegetable-tanned leather has a distinctively natural, earthy scent and a firmer feel. Over time, it develops a beautiful patina—a unique sheen and darkening that reflects its use and history. No two vegetable-tanned products age exactly the same.

Color and Finish

The chrome tanning process allows for a vast and vibrant spectrum of colors that remain consistent and stable over the product's life.

Vegetable tanning typically produces rich, deep tones of brown, beige, and tan. The color is known to evolve and deepen with exposure to sun and oils from your hands.

Understanding the Trade-offs

Neither method is universally superior; they represent a series of trade-offs in speed, cost, and environmental responsibility.

Speed and Cost

The efficiency of chrome tanning makes it significantly faster and less expensive to produce. This is the primary reason for its dominance in the market.

The time-intensive nature of vegetable tanning requires more labor and resources, making the final product more costly.

Environmental Considerations

Vegetable tanning is widely regarded as the more environmentally friendly option, as it uses biodegradable, natural materials.

Chrome tanning involves heavy metals. While modern tanneries operate under strict regulations to treat wastewater and manage chromium, the potential for environmental contamination exists if these processes are not handled correctly.

Making the Right Choice for Your Needs

Selecting the right leather depends entirely on the intended use and desired aesthetic of the final product.

- If your primary focus is all-weather durability and vibrant, stable color: Chrome-tanned leather is the ideal choice for items like car upholstery, footwear, and daily-use handbags.

- If your primary focus is craftsmanship, unique aging, and a natural aesthetic: Vegetable-tanned leather is perfect for high-end belts, wallets, and artisanal goods where the story of the material is part of its value.

Understanding these core differences empowers you to select not just a material, but the right character for your product.

Summary Table:

| Characteristic | Chrome Tanning | Vegetable Tanning |

|---|---|---|

| Tanning Agent | Chromium Salts | Natural Tannins (Plants) |

| Process Speed | Fast (Days) | Slow (Weeks/Months) |

| Durability | High water & heat resistance | Durable, develops patina |

| Aesthetic | Consistent, vibrant colors | Natural, ages uniquely |

| Cost | Lower | Higher |

| Environmental Impact | Requires careful waste management | More eco-friendly, biodegradable |

Need Expert Guidance on Leather Sourcing for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we can guide you in selecting the perfect leather—whether chrome-tanned for durability or vegetable-tanned for its unique character—to match your product's requirements and brand values.

Let's discuss your next project. Contact our experts today to get started!

Visual Guide

Related Products

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Moc Toe Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- How does pull-up leather behave in shoes? It develops a unique, evolving patina.

- What are the benefits of seamless leather in office work shoes? Eliminate Friction for All-Day Comfort

- What should consumers look for to avoid misleading claims about leather quality? A Guide to Identifying Genuine Quality

- What should be known about genuine leather for shoes? Don't Be Misled by the Label

- How can crocodile-inspired leather dress shoes make a statement at formal events? Command Attention with Bold Style