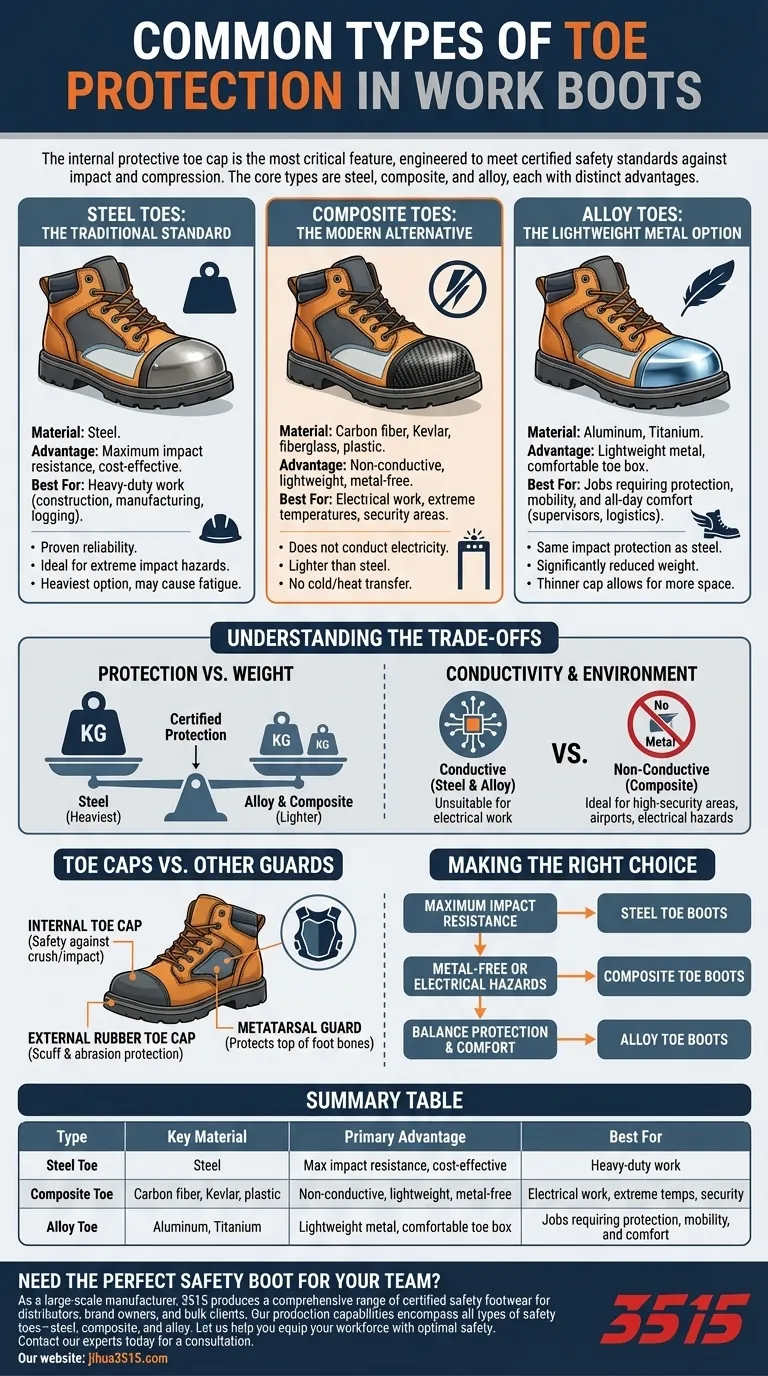

When selecting safety footwear, the internal protective toe cap is the most critical feature. The common types are steel, composite, and alloy, each engineered from different materials to provide certified protection against impact and compression, but with distinct properties that suit different work environments.

The core decision in choosing a safety toe is not about which is "strongest"—all must meet the same safety standards. The real choice is a trade-off between the specific advantages of each material: the raw strength of steel, the non-conductive and lightweight nature of composite, and the balanced performance of alloy.

The Core Safety Toe Materials Explained

Understanding the fundamental differences between each material is key to selecting a boot that works for you, not against you. Each type is designed to meet specific workplace demands.

Steel Toes: The Traditional Standard

Steel is the original material for safety toes and remains the benchmark for heavy-duty protection. It is a proven, reliable, and often the most cost-effective option.

These caps are ideal for environments with extreme impact hazards, such as construction sites, manufacturing plants, and logging operations where the risk of heavy falling objects is highest.

Composite Toes: The Modern Alternative

Composite toes are a newer innovation, crafted from non-metallic materials like carbon fiber, Kevlar, fiberglass, or dense plastic. Their primary advantage is being completely metal-free.

Because they do not conduct electricity, they are the essential choice for electricians and engineers. They are also lighter than steel and do not transfer cold or heat, making them more comfortable in extreme temperatures.

Alloy Toes: The Lightweight Metal Option

Alloy toes provide a middle ground, using lightweight metals such as aluminum or titanium. They deliver the same level of impact protection as steel but at a significantly reduced weight.

These caps can be made thinner than steel, often resulting in a more spacious and comfortable toe box. They are an excellent choice for workers who need robust protection but also value mobility and comfort, like supervisors or logistics personnel.

Understanding the Trade-offs

Choosing the right toe protection involves more than just meeting a safety requirement. It's about optimizing for your specific daily tasks and potential hazards.

Protection vs. Weight

While all certified safety toes protect against the same level of impact, their weight differs significantly. Steel is the heaviest, which can lead to fatigue over a long shift.

Alloy and composite options dramatically reduce the boot's weight, enhancing comfort and reducing strain without compromising on the required safety rating.

Conductivity and Environment

The material of your toe cap has critical implications for your work environment. Steel and alloy are conductive, making them unsuitable for work around live electrical circuits.

Composite toes are non-conductive and will not set off metal detectors, making them ideal for high-security areas, airports, and any job with electrical hazards.

Toe Caps vs. Other Guards

It's important to distinguish the internal safety toe from other protective features. An external rubber toe cap is simply an outer layer of material that prevents scuffs and abrasion to the boot itself.

A metatarsal guard is a separate piece of armor that rests on top of the boot's laces to protect the delicate metatarsal bones on the top of your foot from crushing injuries.

Making the Right Choice for Your Job

Your final decision should be guided by the unique demands of your profession.

- If your primary focus is maximum impact resistance and cost-effectiveness: Steel toe boots remain the industry standard for heavy-duty work like construction or heavy manufacturing.

- If your primary focus is working in a metal-free environment or with electrical hazards: Composite toe boots are the essential choice for safety, compliance, and comfort in extreme temperatures.

- If your primary focus is balancing strong protection with all-day comfort and mobility: Alloy toe boots offer a premium, lightweight alternative to traditional steel without sacrificing strength.

Ultimately, understanding these material differences empowers you to select footwear that protects you effectively without hindering your performance.

Summary Table:

| Type | Key Material | Primary Advantage | Best For |

|---|---|---|---|

| Steel Toe | Steel | Maximum impact resistance, cost-effective | Heavy-duty work (construction, manufacturing) |

| Composite Toe | Carbon fiber, Kevlar, plastic | Non-conductive, lightweight, metal-free | Electrical work, extreme temperatures, security areas |

| Alloy Toe | Aluminum, Titanium | Lightweight metal, comfortable toe box | Jobs requiring protection, mobility, and all-day comfort |

Need the Perfect Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety toes—steel, composite, and alloy—ensuring you get the right protection, comfort, and durability for your specific industry needs.

Let us help you equip your workforce with optimal safety.

Contact our experts today for a consultation

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the advantages of leather uppers in work boots? Unmatched Durability & Protection

- Who are Yard boots ideal for? The Ultimate Guide for Outdoor and Work Enthusiasts

- What are the common workplace hazards that can be mitigated with the right work boots? Protect Your Workforce

- What health problems can result from wearing ill-fitting work boots? Protect Your Body from Foot to Back

- Why is slip resistance a necessary feature in work boots? Prevent Falls and Ensure Workplace Safety

- What factors should be considered when choosing between pull-on and lace-up work boots? A Guide to Safety & Comfort

- What role does grip and traction play in farming and gardening boots? Ensure Safety and Stability on Any Terrain

- What are the advantages of soft-toe boots? Superior comfort and flexibility for low-hazard work.