To be clear, the three common safety toe options in military boots are Steel Toe, Composite Toe, and Soft Toe. Steel offers the highest level of protection against impact and compression, while composite provides a lighter-weight, non-metallic alternative. Soft toe boots offer no impact protection and are chosen purely for comfort and mobility where no such hazards exist.

The choice between safety toe types is not about finding the "best" boot, but about understanding a fundamental trade-off. You are balancing the absolute necessity of hazard protection against the operational demands of weight, agility, and environmental conditions.

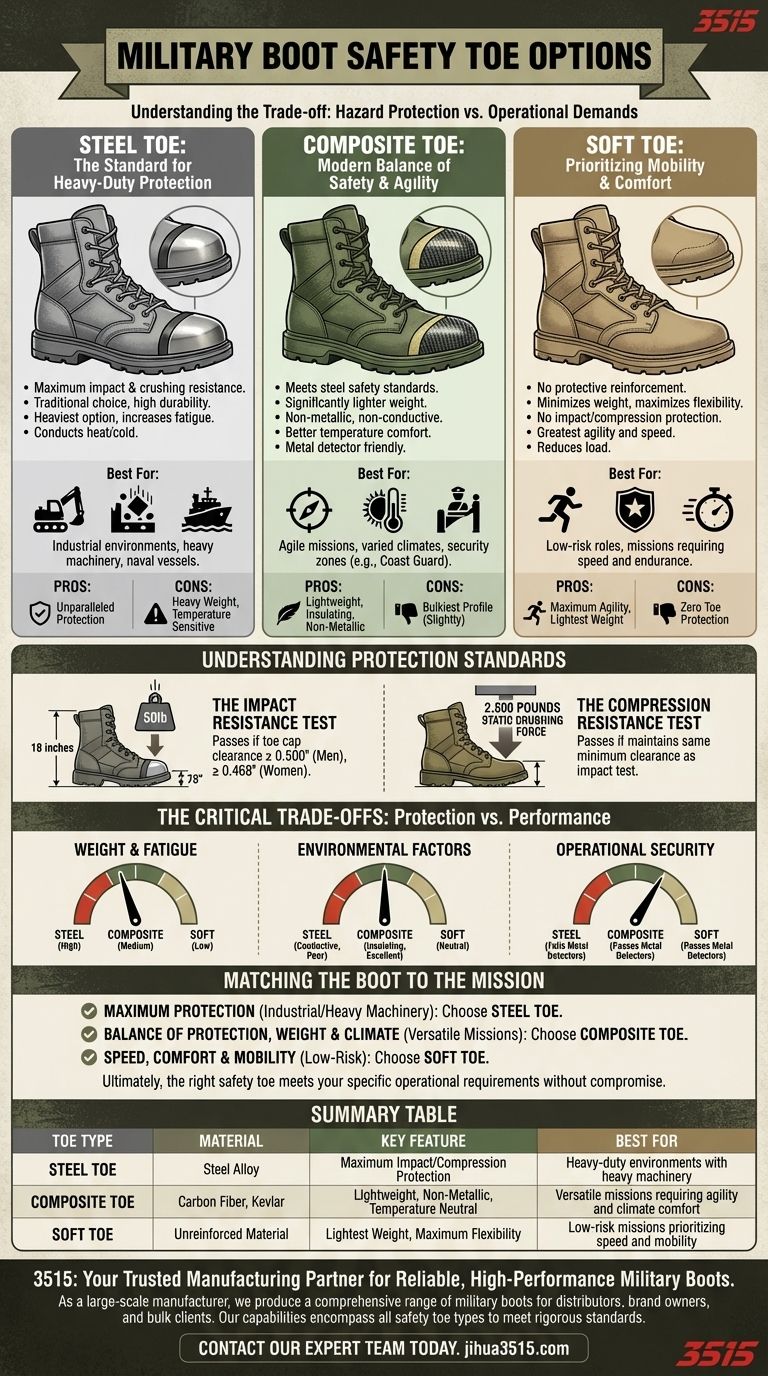

Deconstructing the Core Options

Each toe type is designed for a specific operational context. Understanding their material properties and intended use is the first step in making an informed decision.

Steel Toe: The Standard for Heavy-Duty Protection

A steel toe cap is the traditional choice for maximum safety. It provides unparalleled resistance to crushing and impact forces.

This is why they are a common requirement in environments with heavy machinery or falling objects, such as on the deck of a naval vessel. The primary drawback is their weight, which can increase fatigue over long periods.

Composite Toe: The Modern Balance of Safety and Agility

Composite toes are made from non-metallic materials like carbon fiber, Kevlar, or specialized plastics. They meet the same impact and compression resistance standards as steel toes.

Their key advantage is significantly lower weight. They also do not conduct heat or cold, making them more comfortable in extreme temperatures, and will not set off metal detectors. This has made them a popular choice for certain branches, including the Coast Guard.

Soft Toe: Prioritizing Mobility and Comfort

A soft toe boot contains no protective reinforcement in the toe box. Its design is entirely focused on minimizing weight and maximizing flexibility.

These boots are suitable for roles where there is a low or non-existent risk of foot impact injuries. They allow for greater agility and reduce the overall load on the service member, which is critical for missions requiring speed and endurance.

Understanding the Protection Standards

When a boot is "safety rated," it means it has passed specific, measurable tests for protection. These standards ensure the boot performs predictably under stress.

The Impact Resistance Test

Certified safety footwear must protect the wearer from a significant impact. The standard test involves dropping a 50-pound weight from a height of about 18 inches, creating a 75 foot-pound impact.

The boot passes if the toe cap maintains a minimum clearance of 0.500 inches for men's footwear and 0.468 inches for women's after the impact.

The Compression Resistance Test

This test measures the toe cap's ability to withstand a static crushing force. A force of 2,500 pounds is slowly applied to the toe.

To pass, the boot must maintain the same minimum clearance inside the toe cap as required by the impact test. This ensures the wearer's toes are not crushed under a heavy, stationary object.

The Critical Trade-offs: Protection vs. Performance

Choosing the right toe type involves weighing the level of protection you need against the performance you demand from your footwear.

Weight and Fatigue

This is the most noticeable difference. A steel toe is the heaviest, which can lead to greater fatigue during long marches or shifts. A composite toe offers the same protection for less weight, while a soft toe is by far the lightest.

Environmental Factors

Steel is an excellent thermal conductor. In cold environments, a steel toe can become dangerously cold, while in extreme heat, it can retain warmth. Composite materials are poor conductors, providing superior insulation and comfort in a wider range of temperatures.

Operational Security

Because composite toes are non-metallic, they are the clear choice for personnel who must frequently pass through metal detectors or work around sensitive electronic equipment.

Matching the Boot to the Mission

Your choice should be dictated entirely by your operational environment and the known hazards you will face.

- If your primary focus is maximum protection in an industrial or heavy machinery environment: Steel toe is the definitive choice for its proven, heavy-duty impact resistance.

- If your primary focus is a balance of certified protection, reduced weight, and performance in varied climates: Composite toe offers the most versatile and modern solution.

- If your primary focus is speed, comfort, and mobility where impact hazards are not a concern: Soft toe provides the necessary performance without the burden of a safety cap.

Ultimately, the right safety toe is the one that meets your specific operational requirements without compromise.

Summary Table:

| Toe Type | Material | Key Feature | Best For |

|---|---|---|---|

| Steel Toe | Steel Alloy | Maximum Impact/Compression Protection | Heavy-duty environments with heavy machinery |

| Composite Toe | Carbon Fiber, Kevlar | Lightweight, Non-Metallic, Temperature Neutral | Versatile missions requiring agility and climate comfort |

| Soft Toe | Unreinforced Material | Lightest Weight, Maximum Flexibility | Low-risk missions prioritizing speed and mobility |

As a large-scale manufacturer, 3515 produces a comprehensive range of military boots for distributors, brand owners, and bulk clients.

We understand that the right safety toe is critical for operational success. Our production capabilities encompass all types of safety toe footwear, engineered to meet rigorous standards without compromising on performance.

Let us help you equip your personnel with the optimal footwear for their specific mission requirements.

Contact our expert team today to discuss your needs and discover how 3515 can be your trusted manufacturing partner for reliable, high-performance military boots.

Visual Guide

Related Products

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- Why is conditioning the leather of military boots important? Essential for Durability & Performance

- What is the benefit of synthetic military boots? Superior Mobility & Quick-Drying Performance

- What is the function of the steel shank in jungle boots? Unlock Maximum Support & Protection

- What maintenance practices extend the lifespan of combat boots? A Proactive Care Guide for Peak Performance

- What are some real-world applications of military camouflage boots? From Tactical to Trendsetting

- What are some alternatives to combat boots? Find the Perfect Footwear for Your Needs

- What reduction in heat strain could be achieved with a 10% metabolic savings from super boots?

- What is the historical background of combat boots and jump boots? Discover Their Purpose-Built Evolution