At their core, safety boots are a critical form of personal protective equipment (PPE) designed to shield workers from a wide range of environmental and physical dangers. They protect against hazards including direct impact from falling objects, punctures from sharp materials on the ground, electrical shocks, chemical spills, slippery surfaces, and extreme temperatures.

The most significant mistake is assuming any safety boot will suffice. True safety comes from methodically matching the specific protective features of the boot—such as steel toes, puncture-resistant soles, or electrical hazard ratings—to the precise risks present in your work environment.

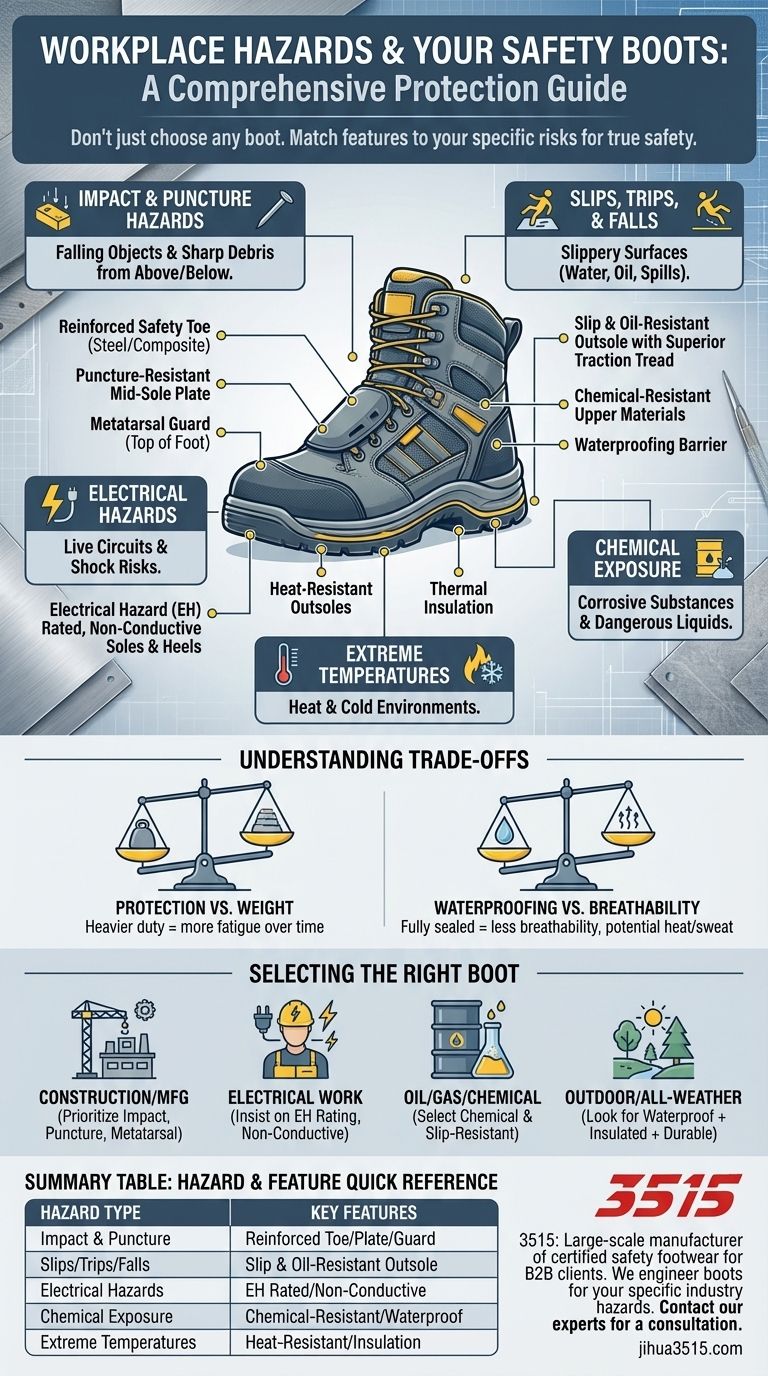

A Systematic Breakdown of Workplace Hazards

Understanding the dangers is the first step to selecting the right protection. Workplace hazards can be broadly categorized, with specific boot features engineered to counteract each one.

Impact and Puncture Hazards

This is the most classic and widely understood function of a safety boot. It covers dangers from above and below.

Protection is primarily provided by a reinforced safety toe, often made of steel or lighter composite materials, which shields the foot from falling or rolling heavy equipment and materials.

To guard against sharp objects on the ground like nails, screws, or metal shards, boots feature a penetration-resistant plate in the mid-sole.

For added protection, some boots include a metatarsal guard that covers the top of the foot, an area left vulnerable by a standard safety toe.

Slips, Trips, and Falls

Slippery surfaces are a leading cause of workplace injuries. These conditions can be caused by water, oil, chemicals, or other spills.

Safety boots address this with specially designed slip-resistant outsoles. The material composition and tread pattern are engineered to provide superior traction and grip on slick ground.

Oil-resistant soles are crucial in environments with petrol or chemical spills, as they prevent the rubber from degrading and losing its effectiveness.

Electrical Hazards

In environments with live electrical circuits, the risk of accidental contact and severe shock is a major concern.

Boots with an Electrical Hazard (EH) rating are constructed with non-conductive soles and heels. This design helps to insulate the wearer from the ground, minimizing the chance of completing an electrical circuit.

It is critical to note that this protection is secondary and can be compromised by excessive wear or wet conditions.

Chemical and Contaminant Exposure

Many industrial sites involve work with corrosive or hazardous substances that can cause severe burns or injury upon contact.

Boots designed for these environments use chemical-resistant materials for the upper and outsole. This prevents dangerous substances like acids, oils, and other chemicals from penetrating the boot and reaching the skin.

Waterproofing is also a key feature, not only for comfort in wet conditions but also to protect against dangerous liquid contaminants.

Extreme Temperatures and Environments

Working in extreme heat or cold presents its own set of challenges, from burns to frostbite, as well as general fatigue.

For high-temperature environments, boots may feature heat-resistant outsoles that will not melt or deform on hot surfaces.

In cold weather, insulated boots provide a thermal barrier to keep feet warm and prevent cold-related injuries.

Understanding the Trade-offs

Selecting a safety boot is not about finding one with the most features. It's about finding the one with the right features, as every protective element comes with a trade-off.

Protection vs. Weight

Heavier-duty protection, such as steel toes and thick, penetration-resistant soles, adds significant weight to the boot. Over a long shift, this can lead to increased fatigue.

Waterproofing vs. Breathability

A fully waterproof boot is excellent for wet environments but can trap sweat and heat, leading to discomfort in hot or dry conditions. A more breathable boot may be better for comfort but offers less protection from liquids.

The "One Boot Fits All" Myth

A boot with an EH rating for an electrician is built differently than one with chemical resistance for a plant worker. Using the wrong boot for the job can provide a false sense of security and may not offer the necessary protection.

Selecting the Right Boot for Your Environment

Your choice must be driven by a clear assessment of your primary risks.

- If your primary focus is construction or manufacturing: Prioritize boots with certified safety toes, metatarsal guards, and puncture-resistant soles to protect against impact and sharp debris.

- If your primary focus is electrical work: Insist on boots with a clear Electrical Hazard (EH) rating and non-conductive materials.

- If your primary focus is oil, gas, or chemical processing: Select boots specifically rated for chemical and oil resistance with superior slip-resistant outsoles.

- If your primary focus is outdoor or all-weather work: Look for a combination of waterproofing for rain and insulation for cold, along with durable outsoles for rough terrain.

Ultimately, choosing the right safety boot is an active, informed decision that directly contributes to your personal safety on the job.

Summary Table:

| Hazard Type | Key Protective Boot Features |

|---|---|

| Impact & Puncture | Reinforced Safety Toe (Steel/Composite), Penetration-Resistant Mid-Sole, Metatarsal Guard |

| Slips, Trips, Falls | Slip & Oil-Resistant Outsole |

| Electrical Hazards | Electrical Hazard (EH) Rated, Non-Conductive Materials |

| Chemical Exposure | Chemical-Resistant Upper/Outsole, Waterproofing |

| Extreme Temperatures | Heat-Resistant Soles, Insulation |

Don't compromise on workplace safety. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective boots and shoes, precisely engineered to mitigate the specific hazards in your industry—from impact and punctures to electrical and chemical risks.

Contact our experts today for a consultation. We'll help you select or customize the perfect safety footwear to protect your team and meet your business needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- How can you ensure consistent comfort in work boots? Focus on Fit, Materials & Ergonomics

- How should farm boots be cleaned? A Complete Guide to Preserve Your Investment

- What are firefighter station boots used for? Essential Footwear for Daily Station Comfort & Professionalism

- What features should HVAC technicians look for in work boots? Find the Perfect Blend of Safety & Comfort

- How does toe box design differ between men's and women's work boots? Fit for a Woman's Foot Anatomy

- What are the pros of Goodyear Welt Construction? Unmatched Durability & Resoleability

- Which brands are known for high-quality work boots? A Guide to Durable, Safe Footwear

- What are some user experiences with full leather boots? Unmatched Durability & Long-Term Value