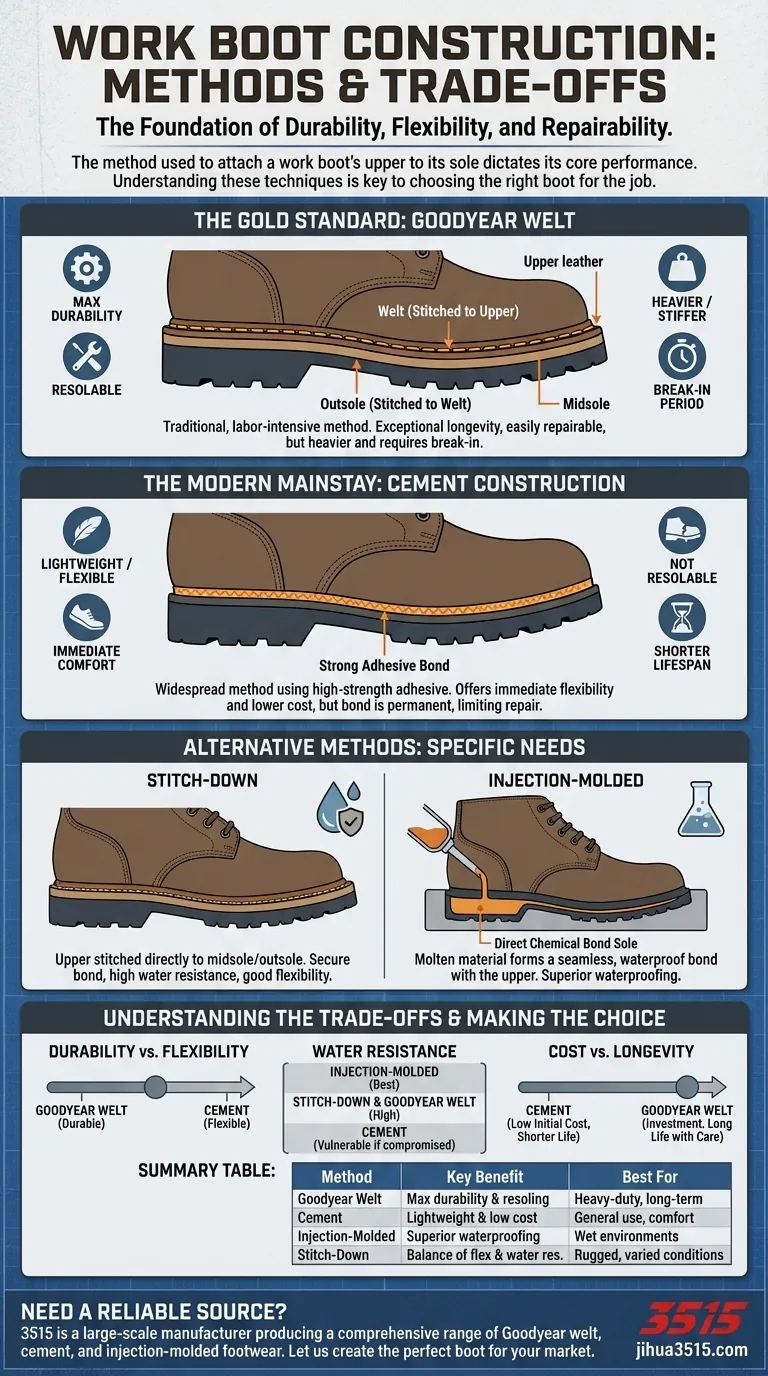

The most common construction methods for work boots are Goodyear Welt, Cement, Stitch-down, and Injection-Molded. The technique used to attach the boot's upper to its sole is the single most important factor determining its durability, water resistance, flexibility, and whether it can be repaired.

Understanding how a work boot is built is more important than almost any other feature. The construction method dictates the boot's fundamental trade-off between long-term durability and out-of-the-box flexibility.

The Gold Standard: Goodyear Welt Construction

The Goodyear welt is a traditional, labor-intensive method prized for its exceptional durability and longevity. It is the hallmark of high-quality, heavy-duty work boots.

How It's Made

A strip of leather, rubber, or plastic—the welt—is first stitched to the boot's upper. A separate stitch then attaches this welt to the outsole. This creates two independent seams, forming a strong, layered bond.

The Primary Benefit: Durability and Resoling

Because the outsole is stitched to the welt and not directly to the upper, a cobbler can easily remove the old sole and attach a new one without compromising the boot's structure. This makes Goodyear welted boots incredibly long-lasting and cost-effective over time.

The Inherent Downside

This robust construction creates a stiffer boot that requires a break-in period. The multiple layers also make it heavier and generally more expensive than other methods.

The Modern Mainstay: Cement Construction

Cement construction is the most widespread method used in modern footwear, from athletic shoes to work boots. It relies on a strong, flexible adhesive to bond the upper directly to the sole.

How It's Made

The process is straightforward: the sole is attached to the upper using a high-strength, waterproof adhesive. There is no stitching involved in the sole attachment.

The Primary Benefit: Flexibility and Lower Cost

This method produces a significantly lighter and more flexible boot right out of the box, with virtually no break-in period. The simpler manufacturing process also makes these boots more affordable.

The Resoling Challenge

While some specialized adhesives can be used to re-bond a sole, most cement-constructed boots are not designed to be resoled. The bond is meant to be permanent, and wear and tear on the sole typically signals the end of the boot's life.

Alternative Methods for Specific Needs

While Goodyear welt and cement construction dominate the market, other methods offer unique advantages for specific working conditions.

Stitch-down Construction

In this method, the leather upper is flanged outward and stitched directly to the midsole and outsole. This creates a very secure and flexible bond with a high degree of water resistance, as it reduces the number of seams water can penetrate.

Injection-Molded Construction

This technique involves placing the boot's upper on a mold, which is then injected with a molten material like PVC or polyurethane. This material forms a direct chemical bond with the upper as it cools and hardens, creating a seamless and completely waterproof connection between the sole and the boot.

Understanding the Trade-offs

Choosing the right construction method involves balancing competing priorities. There is no single "best" method; there is only the best method for your specific job and budget.

Durability vs. Flexibility

Goodyear welt construction is the undisputed leader in long-term durability and repairability. Cement construction offers superior flexibility and immediate comfort.

Water Resistance

Injection-molded boots offer the highest level of waterproofing due to their seamless design. Goodyear welt and stitch-down methods are highly water-resistant, while cement construction can be vulnerable if the adhesive bond is compromised.

Cost vs. Longevity

Cemented boots have a lower upfront cost but a shorter lifespan. Goodyear welted boots are a significant initial investment but can last for many years with proper care and resoling, offering better long-term value.

Making the Right Choice for Your Work

Your daily tasks and environment should dictate your choice.

- If your primary focus is maximum longevity and repairability for heavy-duty work: Choose a boot with Goodyear welt construction.

- If your primary focus is lightweight comfort, flexibility, and affordability: Cement construction is the most practical and widely available option.

- If your primary focus is superior waterproofing for consistently wet environments: Prioritize boots with an injection-molded construction.

- If your primary focus is a balance of flexibility and water resistance: Look for boots made with the stitch-down method.

Ultimately, the way a boot is put together defines its character and how it will perform for you on the job.

Summary Table:

| Construction Method | Key Benefit | Best For |

|---|---|---|

| Goodyear Welt | Maximum durability & resoling | Heavy-duty, long-term work |

| Cement | Lightweight flexibility & low cost | General use, immediate comfort |

| Injection-Molded | Superior, seamless waterproofing | Wet environments |

| Stitch-Down | Balance of flexibility & water resistance | Rugged, varied conditions |

Need a reliable source for all types of work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable Goodyear welted models, flexible cement constructions, and waterproof injection-molded boots.

Let us help you find or create the perfect boot for your market's needs. Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the essential features of fire boots? A Guide to Maximum Safety & Performance

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Why is brand reputation important when selecting farming and gardening boots? Invest in Durability & Comfort

- Are safety toe boots available in fashionable styles? Discover Modern, Stylish Work Boots

- What industries is this boot designed for? Ideal for Oil & Gas and Chemical Manufacturing

- What are the main reasons for the popularity of moc toe boots? Unmatched Comfort, Durability & Style

- How can proper care extend the lifespan of work boots? Maximize Durability & Safety

- What structural features are important in Wellington work boots? Ensure Slip-On Safety and Support