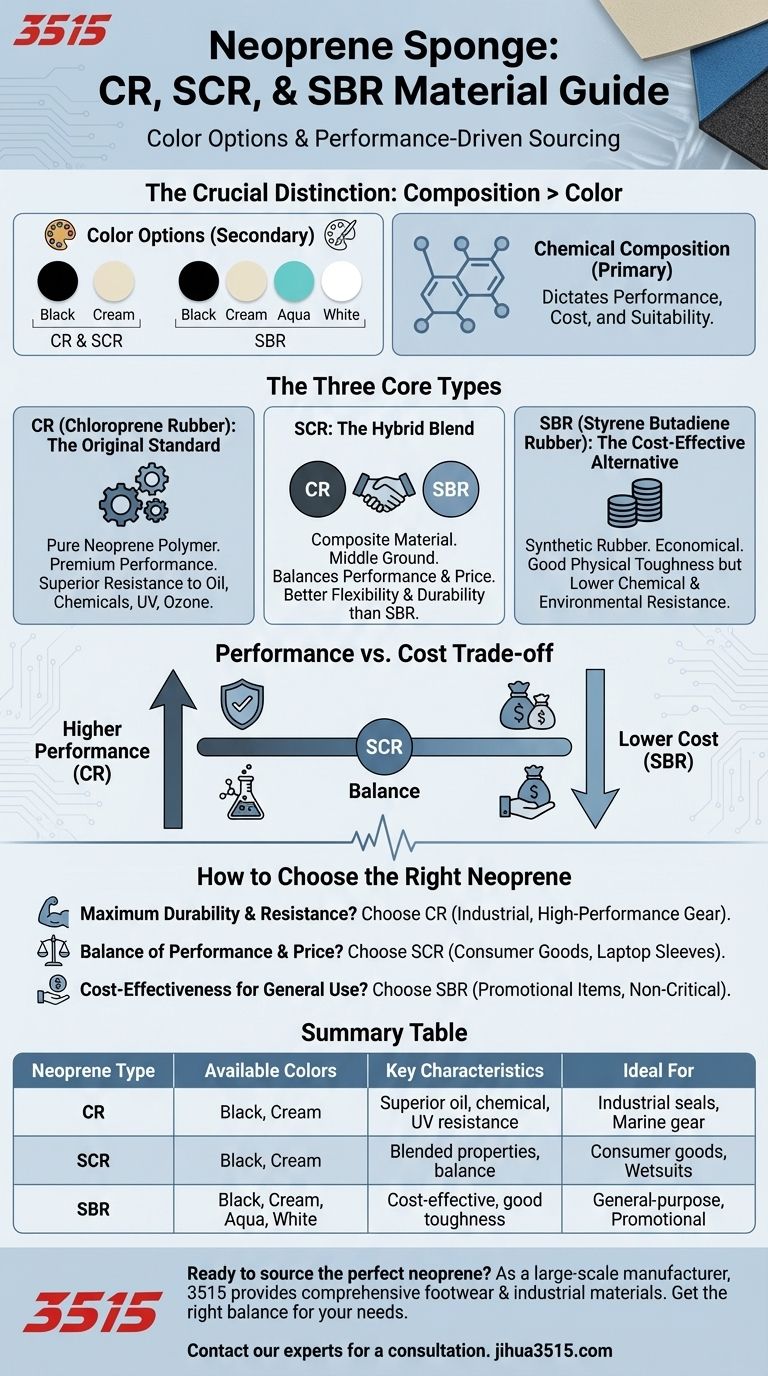

When selecting a neoprene sponge, the color options are directly tied to the specific type of rubber compound used. CR and SCR neoprene sponges are typically available in black and cream. SBR neoprene sponges offer a wider palette, available in black, cream, aqua, and white.

The crucial distinction between these neoprene types is not their color availability but their underlying chemical composition. This dictates performance, cost, and suitability for your specific application.

The Three Core Types of Neoprene Sponge

While often grouped under the general term "neoprene," CR, SCR, and SBR represent distinct materials with different capabilities. Understanding these differences is the key to a successful material choice.

CR (Chloroprene Rubber): The Original Standard

CR is the original, pure form of neoprene. It is a polymer of chloroprene and sets the benchmark for performance in this category. Its chemical structure gives it inherent resistance to a wide range of environmental factors.

SBR (Styrene Butadiene Rubber): The Cost-Effective Alternative

SBR is a different synthetic rubber that is often used as a more economical alternative to CR. While it shares some physical properties, its chemical resistance and durability are generally lower than that of pure CR.

SCR: The Hybrid Blend

SCR is a composite material made by blending CR and SBR sponges. This approach aims to provide a middle ground, offering some of the desirable properties of CR at a price point closer to SBR.

Understanding the Performance vs. Cost Trade-off

Your choice of neoprene should be driven by the demands of the final product, as the performance and cost vary significantly between these three types.

Why CR is the Premium Choice

Pure CR is specified for applications where failure is not an option. It provides superior resistance to oils, chemicals, UV degradation, and ozone. This makes it the ideal choice for industrial seals, gaskets, and high-performance marine applications.

The Strategic Role of SBR

SBR is an excellent material for general-purpose applications where cost is a primary driver. It offers good physical toughness and abrasion resistance but lacks the robust chemical and environmental resistance of CR.

Finding the Middle Ground with SCR

An SCR blend is a common choice for consumer goods. It provides better feel, flexibility, and durability than pure SBR, making it suitable for items like laptop sleeves, basic wetsuits, and promotional materials where you need a balance of quality and cost.

How to Choose the Right Neoprene for Your Application

Selecting the correct material goes far beyond color. Focus on the core requirements of your project to make an informed decision.

- If your primary focus is maximum durability and resistance: Choose CR for its pure chloroprene composition, ideal for industrial or high-performance gear.

- If your primary focus is cost-effectiveness for general use: Choose SBR, especially when chemical and oil resistance are not critical factors.

- If your primary focus is a balance of performance and price: Choose SCR for consumer products that require good flexibility without the premium cost of pure CR.

Understanding these material differences empowers you to select a neoprene based on true performance needs, not just surface-level options.

Summary Table:

| Neoprene Type | Available Colors | Key Characteristics | Ideal For |

|---|---|---|---|

| CR | Black, Cream | Superior oil, chemical, and UV resistance | Industrial seals, high-performance marine gear |

| SCR | Black, Cream | Blended properties, balance of performance and cost | Consumer goods, laptop sleeves, basic wetsuits |

| SBR | Black, Cream, Aqua, White | Cost-effective, good toughness, lower chemical resistance | General-purpose applications, promotional items |

Ready to source the perfect neoprene sponge for your product line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and industrial materials for distributors, brand owners, and bulk clients. Our expertise in materials like CR, SCR, and SBR ensures you get the right balance of performance, color options, and cost-efficiency for your specific needs.

Contact our experts today for a consultation and let us help you select and manufacture the ideal neoprene solution.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

People Also Ask

- Why are boots considered a must-have in every man's wardrobe? Unlock Style, Durability & Versatility

- What are the advantages of using recycled nylon yarn from fishing nets? High-Performance Gear Meets Sustainability

- How does cement construction differ from welted construction? Choose the Right Method for Durability & Cost

- What are the best cowboy boot shapes for wide feet? Find Your Perfect, Comfortable Fit

- Why are multiple miniature vibration motors integrated into smart footwear? Enhancing Haptic Navigation & Safety

- Why is barefoot walking used as a baseline in gait safety research? Unlocking Natural Biomechanics for Shoe Design

- What is the function of specialized plantar pressure shoes in an MTVBWS system? Unlock Real-Time Gait Analysis

- What is the primary role of professional sports footwear in the rehabilitation process of stroke patients? Key Benefits