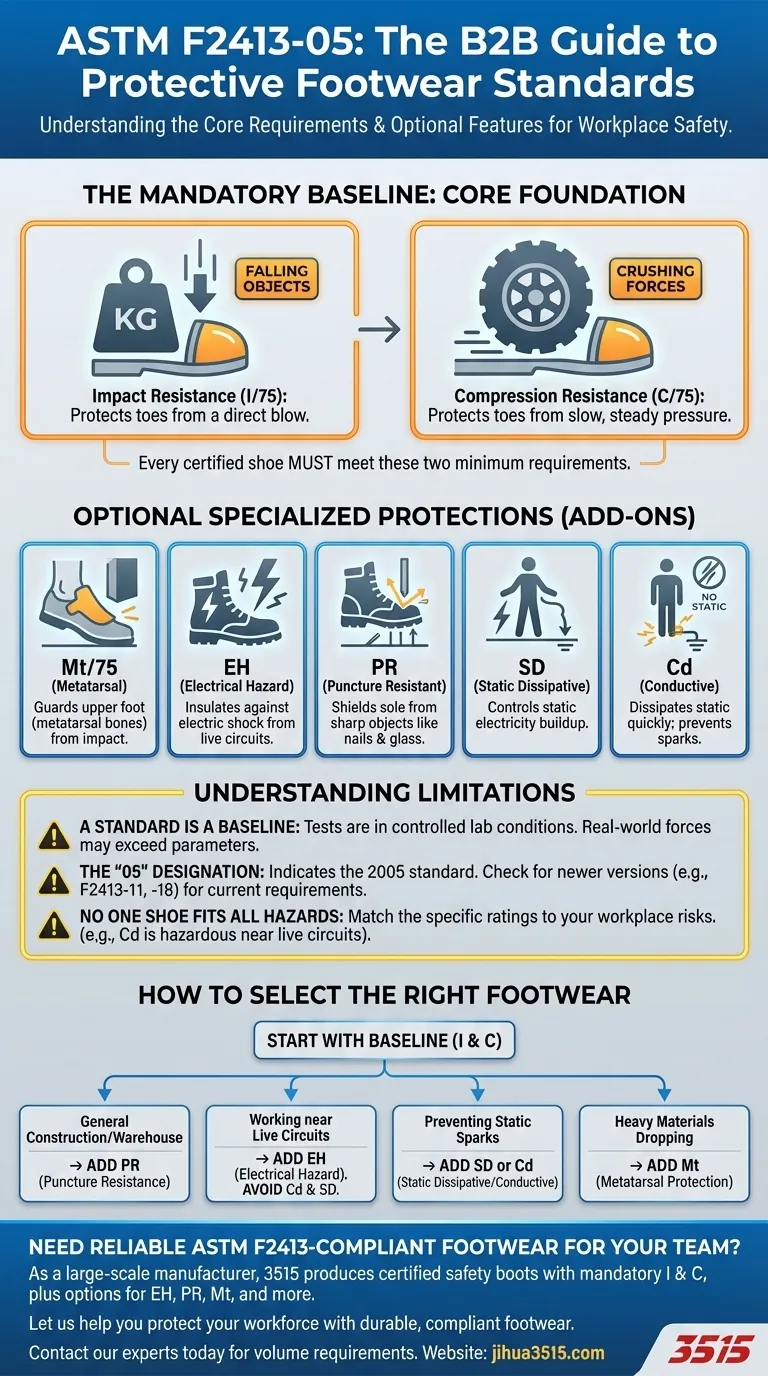

At its core, the ASTM F2413-05 standard for protective footwear mandates two fundamental safety features. Every piece of footwear certified under this standard must first meet the minimum requirements for impact resistance and compression resistance for the toe area. From this baseline, additional, more specialized protections can be added to address specific workplace hazards.

The standard establishes a non-negotiable foundation of toe protection against falling objects (impact) and crushing forces (compression). All other F2413-05 ratings for features like electrical protection or puncture resistance are optional additions built upon this core requirement.

The Foundation: Impact and Compression Resistance

To understand ASTM F2413-05, you must first understand its two mandatory components. These requirements ensure the safety cap in the footwear can protect the toes from common workplace accidents.

What is Impact Resistance?

Impact resistance measures the toe cap's ability to protect the foot from a direct blow from a falling object. During testing, a specified weight is dropped from a set height onto the toe cap.

The footwear passes if the toe cap maintains a minimum clearance inside the shoe after the impact, preventing the toes from being crushed.

What is Compression Resistance?

Compression resistance measures the toe cap's ability to withstand slow, steady pressure, such as a vehicle's wheel rolling over the foot.

The test involves applying a heavy, compressive load to the toe cap. Like the impact test, the footwear passes if the toe cap preserves a minimum interior clearance, protecting the toes from being flattened.

Beyond the Basics: Optional Protective Features

Once a shoe meets the mandatory impact and compression standards, it can be tested and certified for a range of specialized hazards. These are identified by specific codes on the shoe's label.

Metatarsal (Mt) Protection

This feature includes a guard that extends from the toe cap to protect the upper part of the foot (the metatarsal bones) from impact. It is crucial in environments where objects could fall or be dropped directly on top of the foot.

Electrical Hazard (EH) Protection

Footwear with an EH rating is designed to insulate the wearer from the ground, significantly reducing the risk of electric shock from accidental contact with live electrical circuits. The entire outsole and heel are made from a non-conductive material.

Conductive (Cd) Protection

Cd-rated footwear serves the opposite purpose of EH footwear. It is designed to dissipate static electricity from the body into the ground, preventing static sparks that could ignite flammable materials or damage sensitive electronics.

Static Dissipative (SD) Protection

SD footwear is a middle ground between EH and Cd. It reduces static buildup by conducting it to the ground, but it does so in a more controlled manner than conductive footwear, still offering a degree of resistance to electrical hazards.

Puncture Resistant (PR) Protection

This rating indicates that a puncture-resistant plate, typically made of steel or a composite material, is positioned in the sole of the footwear. This plate protects the bottom of the foot from sharp objects like nails, glass, or scrap metal.

Understanding the Limitations

While the ASTM standard provides a reliable benchmark for safety, it's critical to understand its context and what it does not cover.

A Standard is a Baseline

The F2413-05 standard specifies performance under controlled, laboratory conditions. Real-world accidents can involve forces that exceed these testing parameters. Certified footwear dramatically increases safety, but it does not provide absolute immunity from injury.

The "05" Designation is Key

The "05" in F2413-05 indicates that this standard was published in 2005. The ASTM F2413 standard is periodically reviewed and updated (e.g., F2413-11, F2413-18). While the core principles remain, newer versions may have revised test methods or requirements. Always check the specific requirements for your job site.

No One Shoe Fits All Hazards

A shoe designed for one hazard may be dangerous in another environment. For example, wearing Conductive (Cd) footwear in an area with live electrical circuits would be extremely hazardous. You must match the shoe's specific ratings to the known risks of your environment.

How to Select the Right F2413-Compliant Footwear

Choosing the correct footwear requires a clear understanding of your specific work environment and its associated hazards.

- If your primary focus is general construction or warehouse work: Start with the baseline Impact (I) and Compression (C) ratings and strongly consider adding Puncture Resistance (PR).

- If your primary focus is working near live electrical circuits: The Electrical Hazard (EH) rating is mandatory, and you must avoid any footwear marked as Cd or SD.

- If your primary focus is preventing static sparks (e.g., electronics assembly, handling flammables): You must select footwear with a Static Dissipative (SD) or Conductive (Cd) rating.

- If your primary focus is protection from heavy materials dropping or rolling: Seek out Metatarsal (Mt) protection in addition to the mandatory I and C ratings for the toe.

Understanding the components of the ASTM F2413 standard empowers you to move beyond simple compliance and make an informed choice for your personal safety.

Summary Table:

| Protection Type | Code | Key Function |

|---|---|---|

| Impact Resistance | I/75 | Mandatory. Protects toes from falling objects. |

| Compression Resistance | C/75 | Mandatory. Protects toes from crushing forces. |

| Metatarsal Protection | Mt/75 | Optional. Guards the upper foot from impact. |

| Electrical Hazard | EH | Optional. Reduces risk of electric shock. |

| Puncture Resistant | PR | Optional. Shields sole from sharp objects. |

| Static Dissipative | SD | Optional. Controls static electricity buildup. |

| Conductive | Cd | Optional. Dissipates static electricity quickly. |

Need reliable ASTM F2413-compliant safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. We ensure every pair meets the mandatory impact and compression requirements, with options for EH, PR, Mt, and other specialized protections tailored to your specific workplace hazards.

Let us help you protect your workforce with durable, compliant footwear.

Contact our experts today for a quote to discuss your volume requirements.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What resources can help in evaluating footwear? A Guide to Selecting the Right Safety Shoes

- What core protective functions do Industrial-grade Safety Shoes provide? Key Foot Protection for High-Risk Environments

- What is the purpose of the midsection with insert for ladder support in safety footwear? Enhance Stability & Safety

- What are the protective benefits of professional safety shoes for maritime deck operations? Ensure Maritime Safety

- How does puncture-resistant (PR) safety footwear work? The Ultimate Guide to Underfoot Protection

- What core safety benefits do industrial-grade safety shoes provide for mining? Protect Your Team from High-Intensity Risks

- What is the purpose of safety footwear? Protect Your Workforce from Critical Hazards

- What are the primary technical advantages of using Polyurethane (PUR) materials in safety footwear? Durability & Comfort