Ethylene-vinyl acetate (EVA) soles primarily function as a comfort-enhancing solution within safety footwear, prized for their lightweight nature and flexibility. While they offer distinct advantages in reducing fatigue, they are generally less robust than rubber or thermoplastic polyurethane (TPU) and are susceptible to faster physical wear in harsh environments.

While EVA is a valid option for oil-resistant footwear, its primary value lies in superior shock absorption and weight reduction rather than rugged durability. It is often best utilized as a cushioning midsole rather than the primary contact surface in heavy-duty industrial sites.

The Performance Profile of EVA

To understand if EVA is the right choice for your environment, you must look beyond the "oil-resistant" label and consider how the material physically behaves under stress.

Superior Shock Absorption

EVA is technically categorized as a foam-based polymer. Its cellular structure allows it to compress and rebound with every step.

This provides excellent impact resistance, significantly reducing the strain on your joints and back during long shifts on hard surfaces like concrete.

Lightweight Flexibility

One of the defining characteristics of EVA is its low density. Boots utilizing EVA soles are significantly lighter than those with solid rubber bottoms.

This material is also naturally flexible. It requires less break-in time and allows the foot to move more naturally compared to rigid alternatives.

The Role of the Midsole

Because of its cushioning properties, EVA is frequently cited as being ideal for midsoles and insoles.

In many high-quality boots, EVA is used as the layer between your foot and the ground to provide comfort, while a harder material handles the direct contact.

Understanding the Trade-offs

While EVA feels great on the foot, it has limitations regarding longevity and structural integrity that you must accept.

Rapid Wear and Abrasion

The primary disadvantage of EVA is that it is not very sturdy compared to other industrial materials.

References indicate that EVA tends to wear down faster than rubber or TPU. In a high-friction environment, the tread pattern may smooth out relatively quickly.

Reduced Traction Over Time

Because the material wears down faster, the grip capabilities of the sole can degrade sooner than you might expect.

While a fresh EVA sole may offer oil resistance, a smoothed-out sole becomes a slip hazard on slick, uneven, or oily floors.

Structural Compression

Over extended periods of heavy use, the foam structure of EVA can permanently compress.

Once the material "packs out," it loses its ability to absorb shock, leading to a sudden decrease in comfort and support.

Making the Right Choice for Your Goal

Selecting the right sole depends on whether your priority is immediate comfort or long-term ruggedness.

- If your primary focus is reducing fatigue on flat surfaces: Prioritize EVA for its lightweight, shock-absorbing properties that cushion your steps during long shifts.

- If your primary focus is maximum durability in abrasive environments: Opt for Rubber or TPU outsoles, as EVA will wear down too quickly to be cost-effective.

EVA offers a specific balance of comfort and function, best suited for professionals who need agility over armor.

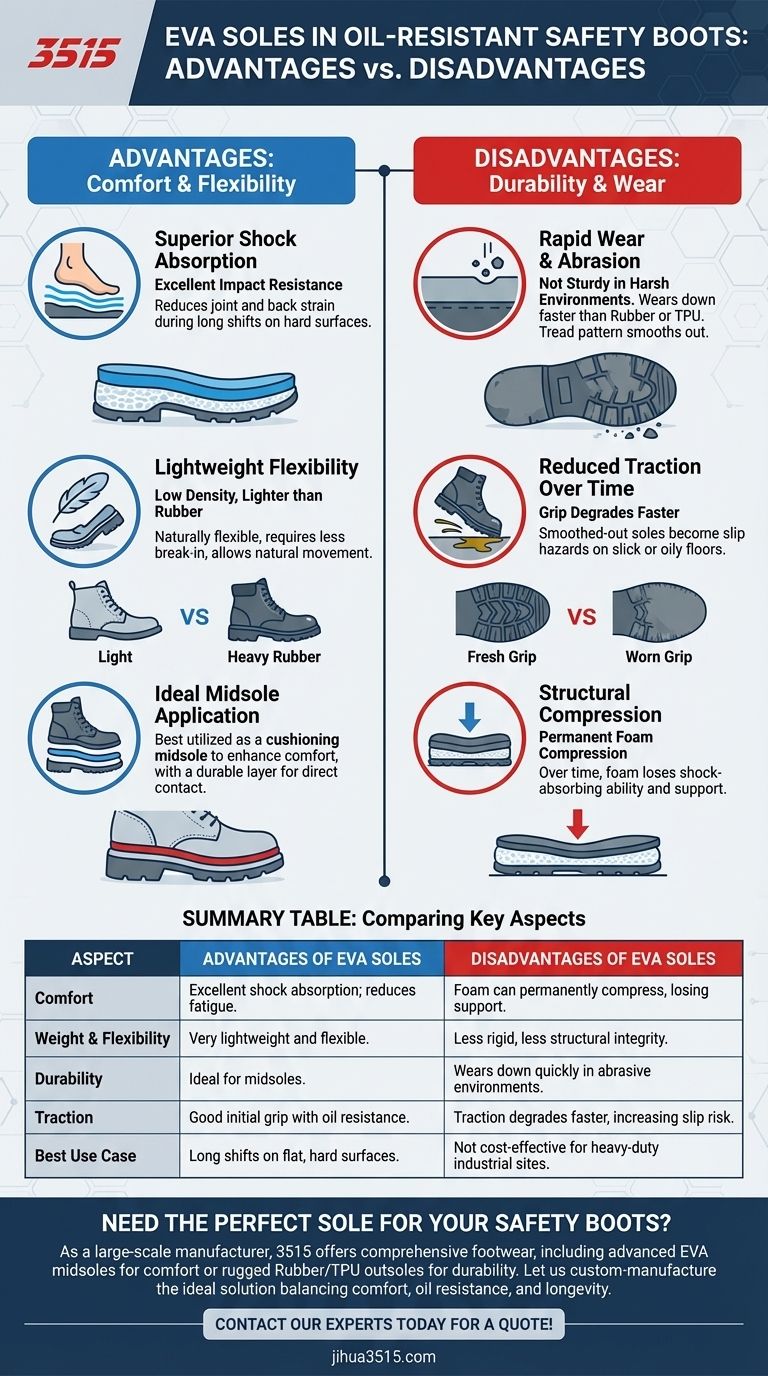

Summary Table:

| Aspect | Advantages of EVA Soles | Disadvantages of EVA Soles |

|---|---|---|

| Comfort | Excellent shock absorption; reduces joint and back fatigue. | Foam can permanently compress over time, losing support. |

| Weight & Flexibility | Very lightweight and flexible; requires less break-in time. | Less rigid, offering less structural integrity than rubber or TPU. |

| Durability | Ideal for midsoles to enhance overall boot comfort. | Wears down quickly in abrasive environments; tread can smooth out. |

| Traction | Provides good initial grip with oil resistance. | Traction degrades faster as the sole wears down, increasing slip risk. |

| Best Use Case | Long shifts on flat, hard surfaces where reducing fatigue is key. | Not cost-effective for heavy-duty, high-abrasion industrial sites. |

Need the perfect sole for your safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including models with advanced EVA midsoles for superior comfort or rugged rubber/TPU outsoles for maximum durability.

Let us help you select or custom-manufacture the ideal safety footwear that balances comfort, oil resistance, and longevity for your specific workforce and environment.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What does the infographic mentioned in the article cover? Prevent Workplace Foot Injuries with the Right Safety Footwear

- What materials are used in non-steel safety toes? A Guide to Lighter, Safer Footwear

- What is the primary purpose of industrial-grade safety shoes? Protect Workers with Superior Hazard Defense

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety

- What role does a virtual last play within a customized safety shoe production system? The Digital DNA of Footwear Design

- What types of toe protection are available in safety Wellington boots? Steel vs. Composite Toe Caps

- What is the primary function of wireless pressure-sensing insoles? Enhance Industrial Safety with Real-Time Monitoring

- How does the 10-meter walk test reflect the impact of safety shoes on operational efficiency? Maximize Worker Mobility