To get a truly accurate boot measurement, you must measure your feet at the end of the day, while wearing the exact socks you intend to use with the boots. Always measure both feet while standing under your full body weight and use the larger of the two measurements as your guide, as feet are rarely the same size.

An accurate measurement isn't just about finding a number; it's about simulating the real-world conditions your foot will experience inside the boot. The goal is to measure your foot in its most expanded state—at the end of the day, with the right socks, and under your body's full weight.

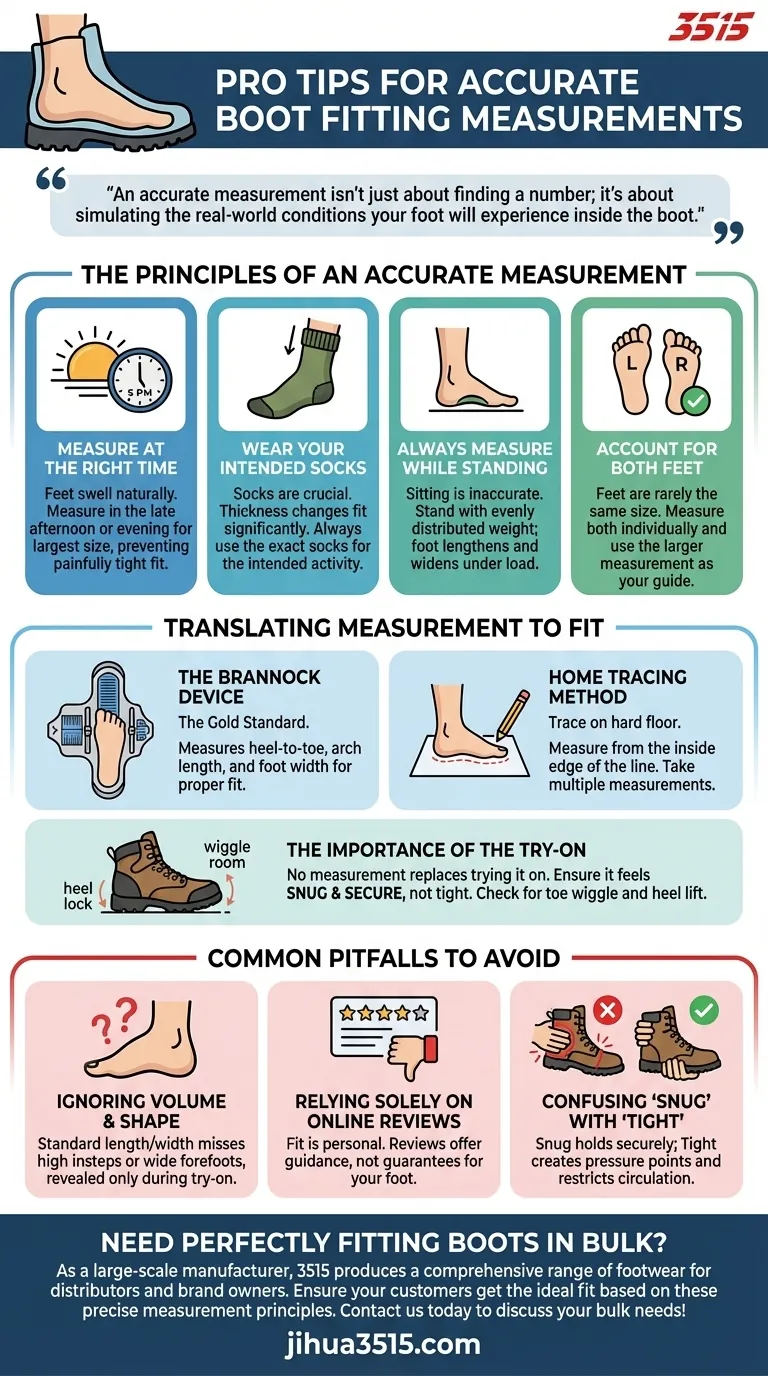

The Principles of an Accurate Measurement

Achieving a perfect fit begins long before you try on a boot. It starts with a foundational measurement process that accounts for how your feet change based on time, pressure, and accessories.

Measure at the Right Time of Day

Your feet naturally swell and expand throughout the day due to gravity and activity.

A measurement taken in the morning reflects your foot at its smallest. For performance footwear, it is critical to measure in the late afternoon or evening to capture your foot's largest size, preventing a fit that becomes painfully tight after a few hours of use.

Wear Your Intended Socks

Socks are a crucial component of your boot's fit system, not an afterthought. The thickness of a sock can easily change the fit by a half-size or more.

Always conduct your measurements and try-ons while wearing the specific socks you will use for the intended activity, whether they are thick wool hiking socks or thin daily-wear socks.

Always Measure While Standing

Your foot arch flattens and the foot itself lengthens and widens when you put weight on it.

A sitting measurement will be inaccurate. Stand with your weight evenly distributed to ensure the measurement reflects the true, load-bearing dimensions of your foot.

Account for Both Feet

Almost everyone has one foot that is slightly larger than the other. Sizing your boots to the smaller foot is a direct path to blisters and discomfort.

Always measure both feet individually and use the length and width of the larger foot as your definitive size.

Translating Measurement to Fit

A number is just a starting point. The next step is to apply that data in a real-world context, whether at home, in a store, or online.

The Brannock Device: The Gold Standard

The most reliable tool for measurement is a Brannock Device, found at most reputable shoe stores. It measures not only heel-to-toe length but also arch length and foot width, which are critical for a proper fit.

The Home Tracing Method

If you are measuring at home, place a piece of paper on a hard floor and trace the outline of your foot. To avoid errors from the width of your pencil, make sure you measure from the inside edge of the traced line.

Take multiple measurements to ensure consistency before consulting a brand's sizing chart.

The Importance of the Try-On

No measurement can replace the feel of trying on the boot. When you do, check that your foot feels snug and secure without being tight.

You should have enough room to wiggle your toes, but your heel should not lift excessively when you walk. Your foot should not slide forward and jam your toes into the front of the boot, especially on an incline.

Common Pitfalls to Avoid

Even with perfect measurements, common mistakes can undermine the entire process. Being aware of them is key to avoiding a poor purchase.

Ignoring Foot Volume and Shape

Standard length and width measurements don't account for factors like a high instep, a narrow heel, or a wide forefoot. These unique aspects of your foot shape are only revealed during an in-person try-on.

Relying Solely on Online Reviews

Reviews can offer helpful guidance, such as whether a boot model generally runs large or small. However, fit is highly personal. Never treat another person's experience as a guarantee of how a boot will fit you.

Confusing 'Snug' with 'Tight'

A proper fit should be snug, meaning your foot is securely held in place without excess movement. It should not be tight, which creates pressure points, restricts circulation, or causes pinching.

Making the Right Choice for Your Activity

Your intended use for the boot dictates which fitting principles are most critical.

- If your primary focus is hiking or strenuous work: Prioritize a late-day measurement with your thickest activity socks to accommodate foot swelling and prevent blisters on the trail or job site.

- If your primary focus is casual or daily wear: A late afternoon measurement is still best, but you have slightly more tolerance than you would with technical footwear.

- If you are buying online without trying on: Measure meticulously, compare your results to the brand's specific sizing chart, and consider ordering two sizes to return the one that doesn't fit.

Ultimately, a precise measurement is the critical first step toward ensuring your boots support your goals, rather than hinder them.

Summary Table:

| Key Measurement Principle | Why It Matters |

|---|---|

| Measure in the Late Afternoon | Feet swell during the day; ensures boots fit when feet are largest. |

| Wear Your Intended Socks | Sock thickness changes fit by up to half a size; prevents incorrect sizing. |

| Stand Under Full Body Weight | Foot lengthens and widens when standing; provides true load-bearing dimensions. |

| Measure Both Feet & Use Larger Size | Most people have one foot larger; prevents blisters and discomfort. |

Need perfectly fitting boots in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring your customers get the ideal fit based on these precise measurement principles. Let us help you deliver superior comfort and performance. Contact our team today to discuss your bulk footwear needs!

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How do dress boots differ from field boots? A Guide to Choosing the Right Equestrian Boot

- How do e-commerce platforms facilitate transaction conversion? Modernize Your Global Footwear Supply Chain Today

- What role do 3-axis MEMS accelerometers play in the detection of gait abnormalities? Insights for Smart Footwear.

- What is the function of Visual Analog Scale (VAS) questionnaires? Quantify Footwear Comfort & Perceived Value

- What is the function of 3D modeling software like SolidWorks in shoe sole slip resistance? Optimize Grip & Performance

- What role do high-precision wearable motion sensors play in assessing footwear impact? Achieve Scientific Precision

- Why is the control of stance time a critical indicator in footwear R&D? Engineering Speed Through Movement Efficiency

- What is the function of the standardized Nordic Musculoskeletal Questionnaire (NMQ)? Key Insights for Occupational Health