Achieving the correct fit for safety footwear requires balancing anatomical alignment with functional protection. You must prioritize a secure heel lock, approximately 12.5mm of toe clearance, and sufficient internal volume to accommodate the natural foot swelling that occurs during a work shift.

True workplace safety is a function of fit. A boot that meets technical standards but fits poorly will compromise your stability, increase fatigue, and ultimately reduce the effectiveness of its protective features.

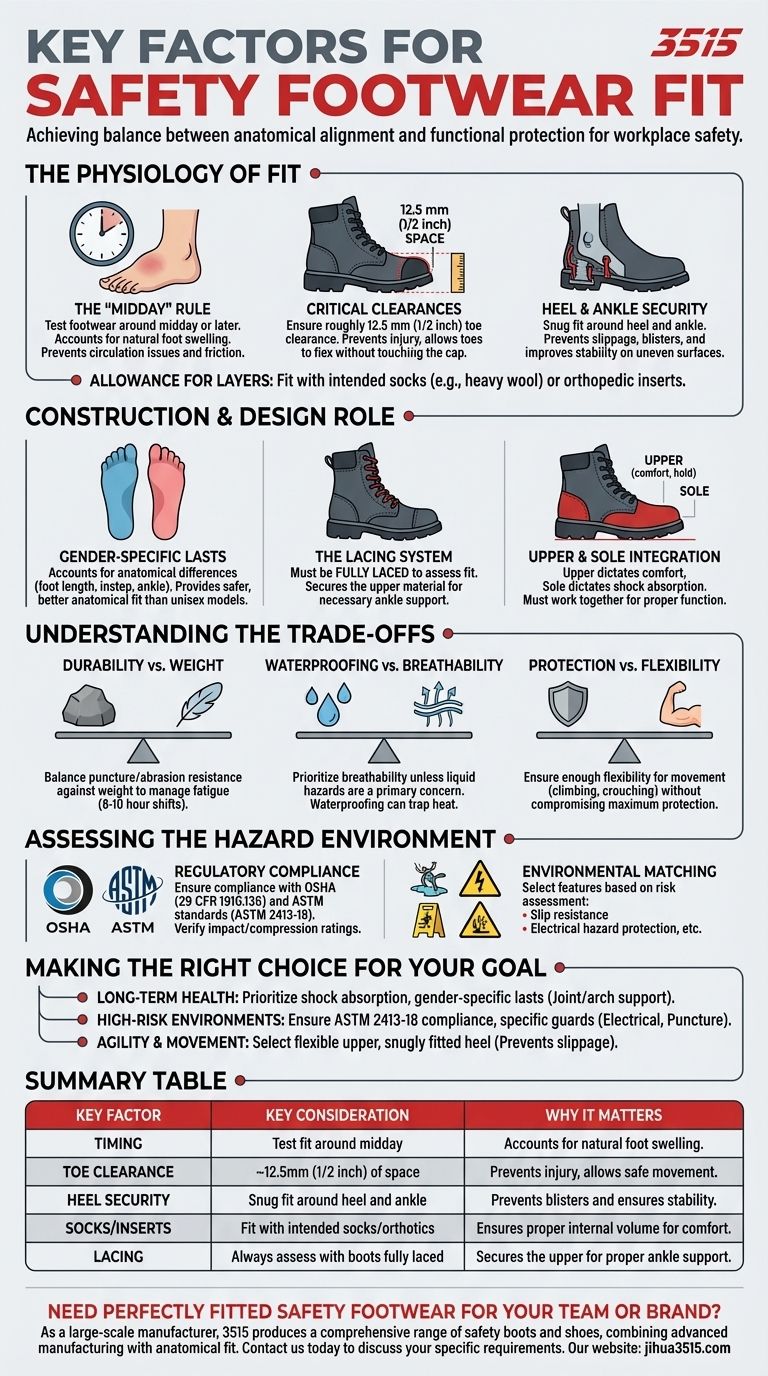

The Physiology of Fit

The "Midday" Rule

Never test footwear at the start of the day. Your feet naturally swell and expand as you stand and work.

Test new boots around midday or later. This ensures the fit accommodates your foot at its largest volume, preventing circulation issues or friction points later in the shift.

Critical Clearances

To prevent injury to the toes—especially when steel or composite caps are involved—you need adequate space.

Ensure there is roughly 12.5 mm (1/2 inch) of space between your longest toe and the front of the boot. The toes should not touch the protective cap when you walk or flex.

Heel and Ankle Security

While the toes need room, the rear of the foot must be locked in place.

The boot should fit snugly around the heel and ankle. Slippage here leads to blisters and reduces the stability required for uneven surfaces.

Allowance for Support Layers

Do not fit the boot wearing thin dress socks if you plan to wear heavy wool socks or use orthopedic inserts.

You must make allowances for extra socks or arch supports during the fitting process to ensure the internal volume remains sufficient.

The Role of Construction and Design

Gender-Specific Lasts

A "last" is the mold used to shape the boot. Universal sizing often fails because it ignores anatomical differences.

Look for manufacturers using gender-specific lasts. These account for differences in foot length, instep height, and ankle height, providing a safer anatomical fit than "unisex" models.

The Lacing System

The lacing system is part of the boot's safety architecture, not just a closure method.

Boots must be fully laced to assess fit accurately. A proper lacing system secures the upper material (padding and lining) against the foot, providing necessary ankle support.

Upper and Sole Integration

Understand that the fit is influenced by how the upper interacts with the sole.

The upper (lining, padding, and heel cap) dictates comfort and hold, while the sole (outsole and midsection) dictates shock absorption. If the sole is too rigid for your stride, the upper will chafe regardless of the size.

Understanding the Trade-offs

Durability vs. Weight

Higher durability often requires heavier materials and thicker soles.

While this increases longevity, it can increase fatigue. You must balance the need for puncture and abrasion resistance against the weight you can comfortably move in for 8-10 hours.

Waterproofing vs. Breathability

Waterproofing protects against environmental moisture and corrosive substances, but it often traps heat.

If you work in hot, dry environments, a waterproof membrane may cause excessive sweating, leading to blisters. Prioritize breathability unless liquid hazards are a primary concern.

Protection vs. Flexibility

Heavy-duty metatarsal guards and tall shafts offer maximum protection but limit range of motion.

Ensure the boot allows enough flexibility for you to perform tasks like climbing ladders or crouching without cutting off circulation.

Assessing the Hazard Environment

Regulatory Compliance

Fit extends beyond the foot; the boot must "fit" the regulatory requirements of your job site.

You must ensure compliance with OSHA regulations (29 CFR 1910.136) and ASTM standards (ASTM 2413-18). This includes verifying impact resistance and compression ratings.

Environmental Matching

Identify the specific risks: falling objects, electrical hazards, or wet surfaces.

Select features like slip resistance or electrical hazard protection based on a specific risk assessment. A boot that fits your foot perfectly is the wrong choice if it lacks the specific shielding your environment demands.

Making the Right Choice for Your Goal

Always contextualize the fit within your specific work environment.

- If your primary focus is Long-Term Health: Prioritize shock absorption and gender-specific lasts to minimize strain on your joints and arches.

- If your primary focus is High-Risk Environments: Ensure the boot meets ASTM 2413-18 standards and includes specific guards for electrical or puncture hazards.

- If your primary focus is Agility and Movement: Select a boot with a flexible upper and a snugly fitted heel to prevent slippage on uneven terrain.

The best safety footwear disappears while you work, providing protection without demanding your attention.

Summary Table:

| Key Factor | Key Consideration | Why It Matters |

|---|---|---|

| Timing | Test fit around midday | Accounts for natural foot swelling during the workday. |

| Toe Clearance | ~12.5mm (1/2 inch) of space | Prevents injury and allows for safe movement. |

| Heel Security | Snug fit around heel and ankle | Prevents blisters and ensures stability. |

| Socks/Inserts | Fit with intended socks/orthotics | Ensures proper internal volume for all-day comfort. |

| Lacing | Always assess with boots fully laced | Secures the upper material for proper ankle support. |

Need perfectly fitted safety footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. We combine advanced manufacturing with an understanding of anatomical fit to deliver footwear that meets the highest safety standards without compromising on comfort.

Our production capabilities encompass all types of safety shoes and boots, designed to protect your workforce effectively.

Contact us today to discuss your specific requirements and discover how we can support your safety goals.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How has safety footwear evolved over time? From Wooden Sabots to Smart Boots

- Why is choosing the right safety toe boot important? Protect Your Feet and Prevent Injury

- What role do industrial safety shoes play in improving the labor environment? Boost Safety and Reduce Worker Stress

- What factors should be considered for comfort in safety-toe boots? Ensure All-Day Comfort and Performance

- How do professional-grade safety shoes provide comprehensive protection for welders? Master Industrial Safety Standards

- What core features are required in high-performance safety shoes? Gear for Extreme Heat & Complex Environments

- How does the implementation of a safety stock warning system ensure the continuous supply of specialty protective shoes?

- How is the Functional Reach Test utilized to measure the stability limits of safety shoes? Enhancing Industrial Safety