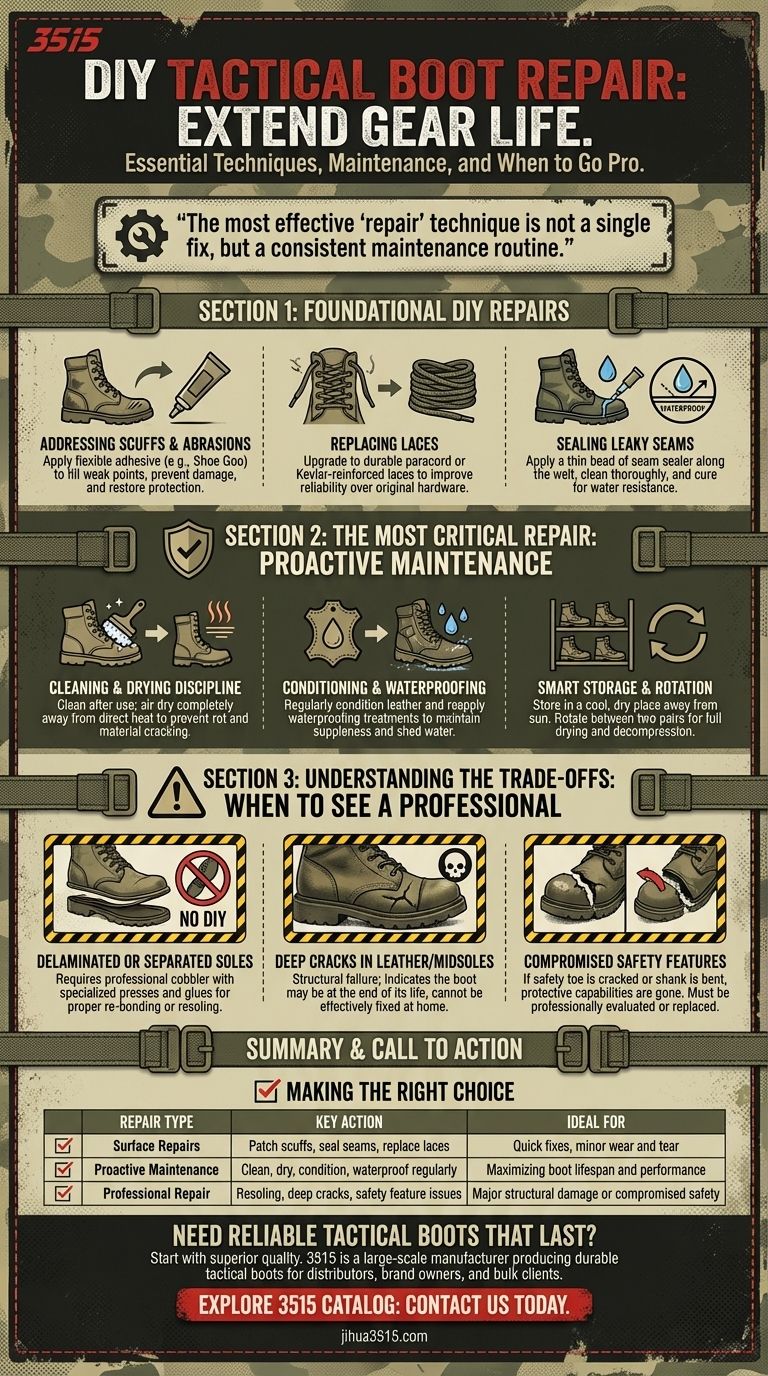

For tactical boots, the most common DIY repairs involve addressing surface-level wear and tear. You can easily patch scuffs, seal minor leaks in seams with specialized adhesives, and replace worn-out laces or damaged eyelets to significantly extend the functional life of your footwear.

The most effective "repair" technique is not a single fix, but a consistent maintenance routine. Proactive care prevents the material degradation that leads to most common boot failures.

Foundational Repairs You Can Perform

Simple repairs can keep your boots in service longer, addressing the most common points of failure that don't compromise the boot's core structure.

Addressing Scuffs and Abrasions

Scuffs on leather or synthetic materials are more than cosmetic; they are weak points. Applying a flexible adhesive like Shoe Goo or a dedicated leather repair compound can fill these areas, preventing further damage and restoring a layer of protection.

Replacing Laces

Worn or frayed laces are a primary failure point. This is the simplest repair, and upgrading to durable paracord or Kevlar-reinforced laces can improve reliability over the original hardware.

Sealing Leaky Seams

If you notice moisture seeping in around the welt (where the upper meets the sole), a thin bead of seam sealer can often solve the problem. Clean the area thoroughly, apply the sealer, and allow it to cure completely to restore water resistance.

The Most Critical Repair: Proactive Maintenance

While direct repairs fix existing problems, a disciplined maintenance schedule prevents them from ever happening. This is the true key to gear longevity.

The Cleaning and Drying Discipline

Dirt and mud hold moisture against boot materials, accelerating rot and decay. Clean your boots regularly after use and, critically, allow them to air dry completely away from direct heat sources like fires or vents, which can crack leather and weaken adhesives.

Conditioning and Waterproofing

Leather boots require conditioning to keep the material supple and prevent cracking. For all tactical boots, periodically reapplying a waterproofing treatment maintains their ability to shed water and protect the underlying materials.

Smart Storage and Rotation

Storing boots in a cool, dry place away from direct sunlight prevents UV damage and material breakdown. If possible, rotating between two pairs allows each pair to fully dry and decompress, drastically extending the life of both.

Understanding the Trade-offs: When to See a Professional

DIY repairs have their limits. Attempting to fix major structural issues can cause irreparable damage or compromise your safety.

Delaminated or Separated Soles

If the main outsole is peeling away from the boot, a simple adhesive will not hold under field conditions. A professional cobbler has the specialized presses and glues required to properly re-bond or completely resole the boot.

Deep Cracks in Leather or Midsoles

Surface-level cracks can be sealed, but deep fissures in the boot's upper or cushioning midsole indicate a structural failure. These cannot be effectively repaired at home and signal that the boot may be at the end of its life.

Compromised Safety Features

If a composite safety toe is cracked or a puncture-resistant shank is bent, the boot's protective capabilities are gone. These boots must be professionally evaluated or, more often, replaced.

Making the Right Choice for Your Goal

Your immediate need dictates the correct course of action.

- If your primary focus is a quick field fix: Carry a small roll of Gorilla Tape or a spare set of laces for immediate, temporary repairs.

- If your primary focus is maximizing boot lifespan: Adopt a strict cleaning, drying, and conditioning routine as your default procedure after every use.

- If your primary focus is restoring lost performance: Focus on specific tasks like applying seam sealer to fix a leak or using a repair compound on worn areas.

Ultimately, treating your boots as a critical system that requires regular maintenance is the best strategy for ensuring they perform when you need them most.

Summary Table:

| Repair/Maintenance Type | Key Action | Ideal For |

|---|---|---|

| Surface Repairs | Patch scuffs, seal seams, replace laces | Quick fixes, minor wear and tear |

| Proactive Maintenance | Clean, dry, condition, waterproof regularly | Maximizing boot lifespan and performance |

| Professional Repair | Resoling, fixing deep cracks, safety feature issues | Major structural damage or compromised safety |

Need Reliable Tactical Boots That Last?

While DIY repairs can extend the life of your gear, starting with superior-quality footwear is the best strategy. As a large-scale manufacturer, 3515 produces a comprehensive range of durable tactical boots for distributors, brand owners, and bulk clients. Our production capabilities ensure every pair is built to withstand demanding conditions from the start.

Let's discuss your needs: Contact our team today to explore our catalog and find the perfect tactical footwear solution for your market.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- What are the footwear requirements for special operations? Mission-Specific Boots for Peak Performance

- What is the necessity of structural flexibility and high-response soles? Maximize Tactical Agility and Speed

- How are environmental condition sensors utilized in the design of outdoor tactical training footwear and equipment? Boost Performance & Safety

- What technical features allow tactical boots and outdoor shoes to enhance safety? Engineering for Complex Terrain

- What function do embedded electromagnetic sensor coils perform in the landmine warning process? Boost Soldier Safety

- What are the technical advantages of using tactical boots with high thermal resistance? Master Winter Heat Retention

- Are combat boots suitable for civilian use? A Guide to Durability, Style, and Practicality

- How do tactical boots provide reinforcement and protection? A Guide to Their Defensive Engineering