At their core, oilfield boots are a critical piece of personal protective equipment specifically engineered to protect workers from the unique and severe hazards of the oil and gas industry. Unlike standard work boots, they are designed as a complete safety system, focusing on extreme durability, specialized traction, and resistance to the specific dangers found on a rig or well site.

The defining purpose of an oilfield boot isn't just to be tough; it's to provide a multi-layered defense system against the predictable and unpredictable dangers of the job. Choosing the right boot means understanding the specific hazards you will face each day.

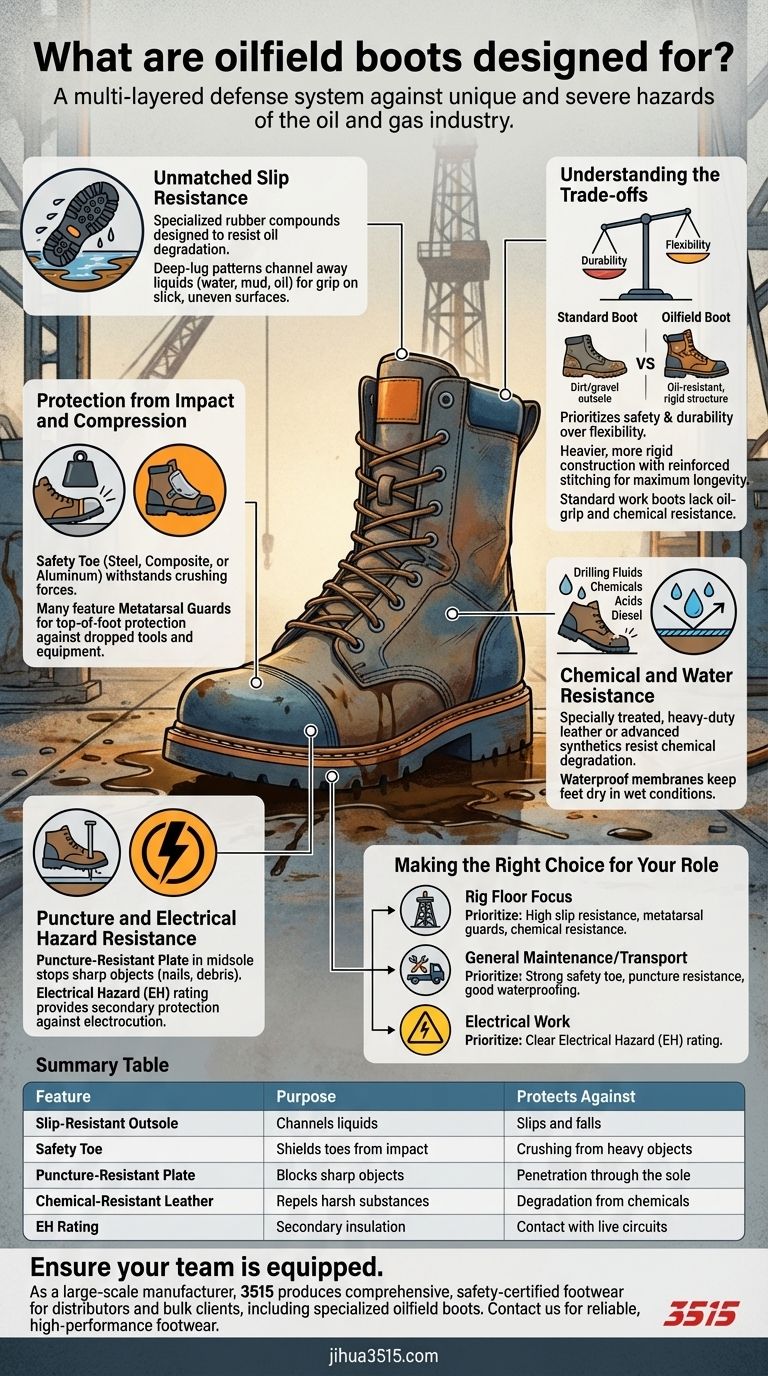

The Anatomy of an Oilfield Boot: Engineered for Hazards

To understand what oilfield boots are designed for, you must look at how their individual components directly counter the risks of the environment. Each feature is a solution to a specific problem.

Unmatched Slip Resistance

The floor of a drilling rig is a constantly changing surface, often covered in water, drilling mud, oil, and other slick fluids. This makes slips and falls a primary cause of injury.

Oilfield boots feature outsoles made from specialized rubber compounds designed to resist degradation from oil. They have aggressive, deep-lug patterns that are purpose-built to channel liquids away and maintain grip on slick, uneven metal or composite decking.

Protection from Impact and Compression

The risk of heavy objects falling or rolling onto feet is constant in the oil and gas industry. This includes everything from dropped tools to shifting pipes and equipment.

Virtually all oilfield boots include a safety toe, which can be made of steel, a composite material, or an aluminum alloy. These are rated to withstand significant impact and compression forces, protecting the toes from being crushed. Many also feature metatarsal guards that extend protection to the top of the foot.

Puncture and Electrical Hazard Resistance

The ground on an oilfield site can be littered with sharp objects like metal shavings, nails, and other debris. Furthermore, the presence of heavy machinery creates a risk of contact with live electrical circuits.

Many boots incorporate a puncture-resistant plate in the midsole to prevent sharp objects from penetrating the bottom of the foot. An Electrical Hazard (EH) rating signifies that the boot's construction provides a secondary source of protection against electrocution.

Chemical and Water Resistance

Workers are frequently exposed to a variety of harsh substances, including drilling fluids, chemicals, acids, and diesel. These materials can quickly degrade standard leather or synthetic footwear.

Oilfield boots use specially treated, heavy-duty leather or advanced synthetic materials designed to withstand chemical exposure. They also frequently feature waterproof membranes to keep feet dry during long shifts in wet conditions.

Understanding the Trade-offs

Choosing a boot designed for the oilfield means accepting certain trade-offs. These boots prioritize safety and durability above all else, which influences their design and feel.

The Problem with Standard Work Boots

A standard construction boot, while protective, is not built for the unique combination of hazards on a rig. Its outsole is typically designed for dirt and gravel, not for gripping surfaces coated in oil and drilling mud. It may also lack the necessary chemical resistance.

Durability Often Means More Rigidity

To withstand the extreme wear and tear, oilfield boots are built with reinforced stitching, thicker materials, and a more rigid structure. This can make them heavier and less flexible than other footwear, a necessary compromise for maximum protection and longevity.

The Myth of the "Rigger Boot"

While the term "rigger boot" is often used, traditional pull-on styles have fallen out of favor on many sites. Lace-up boots provide superior ankle support and are far less likely to be pulled off if a worker's foot becomes trapped, a critical safety consideration.

Making the Right Choice for Your Role

Your specific job on the site dictates which features are most critical. Analyze your daily tasks to determine your primary risks.

- If your primary focus is working on the rig floor: Prioritize boots with the highest slip-resistance rating, integrated metatarsal guards, and excellent chemical resistance.

- If your primary focus is general site maintenance or transport: A boot with a strong safety toe, puncture resistance, and good waterproofing will likely serve your needs.

- If your primary focus involves electrical work: Ensure your boots carry a clear and current Electrical Hazard (EH) rating.

Ultimately, an oilfield boot is not an expense but an essential and non-negotiable investment in your personal safety.

Summary Table:

| Feature | Purpose | Protects Against |

|---|---|---|

| Slip-Resistant Outsole | Channels oil, mud, and water | Slips and falls on slick surfaces |

| Safety Toe (Steel/Composite) | Shields toes from impact | Crushing from heavy objects |

| Puncture-Resistant Plate | Blocks sharp objects | Penetration through the sole |

| Chemical-Resistant Leather | Repels harsh substances | Degradation from oils, acids, and chemicals |

| Electrical Hazard (EH) Rating | Provides secondary insulation | Contact with live circuits |

Ensure your team is equipped with the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized work boots, including oilfield boots designed to meet the highest safety standards. Contact us today to discuss your specific needs and get a quote for reliable, high-performance footwear.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why is a proper fit important for work-safe boots? The Foundation of Safety, Comfort & Performance

- What are three key reasons to wear insulated work boots in winter? Essential Protection for Cold Work

- What features should agricultural workers look for in work boots? A Guide to Safety and Durability

- What additional safety features are available in some rubber and PVC work boots? Enhance Workplace Safety with Advanced Protection

- What problems can occur with frozen boots in winter cycling? Avoid Painful Blisters and Cold Feet

- What additional features do wildland boots have? Unmatched Protection for Extreme Conditions

- How should work boots fit properly? A Guide to All-Day Comfort and Safety

- What does metatarsal protection in ASTM standards involve? Essential Guide to Instep Safety