At their core, combat boot laces are made from high-performance synthetic materials engineered for extreme durability and environmental resistance. The most common materials are nylon, polyester, and paracord, each chosen specifically to withstand the harsh conditions of military and tactical use.

The material used for a combat boot's laces is not a stylistic choice; it is a critical component of a larger system, selected for unwavering strength, resistance to the elements, and in some cases, life-saving utility.

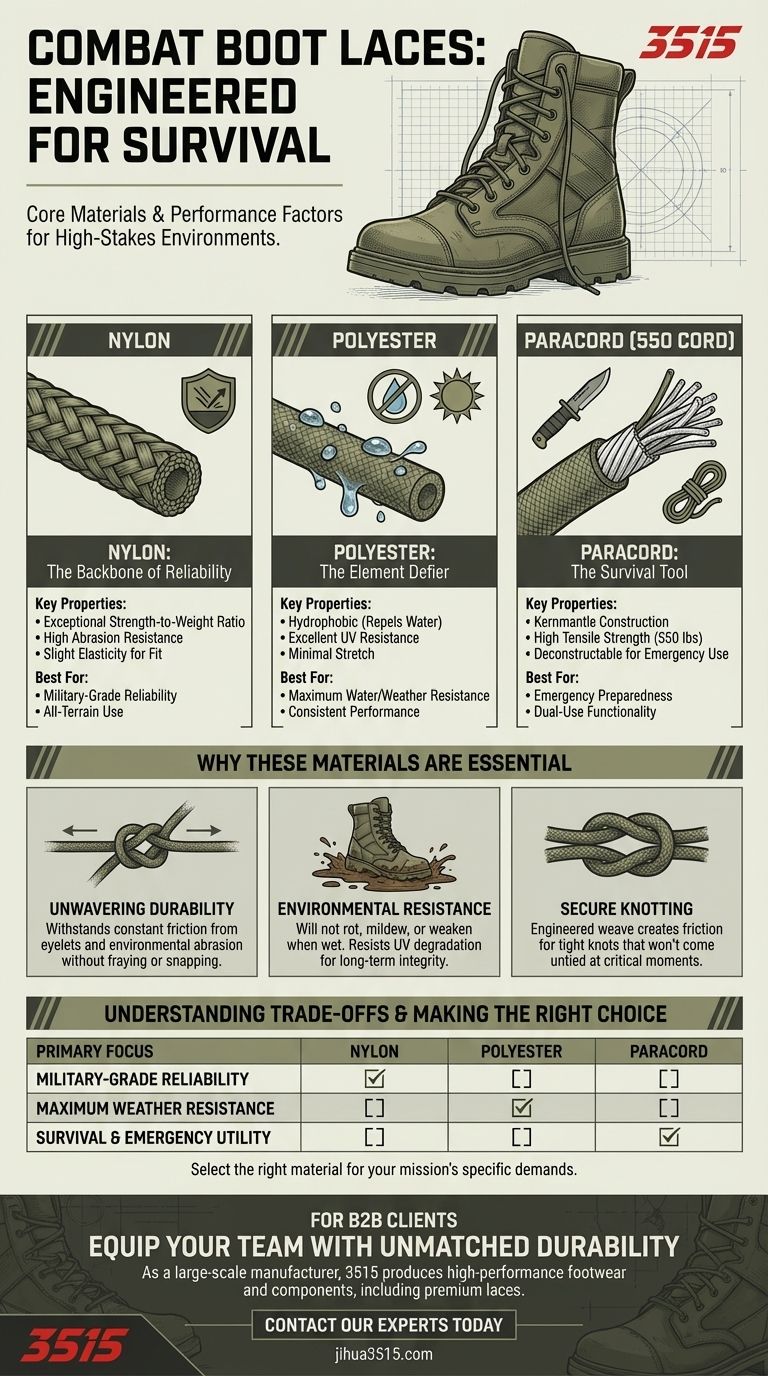

The Core Materials of Combat Laces

The demands placed on combat boots require laces made from materials that will not fail. Natural fibers like cotton are completely unsuitable as they absorb water, rot, and snap easily under strain.

Nylon

Nylon is prized for its exceptional strength-to-weight ratio and abrasion resistance. It has a slight elasticity, which can help maintain a snug fit as you move, but it is engineered to prevent excessive stretching.

Polyester

Polyester is another common choice, known for being hydrophobic, meaning it naturally repels water. This prevents the laces from becoming waterlogged, heavy, or frozen. It also offers excellent resistance to UV degradation.

Paracord (550 Cord)

Paracord is a specialized type of nylon rope with a unique kernmantle construction (a core of smaller strands protected by a woven outer sheath). It is not just a lace but a survival tool, valued for its high tensile strength and the ability to be deconstructed for emergency use.

Why These Materials Are Essential

The selection of these synthetic fibers is a direct response to the operational environment. The goal is to create a lace that is essentially "fire and forget"—it works without fail so the user can focus on their mission.

Unwavering Durability

Combat boot laces are constantly subjected to friction from metal eyelets and abrasion from rocks, dirt, and debris. Nylon and polyester are chosen for their ability to withstand this constant wear without fraying or snapping.

Resistance to Environmental Factors

In the field, boots are exposed to water, mud, and extreme temperatures. These synthetic materials will not rot, grow mildew, or weaken when wet, ensuring reliability across all conditions.

Secure Knotting

The weave and texture of these laces are designed to create friction, which helps hold a tight knot securely. A boot that comes untied at a critical moment is a significant liability, and these materials are engineered to prevent that.

Understanding the Trade-offs

While all are excellent choices, there are minor differences to consider based on the specific application.

Nylon vs. Polyester

Nylon offers slightly better abrasion resistance and a minor degree of stretch for comfort. Polyester, on the other hand, has virtually no stretch and superior water resistance, ensuring the laces never get heavy or sag.

The Paracord Compromise

While its utility is unmatched, paracord is often thicker than standard-issue laces. This can make it difficult to thread through smaller eyelets and may require more effort to tie a knot that stays completely secure due to its rounder shape.

The Importance of Weave

Beyond the raw material, the construction of the weave (e.g., braided, flat) significantly impacts knot retention and durability. A tight, high-quality braid will always outperform a loosely woven alternative, regardless of the material.

Making the Right Choice for Your Goal

Selecting the correct lace material depends entirely on your primary intended use.

- If your primary focus is military-grade reliability: Choose a dedicated, high-quality braided nylon or polyester lace designed specifically for boots.

- If your primary focus is survival and emergency preparedness: Choose 550 paracord for its unparalleled dual-use functionality.

- If your primary focus is maximum water and weather resistance: Choose a polyester lace for its hydrophobic properties.

Ultimately, equipping your boots with the right laces is a simple but critical step in ensuring your gear will perform when it matters most.

Summary Table:

| Material | Key Properties | Best For |

|---|---|---|

| Nylon | Exceptional strength, abrasion resistance, slight elasticity | Military-grade reliability, all-terrain use |

| Polyester | Hydrophobic (repels water), UV resistant, minimal stretch | Maximum water/weather resistance, consistent performance |

| Paracord | Kernmantle construction, high tensile strength, survival utility | Emergency preparedness, dual-use functionality |

Equip Your Team with Unmatched Durability

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical and military boots, ensuring every component—down to the laces—meets the highest standards of strength and reliability.

Ready to source combat boots built to last? Contact our experts today to discuss your specific needs and discover how we can deliver superior quality at scale.

Visual Guide

Related Products

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the advantages and disadvantages of combat boots? A Guide to Durability vs. Comfort

- What makes Altberg jungle boots superior? Unpacking the Design, Performance, and Trade-offs

- What are the defining features of Combat Boots? Unmatched Durability & Protection for Demanding Environments

- What are the key features of insulated boots designed for cold weather? A Guide to Warmth, Dryness & Safety

- What are some casual outfit pairings for desert boots? Master Versatile Style for Any Occasion

- What are the main differences between combat boots and jump boots? A Guide to Purpose-Built Footwear

- What makes military boots durable? The Key Materials and Construction for Long-Lasting Footwear

- What changes were made to jungle boots in the 1980s? A Tale of Innovation and Compromise