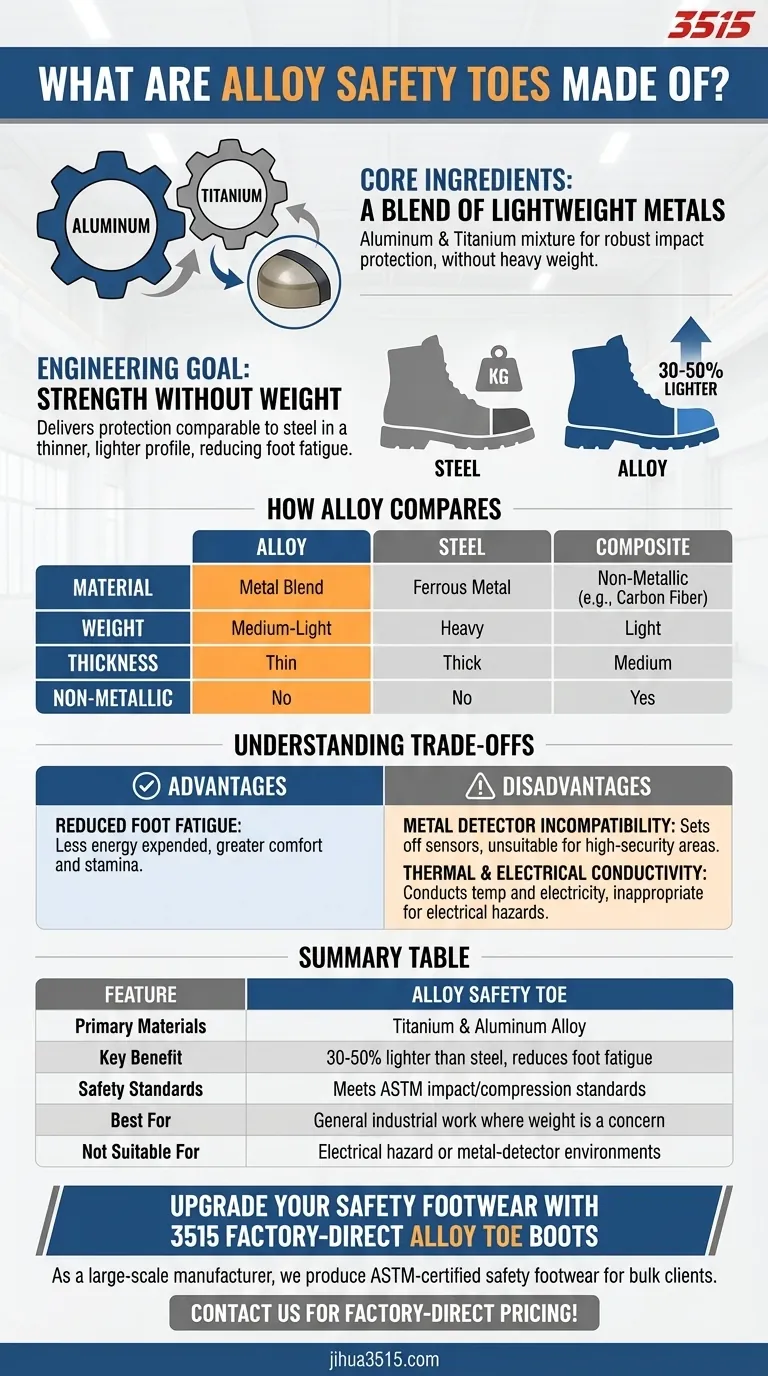

In short, an alloy safety toe is made from a mixture of lightweight but strong metals. This blend most often includes aluminum and titanium, engineered to provide robust impact protection without the heavy weight characteristic of traditional steel toes.

The central purpose of an alloy safety toe is to deliver protection comparable to steel in a significantly lighter and thinner profile. This makes it a modern alternative focused on reducing foot fatigue, though it retains the metallic properties that make it unsuitable for certain specialized work environments.

Deconstructing the "Alloy" in Alloy Toes

To understand the value of an alloy safety toe, you must first understand its composition and the engineering goal behind it. It is not a single material but a carefully selected blend.

The Core Ingredients

The term "alloy" simply means a material made by combining two or more metals. In the context of safety footwear, this almost always involves strong, low-density metals.

The most common components are titanium and aluminum. These materials are chosen for their exceptional strength-to-weight ratio, which allows for a protective cap that is both durable and easy to wear for long periods.

The Engineering Goal: Strength Without Weight

The primary objective is to reduce the weight on your feet. A traditional steel toe cap adds significant heft to a boot, which can lead to fatigue over a long workday.

By using lighter metals, manufacturers can create a safety toe that is 30-50% lighter than steel while still meeting the same stringent ASTM safety standards for impact and compression resistance.

How Alloy Compares to Other Safety Toes

Alloy toes exist in a middle ground between traditional steel and modern non-metallic options. Understanding the key differences is crucial for making an informed choice.

Alloy vs. Steel

The main advantage of alloy over steel is reduced weight and bulk. Because alloy metals are stronger for their weight, the protective cap can be made thinner. This often translates to a more spacious, comfortable toe box in the boot.

Alloy vs. Composite

This is the most critical distinction. While alloy toes are metal, composite toes are non-metallic. Composite safety toes are made from materials like carbon fiber, hard plastic, fiberglass, or Kevlar.

This non-metallic construction makes composite toes the go-to option for electricians or workers who must pass through metal detectors frequently.

Understanding the Trade-offs of Alloy Toes

No single safety toe material is perfect for every job. The benefits of alloy's lightweight design come with specific limitations tied to its metallic nature.

The Advantage: Reduced Foot Fatigue

The primary reason to choose an alloy toe is comfort. Less weight on your feet means less energy expended with every step, which can make a significant difference in comfort and stamina by the end of a long shift.

The Disadvantage: Metal Detector Incompatibility

Like steel, an alloy safety toe will set off metal detectors. This makes them unsuitable for workers in high-security environments, such as airports, nuclear facilities, or certain government buildings, who would be forced to remove their footwear repeatedly.

The Disadvantage: Thermal and Electrical Conductivity

Being a metal, alloy conducts temperature. In extremely cold or hot environments, the toe cap can become uncomfortable. More importantly, it also conducts electricity, making alloy-toed boots entirely inappropriate for electricians or others who face electrical hazards.

Making the Right Choice for Your Work Environment

Selecting the correct safety toe comes down to balancing the demands of your job against the properties of the material.

- If your primary focus is comfort and mobility: Alloy toes are an excellent choice, providing robust protection with significantly less weight than steel.

- If you work in a metal-free or electrical-hazard environment: Composite toes are the only appropriate option, as they provide the necessary protection without conductivity.

- If you need a proven, traditional safety standard: Steel remains a viable option, but alloy offers the same certified protection in a more modern, comfortable package.

Ultimately, choosing the right material is about matching the tool to the task for optimal safety and comfort.

Summary Table:

| Feature | Alloy Safety Toe |

|---|---|

| Primary Materials | Titanium & Aluminum Alloy |

| Key Benefit | 30-50% lighter than steel, reduces foot fatigue |

| Safety Standards | Meets ASTM impact/compression standards |

| Best For | General industrial work where weight is a concern |

| Not Suitable For | Electrical hazard or metal-detector environments |

Upgrade Your Safety Footwear with 3515 Factory-Direct Alloy Toe Boots

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Our alloy safety toes offer the perfect balance of lightweight comfort and uncompromised protection, ideal for reducing worker fatigue and improving productivity.

Our production capabilities encompass all types of safety shoes and boots. Let us help you equip your workforce with high-quality, comfortable safety footwear.

Contact us today for factory-direct pricing and custom solutions!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why use breathable, protective safety shoes for high-heat labor? Protect Physical Health and Renal Function

- What technical characteristics should protective footwear possess to reduce onychomycosis risk? Top Selection Tips

- What are the critical features to consider when selecting work shoes? A Guide to Safety, Comfort & Durability

- Why are insulated protective shoes necessary? Essential Protection Against High-Voltage and Electrical Leakage Risks

- How do lace-up boots perform in terms of safety? Maximize Ankle Support and Mitigate Risks

- What is the technical value of increasing Toe Spring height in diabetic footwear lasts? Enhance Protection & Mobility

- What role do integrated force plates play in the performance testing of safety footwear? Biomechanical Analysis Experts

- What are some misconceptions about the weight differences between safety toe materials? The Truth About Heavy Boots