Beyond basic flame resistance, footwear certified under NFPA 1971 for structural and proximity firefighting must pass a demanding suite of tests. These standards ensure comprehensive protection against the diverse hazards encountered in a structure fire, covering physical impacts, liquid and pathogen penetration, electrical shock, and extreme thermal exposure from both direct contact and radiant heat.

NFPA 1971 footwear standards create a complete protective system for the specific, multi-hazard environment of a structure fire. The requirements go far beyond simple heat resistance to address the chemical, biological, electrical, and physical threats that are fundamentally different from those faced in other firefighting disciplines.

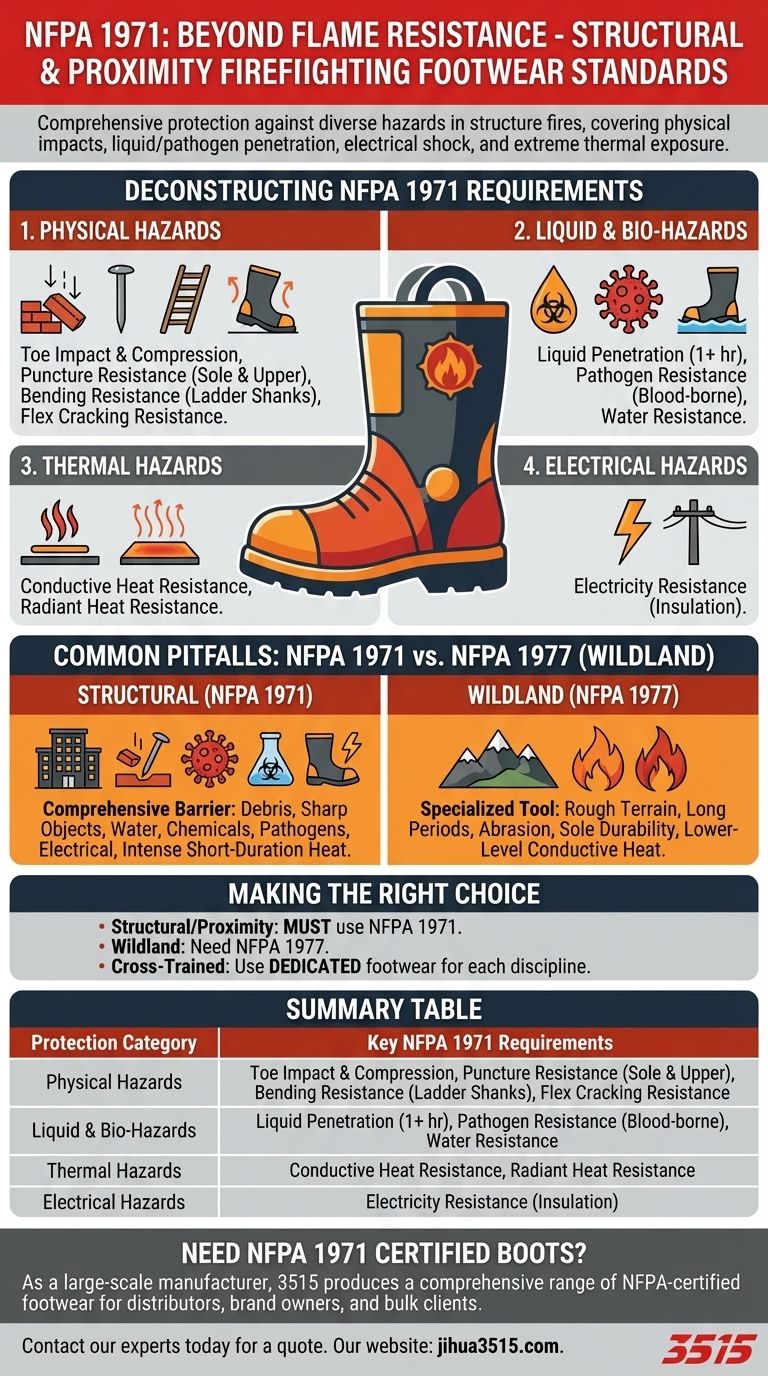

Deconstructing the NFPA 1971 Footwear Requirements

The NFPA 1971 standard is designed to ensure boots can withstand the full spectrum of dangers present during structural and proximity firefighting operations. The requirements can be broken down by the type of protection they provide.

Protection from Physical Hazards

This category focuses on shielding the firefighter from punctures, crushing injuries, and the physical strain of the job.

- Toe Impact and Compression Resistance: The boot must protect the toes from injury caused by falling objects and compression, functionally equivalent to a standard safety toe.

- Puncture Resistance: A protective plate is required in the sole and heel, but the standard also mandates puncture resistance in the upper portion of the boot to defend against nails, glass, and other sharp debris.

- Bending Resistance (Ladder Shanks): The boot's sole must contain a rigid shank that provides support and reduces fatigue when standing on ladder rungs for extended periods.

- Flex Cracking Resistance: The boot must endure repeated flexing without any signs of cracking or damage to the puncture-resistance device, ensuring long-term durability.

Protection from Liquid and Bio-Hazards

Fire scenes often involve water and other hazardous fluids, requiring the boot to be a perfect barrier.

- Liquid Penetration Resistance: The footwear must prevent any liquid from penetrating for a minimum of one hour, protecting against water, chemical spills, and contaminated runoff.

- Pathogen Resistance: The boot is tested for its ability to protect against liquid or blood-borne pathogens, a critical feature during rescue operations or when navigating hazardous environments.

- Water Resistance: This general requirement ensures the boot keeps the foot dry, which is essential for comfort, function, and preventing injuries like blisters.

Protection from Thermal Hazards

While all firefighting gear must resist heat, NFPA 1971 specifies two critical tests for footwear.

- Conductive Heat Resistance: This test simulates standing on a hot surface, ensuring the inside sole temperature does not rise to a level that would cause injury.

- Radiant Heat Resistance: This test evaluates the boot's ability to protect the firefighter from the intense heat radiating from a nearby fire, which is a primary hazard in proximity firefighting.

Protection from Electrical Hazards

Fallen power lines and compromised electrical systems are common dangers inside a damaged structure.

- Electricity Resistance: The boot must pass an electrical insulation test to provide a degree of protection against accidental contact with energized circuits.

Common Pitfalls: Confusing NFPA 1971 with NFPA 1977

A frequent point of confusion is the difference between boots made for structural firefighting (NFPA 1971) and those for wildland firefighting (NFPA 1977). The standards are entirely different because the environments and risks are not the same.

The Focus of Structural Boots (NFPA 1971)

Structural boots are a comprehensive barrier. They are built to defend against the hazards of a building: falling debris, sharp objects on the floor, water, chemicals, blood-borne pathogens, and electrical current. The thermal protection is geared toward intense, short-duration heat.

The Focus of Wildland Boots (NFPA 1977)

Wildland boots (NFPA 1977) are a specialized tool for navigating rough terrain for long periods. They prioritize abrasion resistance, sole durability, and resistance to lower-level conductive heat (keeping the inside sole below 111°F) from hot ground. They do not require the pathogen, chemical, or electrical protection mandated by NFPA 1971.

Making the Right Choice for Your Role

Understanding these standards is key to ensuring you have the correct personal protective equipment for your specific operational environment.

- If your primary focus is structural or proximity firefighting: Your boots must be certified to NFPA 1971 to provide the necessary protection against the full range of chemical, pathogen, electrical, and impact hazards found inside buildings.

- If your primary focus is wildland firefighting: You need boots certified to NFPA 1977, which are specifically designed for heat resistance over long durations, durability on rugged terrain, and abrasion resistance.

- If your role involves both (cross-trained): You must use dedicated, certified footwear for each specific discipline, as the protection standards are not interchangeable and are designed for fundamentally different risks.

Selecting footwear that precisely matches the NFPA standard for your operational environment is a critical foundation of personal safety.

Summary Table:

| Protection Category | Key NFPA 1971 Requirements |

|---|---|

| Physical Hazards | Toe impact/compression resistance, puncture resistance (sole & upper), ladder shank, flex cracking resistance |

| Liquid & Bio-Hazards | Liquid penetration resistance (1+ hour), pathogen resistance (blood-borne), water resistance |

| Thermal Hazards | Conductive heat resistance (hot surfaces), radiant heat resistance (fire proximity) |

| Electrical Hazards | Electricity resistance (insulation against energized circuits) |

Need NFPA 1971 Certified Structural Firefighting Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and boots, ensuring your team has the precise, reliable protection required for structural and proximity firefighting.

Contact our experts today to discuss your specific requirements and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What should one consider when choosing packer boots? Key Features for Stability & Durability

- What is Stitch-down Construction in work boots? Discover the Ultimate Durability and Stability

- How is all-around comfort achieved in western boots? Discover the Integrated Comfort System

- How are PVC work boots typically manufactured? Discover the Efficient Injection Molding Process

- What factors should be considered when choosing between PVC and rubber boots? A Guide to Durability vs. Cost

- What historical factors affected engineer boot production? From WWII Workwear to Rebel Icon

- What are the common materials used for the upper part of work boots? Choose the Right Protection

- What customization options are available for moc toe boots? Build the Perfect Boot for Your Needs