Beyond basic waterproofing, modern rubber and PVC work boots are engineered with a range of advanced safety features designed to protect against specific industrial hazards. These enhancements include integrated safety toes for impact protection, certified chemical resistance for handling hazardous materials, electrical hazard ratings to prevent shock, and specially designed outsoles for heat and slip resistance.

The primary value of rubber and PVC boots has evolved from simple water protection to providing highly specialized defense against chemical, electrical, and physical threats. Understanding these specific features is critical for matching the right boot to the unique risks of your work environment.

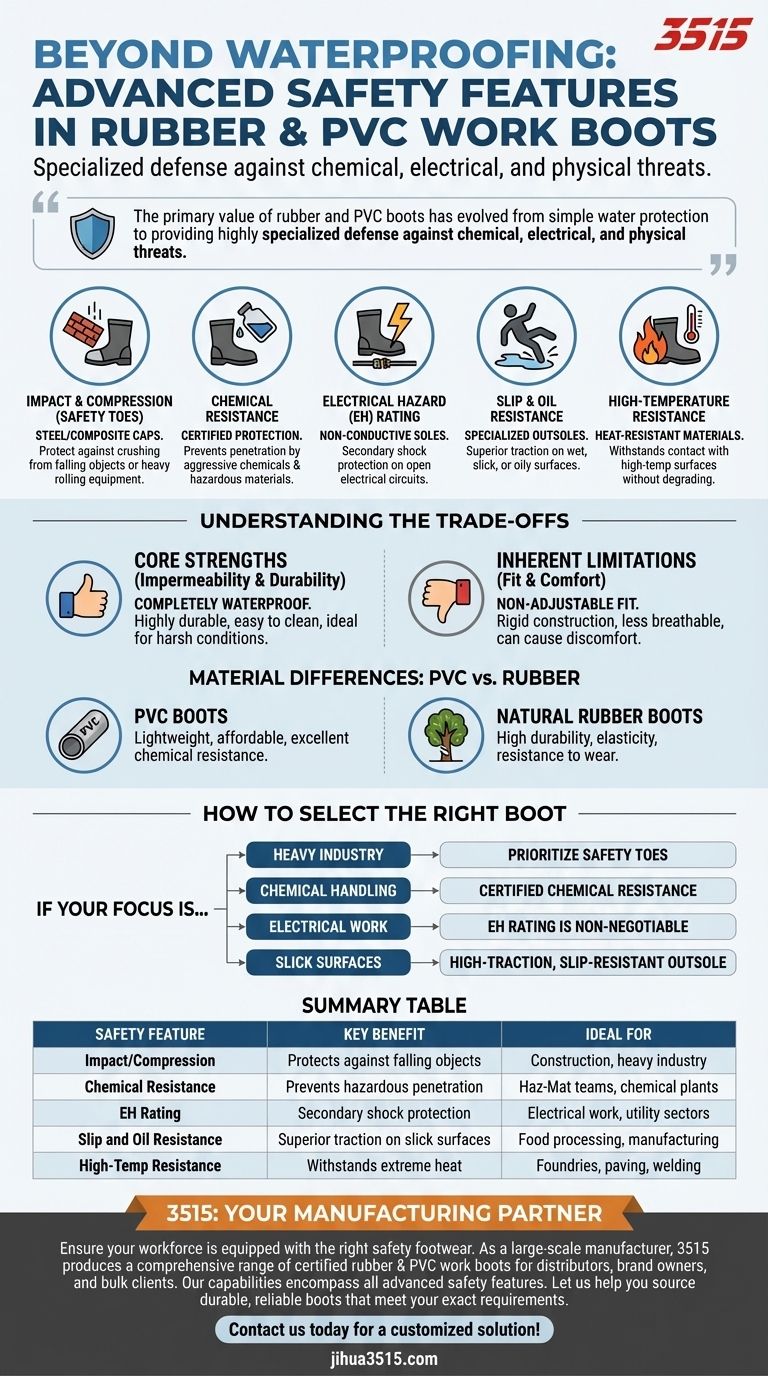

Beyond Waterproofing: A Breakdown of Key Safety Features

While their impervious nature is their defining characteristic, specialized rubber and PVC boots incorporate technology found in the most advanced safety footwear.

Impact and Compression Protection (Safety Toes)

Many boots feature steel or composite toe caps built directly into the footwear.

These components are designed to protect the foot from a crushing injury due to falling objects (impact resistance) or heavy rolling equipment (compression resistance).

Chemical and Hazardous Material Resistance

While the base materials offer some protection, many boots are specifically certified as chemical-resistant.

This certification ensures they can prevent penetration by a range of aggressive or harmful chemicals, making them essential for Haz-Mat teams and industrial plant workers.

Electrical Hazard (EH) Protection

Certain boots carry an Electrical Hazard (EH) rating.

These boots are constructed with non-conductive, shock-resistant soles and heels. They are designed to provide a secondary source of protection on surfaces where a worker could be exposed to open electrical circuits.

Slip and Oil Resistance

The outsole is a critical safety component. High-quality boots use specialized rubber compounds and tread patterns to provide superior traction.

This design delivers crucial slip resistance on wet, slick, or oily surfaces, a common hazard in many industrial settings.

High-Temperature Resistance

For environments with extreme heat, such as paving or foundry work, some boots are made with heat-resistant materials or outsoles.

These are engineered to withstand contact with high-temperature surfaces without melting or degrading, protecting the wearer from burns.

Understanding the Trade-offs

Choosing a rubber or PVC boot means accepting a specific set of advantages and limitations.

The Core Strengths: Impermeability and Durability

The fundamental advantage of these materials is that they are completely waterproof and non-absorbent.

This makes them highly durable, easy to clean and decontaminate, and ideal for harsh, wet, or messy conditions.

The Inherent Limitations: Fit and Comfort

The rigid, molded construction means the fit cannot be adjusted with laces.

This can make the boots feel cumbersome for extensive walking and can lead to a lack of breathability, causing discomfort during long shifts.

Material Differences: PVC vs. Rubber

PVC boots are typically more lightweight, affordable, and offer excellent protection against many chemicals.

Natural rubber boots are often prized for their high durability, elasticity, and resistance to wear and tear in rugged conditions.

How to Select the Right Boot for Your Hazard

Your choice should be dictated entirely by the specific risks you face on the job.

- If your primary focus is heavy industry or construction: Prioritize boots with certified steel or composite safety toes for impact protection.

- If your primary focus is chemical handling or Haz-Mat response: Look for boots with an explicit chemical-resistance certification, not just general waterproofing.

- If your primary focus is electrical work: A certified Electrical Hazard (EH) rating is a non-negotiable safety requirement.

- If your primary focus is working on slick or oily surfaces: Ensure the boot has a high-traction, slip-resistant outsole designed for those specific conditions.

Ultimately, selecting the correct protective footwear is a critical decision that directly impacts your personal safety.

Summary Table:

| Safety Feature | Key Benefit | Ideal For |

|---|---|---|

| Impact/Compression Protection (Safety Toes) | Protects against falling objects and crushing injuries | Construction, heavy industry |

| Chemical Resistance | Prevents penetration by hazardous materials | Haz-Mat teams, chemical plants |

| Electrical Hazard (EH) Rating | Provides secondary protection against electrical shocks | Electrical work, utility sectors |

| Slip and Oil Resistance | Superior traction on wet, slick, or oily surfaces | Food processing, manufacturing |

| High-Temperature Resistance | Withstands extreme heat without degrading | Foundries, paving, welding |

Ensure your workforce is equipped with the right safety footwear for their specific hazards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified rubber and PVC work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, including models with advanced features like steel toes, EH ratings, and chemical-resistant certifications. Let us help you source durable, reliable boots that meet your exact safety requirements. Contact us today for a customized solution!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- Which occupations typically prefer composite toe boots? Lightweight, Non-Conductive Safety for Electricians & Engineers

- What features should workers on slick floors look for in work boots? Maximize Safety & Stability

- How do insulated boots provide long-term health benefits? Prevent Nerve Damage & Frostbite

- What are the key features of workwear boots? A Guide to Certified Safety and Durability

- How did engineer boots transition from workwear to fashion? From Locomotive to Runway

- What is a recommended style for cowboy boots? Find Your Perfect Fit for Style & Function

- What are the drawbacks of using bike-specific boots with cleats in cold weather? Stay Warm & Safe

- What are the key characteristics of wildland firefighter boots? Essential Gear for Extreme Conditions