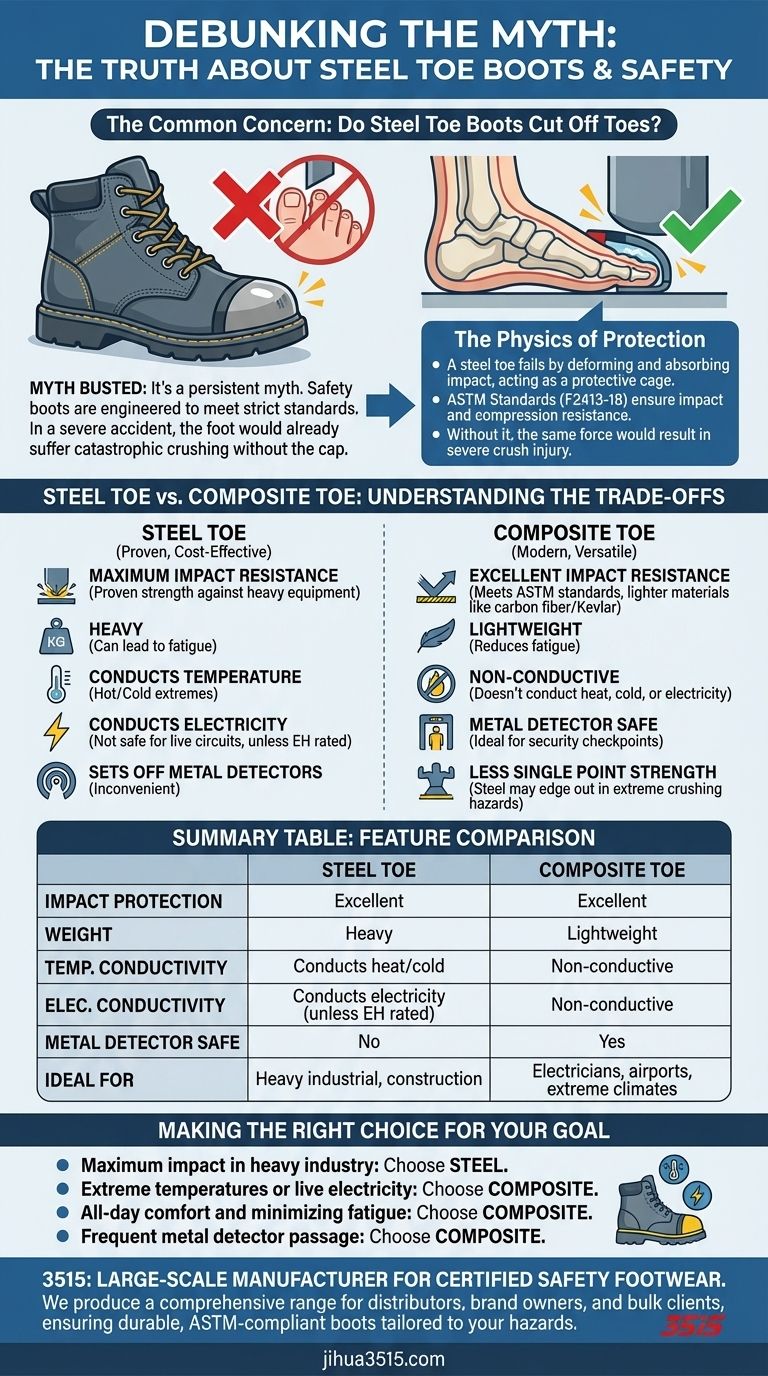

Let's address this common concern directly. The idea that a steel toe cap can curl and amputate your toes is a persistent myth. Safety boots are engineered to meet strict standards, requiring them to withstand immense impact and compression forces. In an accident severe enough to compromise the steel cap, the foot would have already sustained a catastrophic crushing injury without that protection in place.

The concern over steel toes causing amputation is a myth. The real question is not whether steel toes are safe, but whether their specific trade-offs—like weight and conductivity—make them the right choice for your specific work environment compared to modern alternatives.

Deconstructing the Myth: The Physics of Protection

The core function of a safety toe is to shield you from crushing and impact hazards. Understanding how they are designed and tested reveals why the amputation myth is unfounded.

How a Steel Toe Fails

For a steel toe to "cut" anything, the cap would have to fail, bend, and be pressed down with extreme force. The forces involved in such a scenario are massive, far exceeding what the human foot could withstand on its own.

The Role of ASTM Standards

Protective footwear sold in the United States must meet standards set by the American Society for Testing and Materials (ASTM F2413-18). These standards specify the exact requirements for impact and compression resistance. A boot only earns its rating after proving it can protect the wearer's toes from a designated force, ensuring the cap will not fail under predictable workplace hazards.

The Real-World Outcome

In a real-world incident involving extreme force, the steel toe cap is designed to deform in a way that absorbs and distributes the impact. It acts as a protective cage. Without it, the same force would result in a severe crush injury, which is precisely what the boot is designed to prevent.

Understanding the Trade-offs of Steel

While steel toes are exceptionally safe from a protection standpoint, they are an older technology with distinct characteristics. Choosing the right boot means understanding these practical trade-offs.

Advantage: Maximum Impact Resistance

Steel offers robust, trusted protection against heavy equipment and falling objects. It's a proven material for heavy-duty industrial and construction tasks where the risk of severe impact is high.

Advantage: Cost-Effectiveness

Generally, steel toe boots are less expensive than their composite or alloy counterparts, offering a high level of protection for a lower initial investment.

Disadvantage: Weight and Fatigue

Steel is heavy. The added weight and bulk of steel toe boots can lead to greater fatigue over a long workday compared to lighter alternatives.

Disadvantage: Thermal and Electrical Conductivity

Steel readily conducts temperature, meaning the toe cap can become very cold in winter or hot in summer. More importantly, steel conducts electricity, making standard steel toe boots completely unsuitable for electricians or those working around live circuits unless they have a specific Electrical Hazard (EH) rating.

The Modern Alternative: Composite Toes

Much of the discussion around steel's disadvantages has led to the rise of composite toe boots, which solve many of steel's inherent problems.

What Is a Composite Toe?

A composite toe is made from non-metal materials like carbon fiber, plastic, or Kevlar. They are engineered to meet the same ASTM safety standards as steel toes but with a different set of properties.

Key Advantages of Composite

Composite toes are significantly lighter than steel, do not conduct heat, cold, or electricity, and will not set off metal detectors. This makes them a superior choice for a wide range of professions, from electricians to airport workers.

Where Steel Still Has an Edge

While composite technology has advanced, steel can sometimes withstand a higher single point of impact. For environments with extreme crushing hazards, some professionals still prefer the proven strength of steel.

Making the Right Choice for Your Goal

Your ideal safety boot depends entirely on the hazards and demands of your job.

- If your primary focus is maximum impact protection in a heavy industrial setting: Steel toes offer proven, cost-effective strength.

- If your primary focus is working in extreme temperatures or around live electricity: Composite toes are the superior and safer choice due to their non-conductive properties.

- If your primary focus is all-day comfort and minimizing fatigue: The lighter weight of composite toe boots will make a significant difference over a long shift.

- If your primary focus is passing through metal detectors frequently: Composite toes are a necessity to avoid daily hassle and comply with security requirements.

Ultimately, choosing modern safety footwear is about matching the right material to the specific risks you face each day.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Impact Protection | Excellent (Proven strength) | Excellent (Meets ASTM standards) |

| Weight | Heavy | Lightweight |

| Temperature Conductivity | Conducts heat/cold | Non-conductive |

| Electrical Conductivity | Conducts electricity (unless EH rated) | Non-conductive |

| Metal Detector Safe | No | Yes |

| Ideal For | Heavy industrial, construction | Electricians, airports, extreme climates |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the proven strength of steel toes or the modern advantages of composite materials, our production capabilities ensure you get durable, ASTM-compliant boots tailored to your specific hazards.

Let's protect your team with the right equipment. Contact our experts today to discuss your needs and get a quote.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are Western work boots? The Ultimate Guide to Safety and Style

- What should be considered when choosing a cleaner and conditioner for leather work boots? Ensure Long-Term Durability

- What are signs that work boots need replacement? Don't Risk Your Safety on Worn-Out Footwear

- How do oilfield boots ensure comfort during long shifts? The Ultimate Guide to All-Day Support

- What additional protection do metatarsal boots provide? Achieve Full Instep Safety from Impact and Compression

- What is the purpose of safety toe boots? Ultimate Protection for Your Work Environment

- What structural features are important in Wellington work boots? Ensure Slip-On Safety and Support

- How can water enter work boots despite water resistance? The 3 Main Entry Points Explained