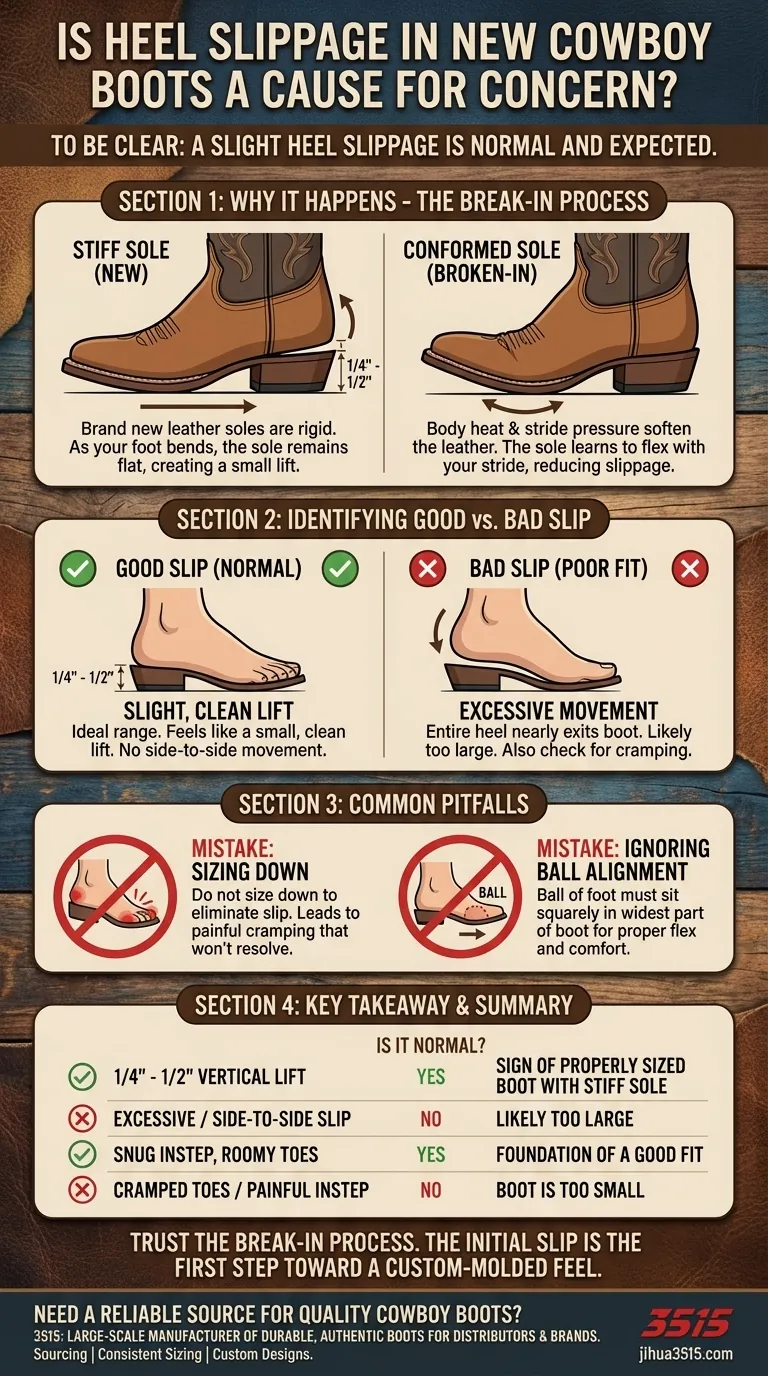

To be clear, a slight heel slippage in new cowboy boots is not a cause for concern. In fact, it is a perfectly normal and expected part of the break-in process. This initial movement is a feature, not a flaw, indicating that the boot's rigid structure has not yet conformed to the unique shape and flex of your foot.

The core issue isn't the presence of slip, but its degree. A small lift is a sign of a properly sized boot with a stiff new sole, whereas excessive movement points to an incorrect fit.

Why Heel Slip Is a Normal Part of the Break-In Process

Understanding the construction of a traditional cowboy boot is key to understanding why your heel moves when the boot is new.

The Role of a Stiff Leather Sole

Brand new cowboy boots, especially those with high-quality leather soles, are very rigid.

When you walk, your foot bends, but the stiff sole remains flat on the ground. This difference in movement creates a small gap, causing your heel to lift slightly inside the boot.

How the Boot Conforms to Your Foot

As you wear the boots, your body heat and the pressure of your stride slowly soften the leather.

The sole will begin to flex at the ball of your foot, learning to move with your stride instead of against it. This drastically reduces the initial slippage.

The Importance of the Instep

A cowboy boot is designed to get its primary grip over your instep (the top of your foot).

This area should feel snug from the very beginning, like a firm handshake. It's this snugness that ultimately holds your foot securely in place once the rest of the boot breaks in.

Identifying Good Slip vs. a Poor Fit

While some slip is good, it's crucial to distinguish it from the signs of a boot that is simply the wrong size.

The Acceptable Range

The ideal amount of slippage is between a quarter and a half inch.

It should feel like a slight, clean lift as you step. It should not feel sloppy, and your heel should not move side-to-side.

Warning Signs of a Bad Fit

Excessive slippage where your entire heel nearly comes out of the boot means it's likely too large.

Conversely, pay close attention to the toe box. Your toes should have room to wiggle and should never feel cramped. The leather in the toe box will not stretch significantly.

A proper fit feels snug across the instep, allows for toe room, and has that characteristic minor slip in the heel.

Common Pitfalls to Avoid

Many first-time buyers make one critical mistake when trying to solve for initial heel slip.

The Mistake of Sizing Down

Do not size down to eliminate heel slip. This is the most common error.

Choosing a smaller size will lead to a cramped toe box and a painfully tight instep—problems that will not resolve with time. The minor heel slip will resolve itself; a cramped fit will not.

Ignoring the Ball of Your Foot

The widest part of your foot (the ball) should sit squarely in the widest part of the boot.

If it's too far forward or back, the boot's built-in flex point will not align with your foot's natural flex point, causing discomfort and improper wear.

Making the Right Choice for Your Foot

Focus on the overall feel, not just one isolated spot. A great fit is a balance of snugness and space in the right areas.

- If your primary focus is a perfect long-term fit: Prioritize a snug instep and adequate toe room, accepting that a half-inch of heel slip is part of the process.

- If you are concerned the boot is too big: Ensure the slippage is only vertical lift, not side-to-side motion, and that the ball of your foot is correctly positioned.

- If you are concerned the boot is too small: Check for any cramping in the toes; if they are touching the end or sides, the boot is too small, regardless of heel slip.

Trust the break-in process; that initial slip is the first step toward a boot that feels custom-molded to your foot.

Summary Table:

| Situation | Is It Normal? | Key Takeaway |

|---|---|---|

| 1/4" - 1/2" vertical lift | ✅ Yes | A sign of a properly sized boot with a stiff sole. It will decrease as the boot breaks in. |

| Excessive slip or side-to-side movement | ❌ No | Likely indicates the boot is too large. |

| Snug instep, roomy toe box | ✅ Yes | This is the foundation of a good fit. The instep holds your foot securely. |

| Cramped toes or painful instep | ❌ No | The boot is too small. These issues will not resolve with wear. |

Need a Reliable Source for Quality Cowboy Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and authentic cowboy boots for distributors, brand owners, and bulk clients. We understand the importance of proper construction and fit from the very first wear.

We can help you:

- Source high-quality boots built with the right materials for a correct break-in process.

- Ensure consistent sizing across large orders for your customers.

- Customize designs to meet your specific market needs.

Let's discuss your next order. Contact our team today to explore how our manufacturing expertise can benefit your business.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium Grain Leather Safety Boots for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How does the mirror software function improve production efficiency in automated shoe polishing? Halve Setup Time Now

- Why is the implementation of AI-driven monitoring systems significant for sustainable footwear production processes?

- What are the structural differences between specialized functional footwear and standard footwear? Key Gait Insights

- Why should alcohol and water sprays be avoided for boot stretching? They Cause Permanent Leather Damage

- What is the physical significance of integrating tri-axial accelerometers into smart insoles? Precise Gait Analysis

- What is the Overall Stability Index (OSI) in Footwear Research? Achieve Superior Balance & Safety

- In the study of landing buffer technologies, what value do pressure sensors provide? Optimize Footwear Injury Prevention

- What role do industrial treadmills play in footwear comfort evaluation? Mastering Scientific Testing Reliability