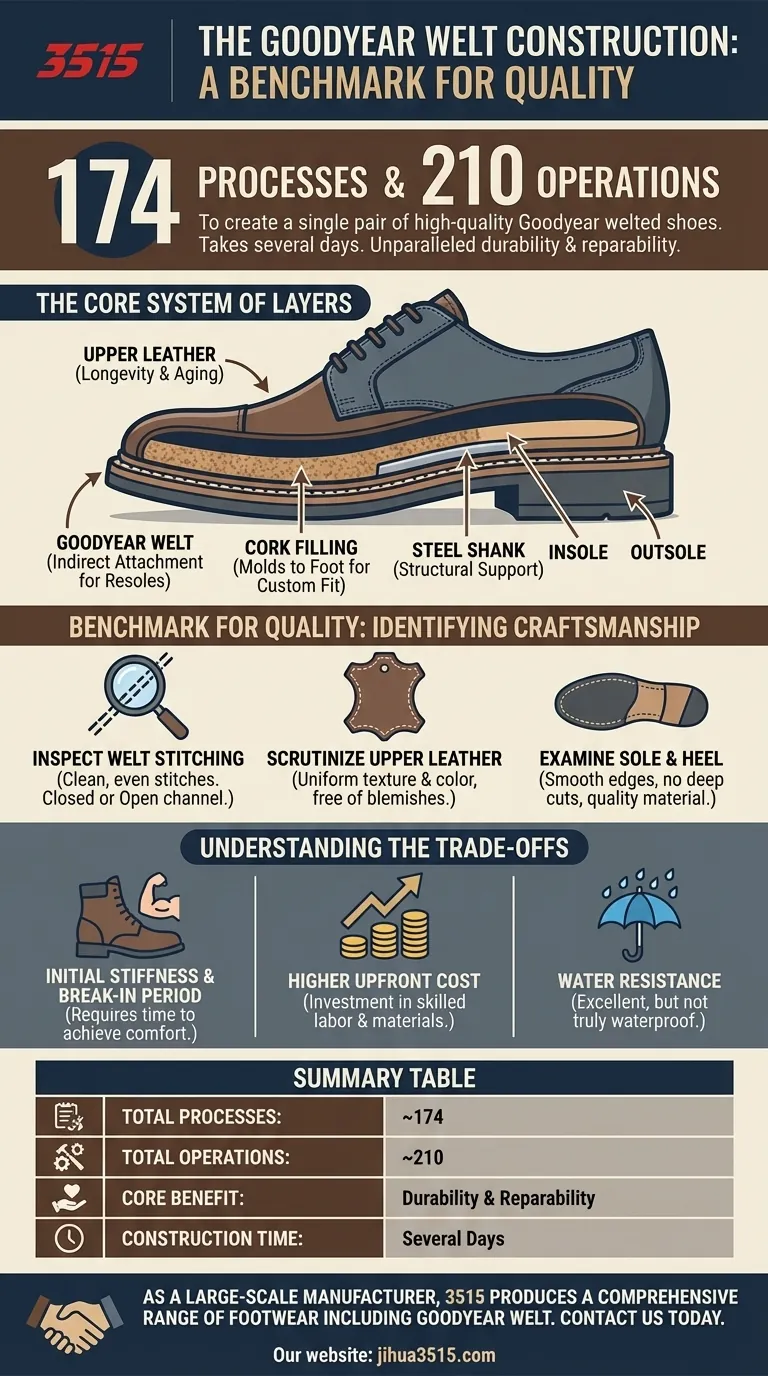

In short, creating a single pair of high-quality Goodyear welted shoes involves approximately 174 distinct processes and 210 separate operations. This highly specialized construction method requires immense skill and can take several days to complete, forming the bedrock of what defines truly durable and repairable footwear.

The sheer number of steps is less important than what they represent: a deliberate construction method designed for unparalleled durability, reparability, and a fit that customizes to your foot over time.

Why This Process is the Benchmark for Quality

The complexity of the Goodyear welt is not for show; it is a direct investment in the shoe's structure, comfort, and lifespan. Each stage contributes to the final product's signature characteristics.

The Core Principle: A System of Layers

The Goodyear welt is a strip of leather sewn around the bottom edge of the shoe's upper. This welt is then stitched to the sole.

This creates an indirect attachment, meaning the sole is not stitched directly into the insole and upper. This separation is the key to the shoe's most significant benefit: reparability.

The Engine of Comfort: Cork and Shank

Between the insole and the outsole, a cavity is filled with a layer of granulated cork. This cork filling slowly compresses and molds to the unique shape of your foot, creating a custom-like fit over time.

A steel shank is also embedded in the shoe's waist to provide structural support and maintain its shape, allowing the foot to move naturally without the shoe collapsing.

The Foundation of Longevity: High-Quality Leather

The construction method is designed to outlast the original sole. This is why high-quality upper leather is non-negotiable.

This leather is chosen for its ability to last for decades and improve with age. With proper care, the upper will remain in excellent condition through multiple resoles, justifying the initial investment.

How to Identify True Craftsmanship

Beyond knowing the process, you need to know what to look for. The execution of these steps is what separates a good shoe from a great one.

Inspect the Welt Stitching

The stitching that attaches the welt to the sole is a primary indicator of quality. Look for stitches that are clean, even, and consistent.

Some shoes feature a closed channel sole, where a flap of leather is cut, the stitching is done underneath, and the flap is glued back down for a seamless look. Others use an open channel, where the stitch is visible. An open channel makes it easier to inspect the quality, but a well-executed closed channel is a sign of high-end craftsmanship.

Scrutinize the Upper Leather

Examine the leather used for the upper part of the shoe. It should be uniform in its texture and color, without significant blemishes or deep imperfections. Quality leather is the visual and functional heart of the shoe.

Examine the Sole and Heel

Check the material quality of the sole and the heel block. There should be no deep cuts or gouges from the manufacturing process. The edges should be smoothly finished and polished.

Understanding the Trade-offs

No construction method is perfect for every situation. Objectivity requires acknowledging the inherent trade-offs of a Goodyear welt.

Initial Stiffness and Break-In Period

The durable, multi-layered construction that provides long-term support also results in initial stiffness. Goodyear welted shoes almost always require a break-in period before they achieve their renowned comfort.

Higher Upfront Cost

The skilled labor, time, and quality materials required for over 200 operations mean these shoes have a significantly higher initial price point compared to cemented or Blake-stitched footwear.

Water Resistance, Not Waterproofing

While the welt provides excellent water resistance, the stitched construction means it is not truly waterproof. Water can eventually penetrate the stitch holes in heavy rain or when submerged.

Making the Right Choice for Your Goal

The decision to invest in Goodyear welted shoes depends on your priorities.

- If your primary focus is long-term value: A Goodyear welt is the superior choice, as the ability to resole the shoe multiple times can give it a lifespan of decades, not years.

- If your primary focus is immediate comfort: Be prepared for a break-in period of several wears as the cork footbed and leather upper mold to your foot's unique shape.

- If your primary focus is assessing quality: Pay closest attention to the consistency of the welt stitching and the uniformity of the upper leather, as these are the clearest indicators of skilled craftsmanship.

Understanding the intricate process behind a Goodyear welt transforms you from a simple consumer into a knowledgeable owner.

Summary Table:

| Key Metric | Detail |

|---|---|

| Total Processes | ~174 |

| Total Operations | ~210 |

| Core Benefit | Unparalleled Durability & Reparability |

| Key Component | Leather Welt, Cork Filling, Steel Shank |

| Construction Time | Several Days |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the intricate Goodyear welt construction. Let us apply our expertise and manufacturing capacity to your next project. Contact us today to discuss how we can deliver the quality and durability your customers demand.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear

- How should dress shoes be maintained to prolong their lifespan? A Guide to Lasting Quality

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality