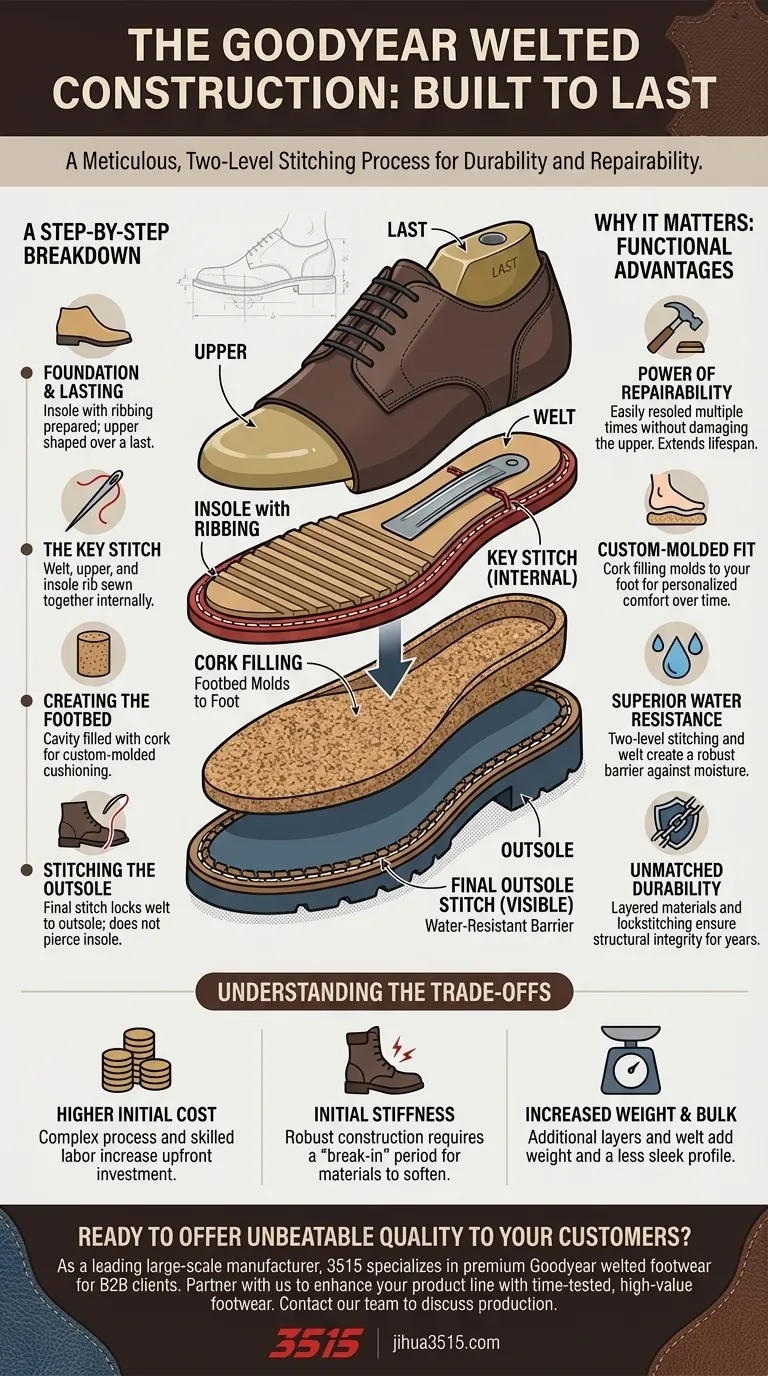

At its core, the Goodyear welt construction is a meticulous, two-level stitching process. First, a leather strip called a welt is stitched to the shoe's upper and a canvas rib on the insole. Then, in a separate stitch, this welt is attached to the outsole, creating an incredibly durable and easily repairable shoe. This method also creates a cavity between the insole and outsole, which is filled with cork for cushioning.

The true value of a Goodyear welt is not just its strength, but its design for longevity. It is the only mainstream construction method that allows a shoe to be resoled multiple times without compromising the structural integrity of the upper, fundamentally separating the part that wears out (the sole) from the part that molds to your foot (the upper).

A Step-by-Step Breakdown of the Goodyear Welt

The Goodyear welt process is renowned for its complexity, often involving over 150 distinct steps. However, the construction can be understood by focusing on a few critical stages that define its unique character and strength.

The Foundation: Insole and Ribbing

The entire shoe is built upon a carefully prepared insole. A canvas rib is cemented to its perimeter, creating the anchor point for the entire construction. A metal shank is often added at this stage for arch support and shape retention.

Lasting: Shaping the Upper

The leather upper is stretched and formed over a foot-shaped model called a "last." The edges of the upper are pulled down and secured to the insole, giving the shoe its definitive shape.

The Key Stitch: Attaching the Welt

This is the defining moment of the process. A specialized machine performs a lockstitch that sews the leather welt, the upper, and the insole rib together. This first stitch is internal and holds the core components of the shoe in place.

Creating the Footbed: The Cork Filling

The attachment of the welt creates a natural void between the insole and what will become the outsole. This cavity is filled with a layer of granulated cork or a similar filler material.

The Final Lock: Stitching the Outsole

The outsole is now placed on the bottom of the shoe. A final, highly visible, and robust stitch is sewn through the welt and the outsole, locking everything together. This stitch does not penetrate the insole, which is key to the shoe's water resistance.

Finishing: The Craftsman's Touch

The final stages involve trimming the sole and heel to their final shape, followed by meticulous cleaning, polishing, and quality inspection. These steps ensure the shoe meets high standards of both function and aesthetic.

Why This Complex Process Matters

The effort and expense of the Goodyear welt are justified by a clear set of functional advantages that are difficult to achieve with other construction methods.

The Power of Repairability

Because the outsole is stitched only to the welt, a cobbler can easily remove the old sole and stitch on a new one. This resoling process can be done repeatedly without ever disturbing the upper, vastly extending the life of the footwear.

A Custom-Molded Fit

The cork filling is not just for cushioning. Over time, your body heat and the pressure of your foot compress the cork, creating a footbed that is perfectly molded to the unique shape of your foot. This provides unparalleled, personalized comfort.

Superior Water Resistance

The two-level stitching system and the leather welt create a more robust barrier against water. Since the final outsole stitch doesn't pierce the insole, water has a much harder time seeping into the shoe from below.

Unmatched Durability

The combination of lockstitching, layered materials, and the welt itself creates a shoe that is incredibly strong and maintains its structural integrity over years of hard wear.

Understanding the Trade-offs

No construction method is perfect for every application. The benefits of a Goodyear welt come with inherent compromises that are important to acknowledge.

Higher Initial Cost

The complexity of the process, the specialized machinery, and the skilled labor required make Goodyear welted shoes significantly more expensive upfront than their cemented or Blake-stitched counterparts.

Initial Stiffness

The layered construction and robust materials result in a shoe that is often quite stiff out of the box. A "break-in" period is almost always required for the leather and cork to soften and conform to your foot.

Increased Weight and Bulk

The additional layers, including the welt and cork filling, add weight and create a less sleek profile. For users who prioritize a lightweight, minimalist feel, this can be a drawback.

Making the Right Choice for Your Footwear

Deciding if a Goodyear welt is right for you depends entirely on your priorities.

- If your primary focus is longevity and long-term value: The ability to resole the shoe makes the Goodyear welt the definitive choice for a buy-it-for-life investment.

- If your primary focus is a custom, supportive fit: The cork footbed that molds to your foot over time offers a level of personalized comfort that is hard to match.

- If your primary focus is immediate comfort and flexibility: Be prepared for a break-in period, or consider that another, more flexible construction might better suit your needs.

Ultimately, choosing a Goodyear welted shoe is an investment in a piece of footwear that is built not just to last, but to improve with age.

Summary Table:

| Aspect | Key Feature | Benefit |

|---|---|---|

| Construction | Two-level lockstitch with a leather welt | Creates a robust, water-resistant barrier |

| Repairability | Outsole stitched only to the welt | Allows for easy, repeated resoling |

| Comfort | Cork-filled cavity molds to the foot | Provides personalized, long-term comfort |

| Durability | Layered materials and robust stitching | Ensures structural integrity for years of wear |

| Considerations | Higher initial cost and break-in period | Investment in long-term value and performance |

Ready to Offer Unbeatable Quality to Your Customers?

As a leading large-scale manufacturer, 3515 specializes in producing premium Goodyear welted footwear for distributors, brand owners, and bulk clients. Our extensive production capabilities ensure you receive durable, repairable, and comfortable shoes and boots built to last.

Partner with us to:

- Enhance Your Product Line with time-tested, high-value footwear.

- Ensure Customer Satisfaction through superior comfort and longevity.

- Streamline Your Supply Chain with reliable, large-volume manufacturing.

Contact our team today to discuss your production needs and discover how 3515 can be your trusted footwear manufacturing partner.

Visual Guide

Related Products

- Heavy-Duty Goodyear Welted Pull-On Safety Rigger Boot

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

People Also Ask

- What historical events influenced the development of work boots and western boots? The Industrial Revolution & Frontier Expansion

- What are the advantages of the Powerwelt pull-on boots? Unmatched Convenience & Durability

- What are the pros and cons of heavy-duty wellington boots? Unmatched Protection vs. Key Trade-offs

- How long has Goodyear made shoes? Discover a Century of Rubber Expertise

- What purposes does oil-resistance serve in footwear? It's a Critical Safety Feature