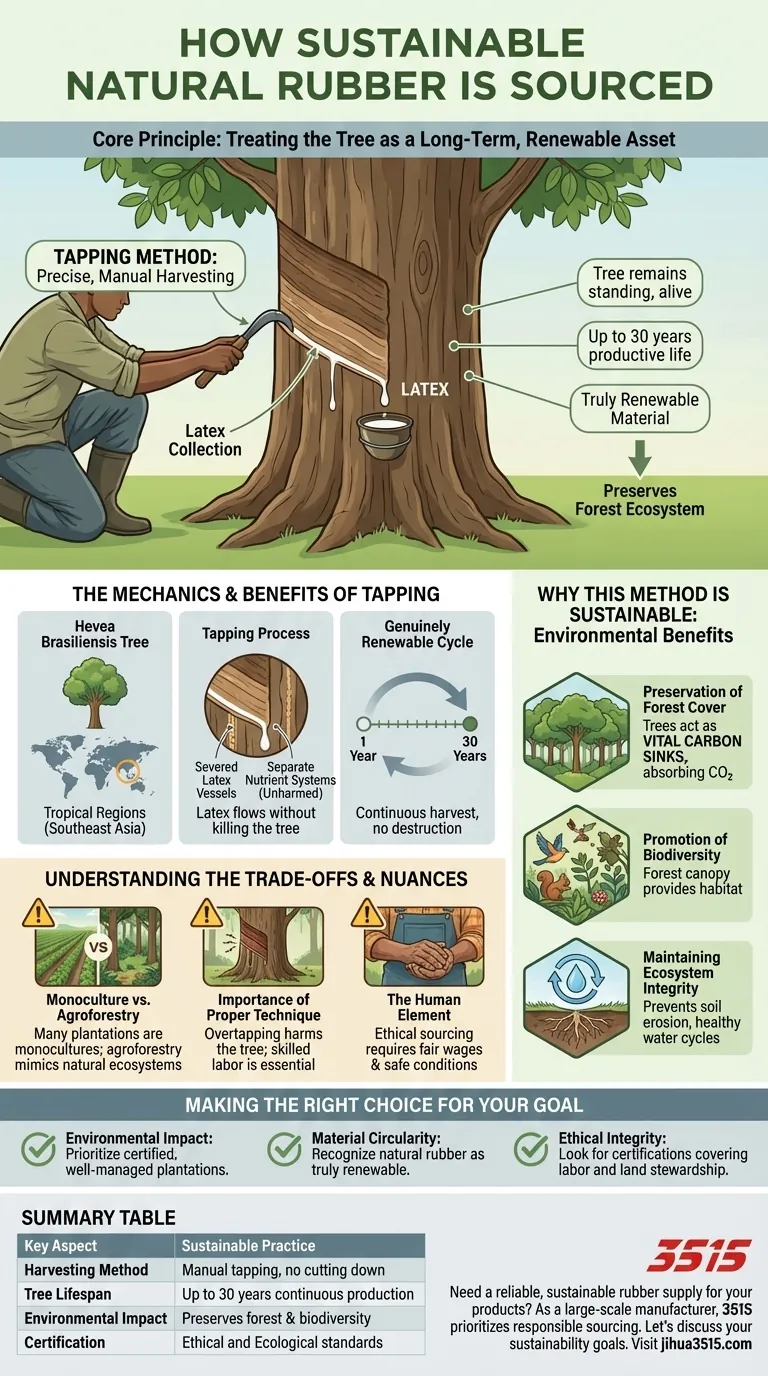

Sustainable natural rubber is sourced through a precise, manual harvesting method known as tapping. This process involves extracting a milky sap, called latex, from the Hevea Brasiliensis tree. Crucially, this is done without cutting the tree down, allowing it to continue living and producing for many years.

The core principle of sustainable rubber sourcing is treating the tree as a long-term, renewable asset. The tapping method preserves the tree's life, enabling a continuous harvest while maintaining the forest ecosystem it supports.

The Mechanics of Sustainable Tapping

To understand why this process is sustainable, we must first understand the mechanics of how latex is harvested. It is a system that has been refined to prioritize the long-term health of the tree.

The Hevea Brasiliensis Tree

Natural rubber originates from a single species: the Hevea Brasiliensis tree. While native to the Amazon, it is now cultivated primarily in the tropical regions of Southeast Asia.

The Tapping Process Explained

Tapping involves making a careful, shallow incision into the tree's bark at a downward angle. This cut severs the latex vessels, which are separate from the systems that transport water and nutrients, allowing the sap to flow out without killing the tree.

The latex then drips along the incision and is collected in a small cup. This process does not remove the tree from the ecosystem and allows it to continue its natural life cycle.

A Genuinely Renewable Cycle

A single rubber tree can be tapped for up to 30 years. This long productive life makes natural rubber a truly renewable material, unlike resources that require extraction or the destruction of the parent plant.

Why This Method Is Considered Sustainable

The benefits of tapping extend beyond the individual tree to the wider environment. It creates a system where economic value is directly tied to ecological preservation.

Preservation of Forest Cover

Because the trees are kept alive and productive, rubber plantations maintain forest cover. These standing trees act as vital carbon sinks, absorbing CO2 from the atmosphere and helping to mitigate climate change.

Promotion of Biodiversity

Well-managed rubber plantations can support a higher level of biodiversity compared to clear-cut land used for other forms of agriculture. The forest canopy provides a habitat for various species of plants and animals.

Maintaining Ecosystem Integrity

Keeping the trees in place preserves the local ecosystem. The root systems help prevent soil erosion, and the forest canopy contributes to healthy water cycles, creating a more stable and resilient environment.

Understanding the Trade-offs

While the tapping method is fundamentally sustainable, true sustainability depends on how the plantation is managed. Acknowledging the nuances is critical for a complete understanding.

Monoculture vs. Agroforestry

Many large plantations are monocultures, meaning they only grow rubber trees. This can limit biodiversity compared to a natural forest. More advanced sustainable models integrate rubber trees with other crops in an agroforestry system to better mimic a natural ecosystem.

The Importance of Proper Technique

The claim that tapping "doesn't harm the tree" is contingent on proper technique. Overtapping or cutting too deeply can stress the tree, reduce its lifespan, and make it susceptible to disease. Skilled labor is essential for true sustainability.

The Human Element

True sustainability must also account for social and economic factors. Ethical sourcing involves ensuring fair wages and safe working conditions for the tappers, many of whom are smallholder farmers who depend on rubber for their livelihood.

Making the Right Choice for Your Goal

The sustainability of natural rubber is not just a fact; it's a practice. How you apply this understanding depends on your specific priorities.

- If your primary focus is environmental impact: Prioritize rubber sourced from certified, well-managed plantations that function as carbon sinks and preserve local ecosystems.

- If your primary focus is material circularity: Recognize that natural rubber is a truly renewable resource, as the same tree can be tapped for decades, providing a continuous supply.

- If your primary focus is ethical integrity: Look beyond the tapping method itself to certifications that ensure fair labor practices and responsible land stewardship.

By understanding these principles, you can more accurately assess the sustainability of the natural rubber within your supply chain.

Summary Table:

| Key Aspect | Sustainable Practice |

|---|---|

| Harvesting Method | Manual tapping without cutting down the tree |

| Tree Lifespan | Up to 30 years of continuous latex production |

| Environmental Impact | Preserves forest cover and promotes biodiversity |

| Certification | Look for ethical and ecological certifications |

Need a reliable, sustainable rubber supply for your products?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we prioritize sustainable materials like responsibly sourced natural rubber to enhance your brand's environmental credentials.

Let's discuss how we can support your sustainability goals — contact us today to explore partnership opportunities!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What materials are used in snow boots and rain boots? A Guide to Waterproof Footwear

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability

- What are the characteristics of rubber as a rain boot material? Discover Its Durability & Flexibility