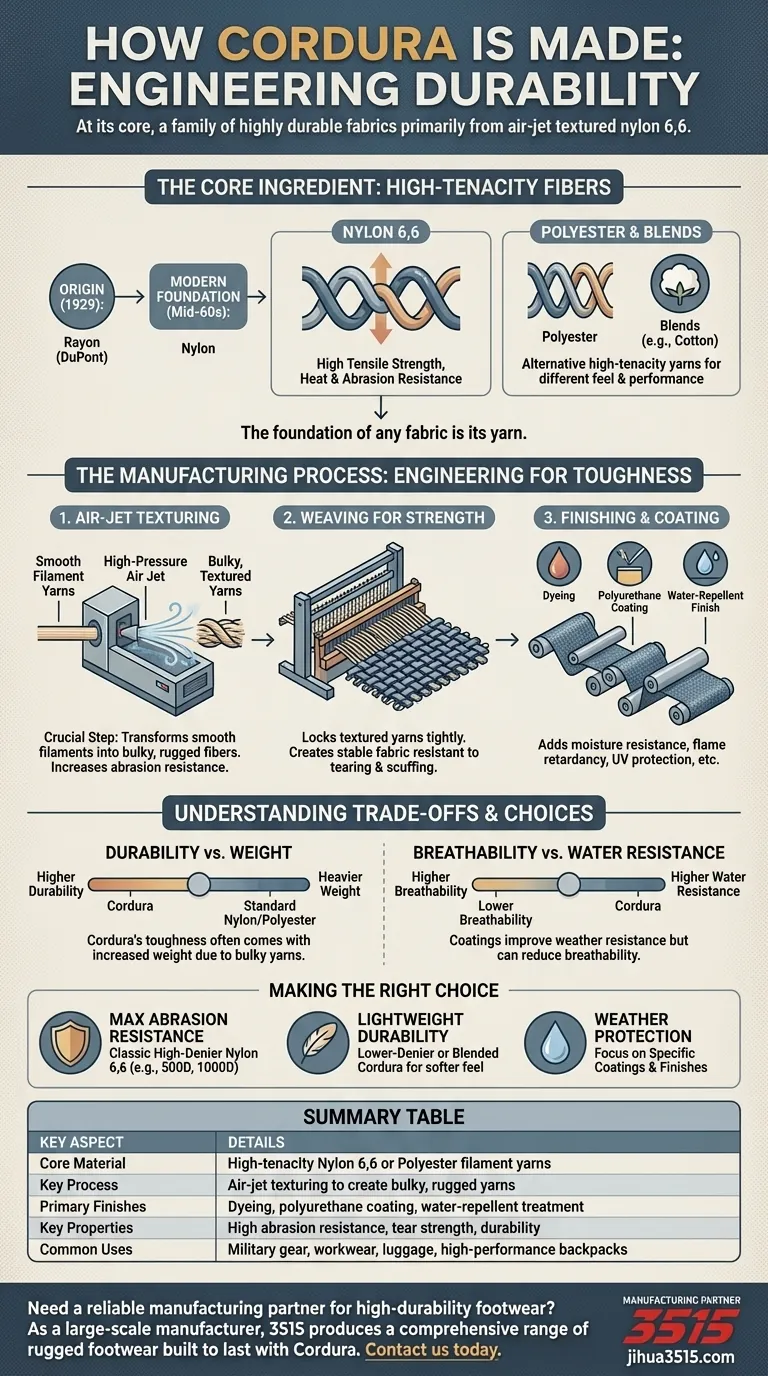

At its core, Cordura is a family of highly durable fabrics primarily made from high-tenacity, air-jet textured nylon 6,6 filament yarns. The manufacturing process involves weaving these specially textured yarns into a robust fabric, which is then dyed and treated with finishing coatings to enhance its resistance to abrasions, tears, and water. While nylon is the classic foundation, Cordura can also be based on polyester or blended with other fibers like cotton.

The legendary toughness of Cordura comes not just from the raw material—strong nylon fibers—but from a specific manufacturing process. The critical step is air-jet texturing, which transforms smooth, flat yarns into bulky, rugged fibers that are then woven to maximize durability.

The Core Ingredient: High-Tenacity Fibers

The foundation of any fabric is its yarn. Cordura's reputation for strength begins with the specific polymer fibers selected for its construction.

From Rayon to Nylon 6,6

Cordura was originally developed by DuPont in 1929 as a type of rayon. However, the fabric we know today was born in the mid-1960s when it was re-engineered using nylon, a move that dramatically increased its strength and resilience.

The Power of Nylon 6,6

The classic and most common material for Cordura is nylon 6,6. This specific type of synthetic polymer is known for its high tensile strength, durability, and resistance to heat and abrasion. These inherent qualities make it the ideal starting point for a rugged textile.

Polyester and Blended Alternatives

While nylon 6,6 is the benchmark, Cordura is a brand, not a single material. The name also applies to fabrics made from high-tenacity polyester yarns. In some cases, these core fibers are blended with materials like cotton to achieve a different feel, texture, or set of performance characteristics.

The Manufacturing Process: Engineering for Toughness

The raw material is only half the story. Cordura's signature characteristics are created through a multi-step manufacturing process designed to amplify the fabric's inherent strength.

Step 1: Air-Jet Texturing

This is the most crucial step. The smooth, flat filament yarns of nylon or polyester are hit with a high-pressure jet of air. This process tangles and loops the individual filaments, transforming the yarn from a smooth, silky strand into a much bulkier, textured yarn with a matte, canvas-like finish.

This texturing dramatically increases the fabric's resistance to abrasion. Instead of a single flat surface taking the brunt of friction, the thousands of tiny, looped fibers dissipate the force and resist wear.

Step 2: Weaving for Strength

The newly textured yarns are then woven together. The specific weave pattern, often a plain or basket weave, is chosen to lock the yarns tightly in place, creating a stable fabric that is highly resistant to tearing and scuffing.

Step 3: Finishing and Coating

After weaving, the raw fabric is dyed and treated with various finishes. A polyurethane coating and a water-repellent finish are common, providing resistance to moisture. Other treatments can be applied to add flame retardancy, UV resistance, and protection against mold or mildew.

Understanding the Trade-offs

No material is perfect for every application. To be a true expert, you must understand the limitations and considerations of working with Cordura.

Durability vs. Weight

Cordura's toughness often comes with a weight penalty. Compared to standard, non-textured nylon or polyester of the same thickness, Cordura is typically heavier due to the "bulked up" nature of its yarns.

Breathability Considerations

The same coatings that make Cordura highly water-repellent can also reduce its breathability. This is a classic trade-off in performance fabrics; increasing weather resistance often means trapping more moisture and heat from your body.

A Family of Fabrics, Not One Material

It's a common mistake to think of "Cordura" as a single fabric. The brand encompasses a wide range of textiles with different weights, fibers (nylon vs. polyester), and finishes. A lightweight Cordura used in a daypack will have very different properties than a heavy-duty version used for military gear.

Making the Right Choice for Your Needs

Understanding how Cordura is made allows you to select the right variant for your specific goal.

- If your primary focus is maximum abrasion resistance and tear strength: Choose classic, high-denier (e.g., 500D or 1000D) Cordura based on nylon 6,6.

- If your primary focus is lightweight durability for everyday use: Look for lower-denier Cordura fabrics or those blended with other fibers for a softer feel.

- If your primary focus is weather protection: Pay close attention to the specific coatings and finishes applied to the fabric, as this determines its performance against water and UV rays.

Ultimately, choosing the right material is about matching the engineered properties of the fabric to the demands of your application.

Summary Table:

| Key Aspect | Details |

|---|---|

| Core Material | High-tenacity Nylon 6,6 or Polyester filament yarns |

| Key Process | Air-jet texturing to create bulky, rugged yarns |

| Primary Finishes | Dyeing, polyurethane coating, water-repellent treatment |

| Key Properties | High abrasion resistance, tear strength, durability |

| Common Uses | Military gear, workwear, luggage, high-performance backpacks |

Need a reliable manufacturing partner for high-durability footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of rugged footwear built to last. Our expertise in durable materials like Cordura ensures your products meet the highest standards for abrasion resistance and tear strength—ideal for distributors, brand owners, and bulk clients.

Contact us today to discuss your production needs and leverage our capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What is the focus of the guide on calfskin shoe care? Preserve Your Investment with Simple Daily Habits

- Why is the standardized donning and doffing procedure essential for PPE? Master Safety Protocols for Maximum Protection

- What precautions should be taken when waterproofing shoes? Ensure Long-Lasting Protection for Your Footwear

- How do fluorinated resins function as a water-repellent? Master the Science of Liquid-Beading Surface Technology

- What are the main differences between paddock boots and tall boots? A Rider's Guide to Choosing Right

- Why is high-precision EEG used in footwear design? Measuring Ergonomic Comfort via Neural Data

- How does a Virtual Fitting Room contribute to reducing return risks for footwear? Cut Logistics Costs & Boost Trust

- Why are high-precision Brushless DC (BLDC) motors and load cells used for footwear testing? Achieve Objective Quality