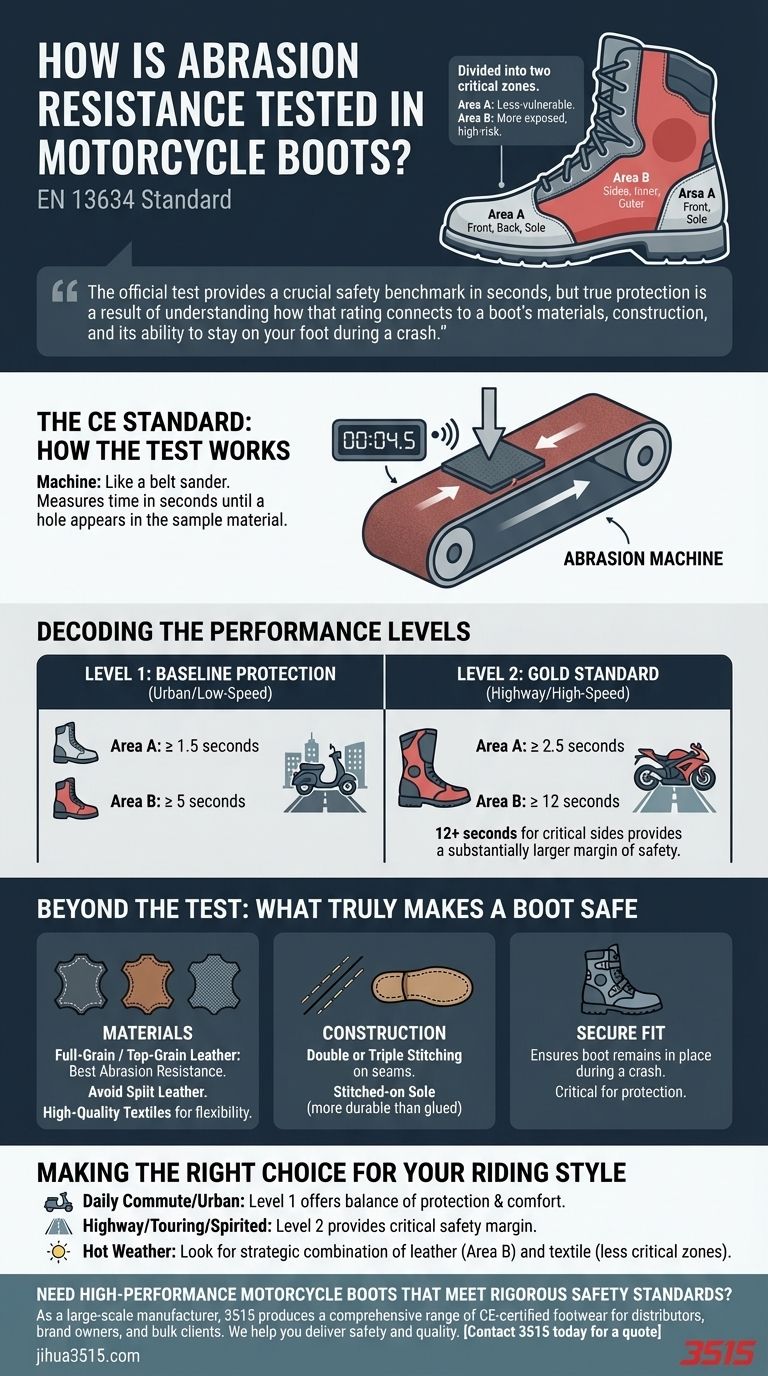

Motorcycle boot abrasion resistance is tested using a standardized laboratory method that divides the boot into two critical zones and measures how long the material can withstand friction before a hole is formed. The boot is separated into the less-vulnerable Area A (sole, front, and back) and the more exposed Area B (the sides), with each zone required to meet specific time-based durability standards.

The official test provides a crucial safety benchmark in seconds, but true protection is a result of understanding how that rating connects to a boot's materials, construction, and its ability to stay on your foot during a crash.

The CE Standard: How the Test Actually Works

To ensure motorcycle boots provide reliable protection, they are subjected to the EN 13634 standard. This test isn't a vague assessment; it's a precise, repeatable scientific measurement of a material's failure point.

Defining the Impact Zones

The test logically divides the boot into two areas based on the likelihood of prolonged contact with the road in a slide.

- Area A includes the sole and the very front and back of the boot. These areas are less likely to endure a long slide.

- Area B covers the sides of the boot. These are considered high-risk zones that will bear the brunt of the abrasion in most sliding accidents.

The Abrasion Machine

The test uses a specialized machine that functions much like a belt sander. A sample of the boot's outer material is cut out and subjected to a moving abrasive belt at a standardized speed and pressure.

Measuring Time to Failure

The machine runs continuously while a sensor monitors the material. The moment a hole appears through the sample, the timer stops. This duration, measured in seconds, is the material's abrasion resistance score.

Decoding the Performance Levels

The test results are categorized into two distinct levels of protection. The label on the boot will indicate which level it has achieved for abrasion resistance.

Level 1: The Baseline for Protection

A Level 1 rating is the minimum standard for certified motorcycle footwear. It signifies that the boot's materials survived for a specific duration.

- Area A: Must last at least 1.5 seconds.

- Area B: Must last at least 5 seconds.

This level of protection is suitable for lower-speed urban riding, where slides are typically shorter.

Level 2: The Gold Standard for Safety

Level 2 certification represents a significant increase in protection, making it the preferred standard for highway, track, or high-speed riding.

- Area A: Must last at least 2.5 seconds.

- Area B: Must last at least 12 seconds.

The jump from 5 to 12 seconds for the critical side-impact areas provides a substantially larger margin of safety in a prolonged slide.

Beyond the Test: What Truly Makes a Boot Safe

The CE rating is a critical data point, but it's only one part of the overall safety equation. The materials and construction of the boot determine its real-world performance.

The Critical Role of Materials

Not all materials are created equal. Full-grain or top-grain leather consistently provides the best abrasion resistance. Avoid split leather, which is ineffective in a crash. Modern textiles can offer excellent breathability and flexibility, but they must be high-quality, abrasion-resistant fabrics to be protective.

Construction is Non-Negotiable

The world's best material is useless if the boot falls apart on impact. Look for double or triple stitching on all seams. A stitched-on sole is also far more durable and less likely to be torn off than one that is simply glued.

The Importance of a Secure Fit

A boot can only protect you if it stays on your foot. A proper, secure fit ensures that in the violent tumbling of an accident, your boot remains in place to do its job.

Understanding the Trade-offs

Choosing the right boot involves balancing competing factors. There is no single "best" boot, only the best boot for your specific needs.

Protection vs. Comfort

Generally, a higher level of protection comes with trade-offs. A Level 2 boot made of thick leather will be heavier, stiffer, and less breathable than a lightweight, textile-based Level 1 boot.

The Limits of the Test

The lab test is a controlled simulation of one specific type of event: abrasion. It does not measure a boot's resistance to cuts, punctures, or crushing impacts, which are covered by other tests within the same EN 13634 standard.

Making the Right Choice for Your Riding Style

Use the CE rating as your starting point to filter your options based on your primary use case.

- If your primary focus is daily commuting or low-speed urban riding: A certified Level 1 boot offers a great balance of essential protection, comfort, and affordability.

- If your primary focus is highway touring or spirited riding: Investing in a Level 2 rated boot provides a critical, non-negotiable margin of safety for higher-speed scenarios.

- If your primary focus is maximum breathability for hot weather: Look for boots that strategically combine durable leather in Area B with advanced textile panels in less critical zones.

Ultimately, understanding these ratings empowers you to choose gear that protects you not just by the numbers, but by its fundamental design.

Summary Table:

| CE Protection Level | Area A (Sole, Front, Back) | Area B (Critical Sides) | Key Takeaway |

|---|---|---|---|

| Level 1 | ≥ 1.5 seconds | ≥ 5 seconds | Suitable for urban and low-speed riding. |

| Level 2 | ≥ 2.5 seconds | ≥ 12 seconds | Recommended for highway, touring, and high-speed riding. |

Need High-Performance Motorcycle Boots That Meet Rigorous Safety Standards?

As a large-scale manufacturer, 3515 produces a comprehensive range of CE-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective motorcycle boots and shoes, engineered with the right materials and construction to meet or exceed EN 13634 standards.

We help you deliver safety and quality. Let's discuss your requirements for durable, reliable motorcycle boots.

Contact 3515 today for a quote

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the current safety footwear standard in Europe? Your Guide to EN ISO 20345

- What new optional features were introduced in EN ISO 20345:2022? SC & LG Enhance Your Safety Footwear

- How does defining specific friction interface models in FEA assist in predicting safety shoe toe cap failure modes?

- Why is a fuzzy logic model more effective for professional footwear assets? Modeling Gradual Wear with Precision

- When must employers pay for OSHA-approved safety shoes? Understand Your Legal Obligations

- How do etching-type acidic floor coatings improve the ground slip resistance for safety footwear? | Enhance Grip Performance

- What factors should be considered when selecting safety shoes for workers? Ensure Maximum Protection and Comfort

- How do high-quality safety shoes contribute to resource conservation? Maximize Longevity & Sustainable Efficiency