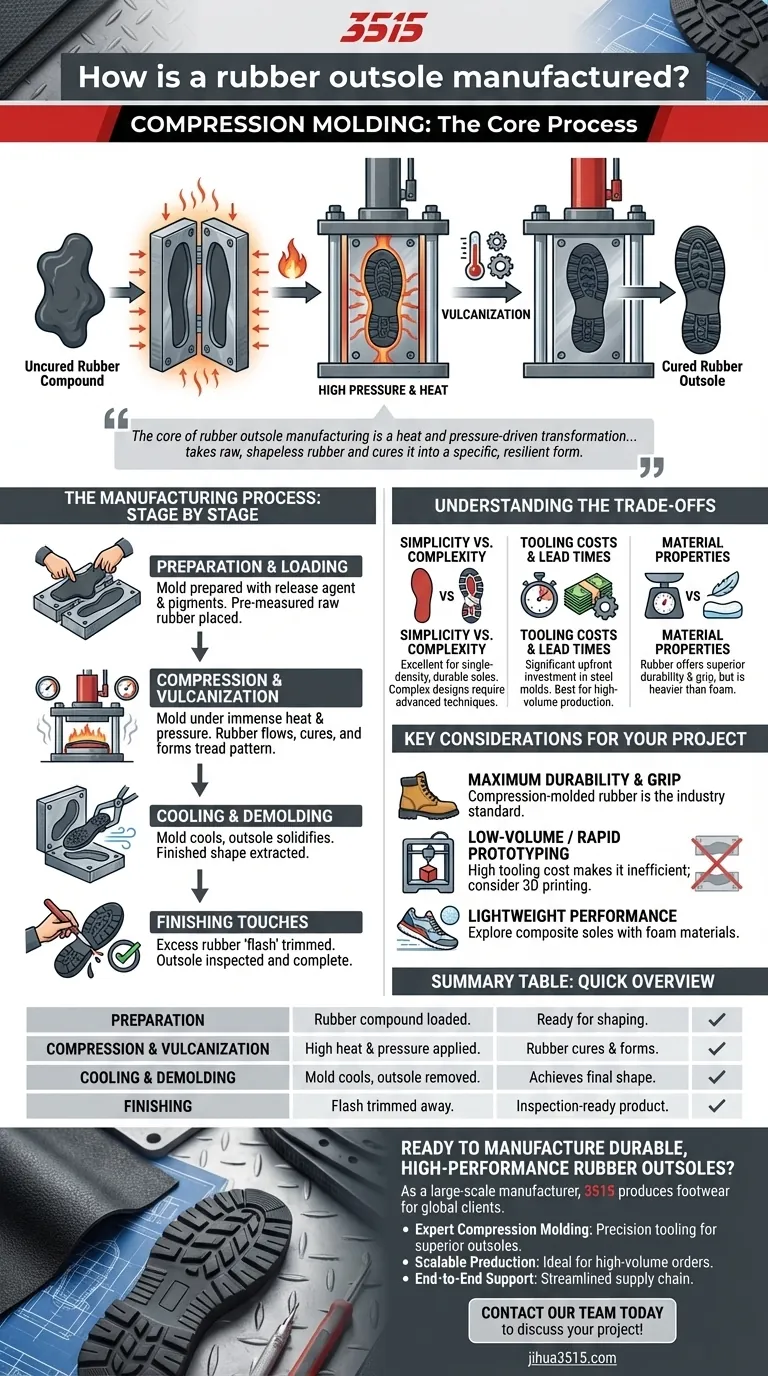

In short, a rubber outsole is manufactured by placing a pre-measured piece of uncured rubber compound into a heated metal mold, which is then compressed under high pressure. This process, known as compression molding, simultaneously forms the outsole's shape and vulcanizes the rubber, transforming it from a soft, pliable material into a durable, finished product. After cooling, excess rubber is trimmed away.

The core of rubber outsole manufacturing is a heat and pressure-driven transformation. It’s a relatively straightforward but precise process that takes raw, shapeless rubber and cures it into a specific, resilient form designed for footwear.

The Manufacturing Process: From Raw Material to Finished Product

To understand how a rubber outsole is made, it's best to break the process down into its essential components and sequential stages. Each step builds upon the last to ensure the final product has the required shape, durability, and features.

The Essential Ingredients

Before production can begin, four key elements are required:

- The Sole Design: This is the digital or physical blueprint that dictates the tread pattern, thickness, and overall shape of the outsole.

- Metal Outsole Tooling (The Mold): A heavy-duty, two-part metal mold is engineered based on the sole design. This tooling is the heart of the operation, as it gives the rubber its final form.

- Rubber Compound: This isn't just pure rubber. It's a specific recipe of raw rubber mixed with various chemicals and pigments to achieve desired properties like color, durability, and grip.

- A Heated Hydraulic Press: This powerful machine applies the immense pressure and high heat necessary to shape and cure the rubber inside the mold.

Stage 1: Preparation and Loading

The first step involves preparing the mold and the material. The inside of the metal tooling is often sprayed with a release agent and prepared with any necessary color pigments specified by the design. A carefully measured, pre-cut piece of the raw rubber compound is then placed precisely into the bottom half of the mold.

Stage 2: Compression and Vulcanization

The loaded mold is closed and placed into the hydraulic press. The press applies thousands of pounds of pressure while simultaneously heating the mold to a specific temperature. This combination of intense heat and pressure forces the soft rubber to flow into every crevice of the mold, creating the intricate details of the tread pattern. The heat initiates vulcanization, a chemical process that cures the rubber, making it strong, elastic, and wear-resistant.

Stage 3: Cooling and Demolding

After a set amount of time in the press, the mold is removed and allowed to cool. Once cooled, the mold is opened, and the newly formed rubber outsole is carefully extracted. At this stage, the outsole has its final shape and properties but isn't quite finished.

Stage 4: Finishing Touches

The compression process often leaves a thin layer of excess rubber, called "flash," around the edges of the outsole where the two halves of the mold meet. This flash is meticulously trimmed off by hand or machine. After trimming and a final quality inspection, the outsole is complete and ready to be bonded to a shoe upper.

Understanding the Trade-offs

While compression molding for rubber outsoles is a reliable and time-tested method, it's important to understand its limitations.

Simplicity vs. Complexity

The process is excellent for producing durable, single-density outsoles. However, creating complex, multi-color designs within a single outsole requires intricate mold preparation and can be labor-intensive. More advanced techniques are often needed for highly detailed, multi-part sole units.

Tooling Costs and Lead Times

Creating the initial steel mold is a significant upfront investment in both time and money. This makes the process best suited for high-volume production runs where the cost per unit can be minimized. It is not cost-effective for small batches or rapid prototyping.

Material Properties

Rubber provides excellent durability and grip but can be heavier than alternative materials like EVA foam or polyurethane (PU). The choice to use a rubber outsole is often a deliberate balance between the need for resilience and the desire for a lightweight final product.

Key Considerations for Your Project

Choosing the right manufacturing approach depends entirely on your end goal.

- If your primary focus is maximum durability and grip: Compression-molded rubber is the industry standard for work boots, hiking shoes, and high-wear sneakers for good reason.

- If your primary focus is low-volume or rapid prototyping: The high cost of metal tooling makes this method inefficient; consider alternative methods like 3D printing or open-mold sampling for initial designs.

- If your primary focus is lightweight performance: You may need to explore composite soles that combine rubber in high-wear areas with lighter foam materials for cushioning.

Ultimately, understanding this fundamental manufacturing process empowers you to make more informed decisions about footwear design and production.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| Preparation | Rubber compound is pre-cut and loaded into a heated mold. | Material is ready for shaping. |

| Compression & Vulcanization | Mold is compressed under high pressure and heat. | Rubber flows into tread pattern and cures for durability. |

| Cooling & Demolding | Mold is cooled and the outsole is removed. | Outsole achieves its final shape and properties. |

| Finishing | Excess rubber (flash) is trimmed away. | A clean, inspection-ready product is completed. |

Ready to manufacture durable, high-performance rubber outsoles?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the quality and volume you need.

Partner with us to benefit from:

- Expert Compression Molding: Leverage our precision tooling and process expertise for superior outsoles.

- Scalable Production: Ideal for high-volume orders with consistent quality.

- End-to-End Support: From design to finished product, we streamline your supply chain.

Contact our team today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

People Also Ask

- What are the environmental benefits of rubber soles? Renewable, Durable & Sustainable

- Why is Crepe Rubber considered versatile for footwear soles? Lightweight, Flexible & Durable

- What are the main types of shoe soles? A Guide to Choosing the Right Material

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- How do footwear outsole design and ground contact area influence walking stability? Enhance Balance with Biomechanics

- How does insole production differ from outsole production? Key Differences in Shoe Manufacturing

- What are the disadvantages of rubber boots for hunting? Poor Breathability & Support Issues

- How do natural rubber soles contribute to footwear aesthetics? From Subtle Elegance to Robust Style