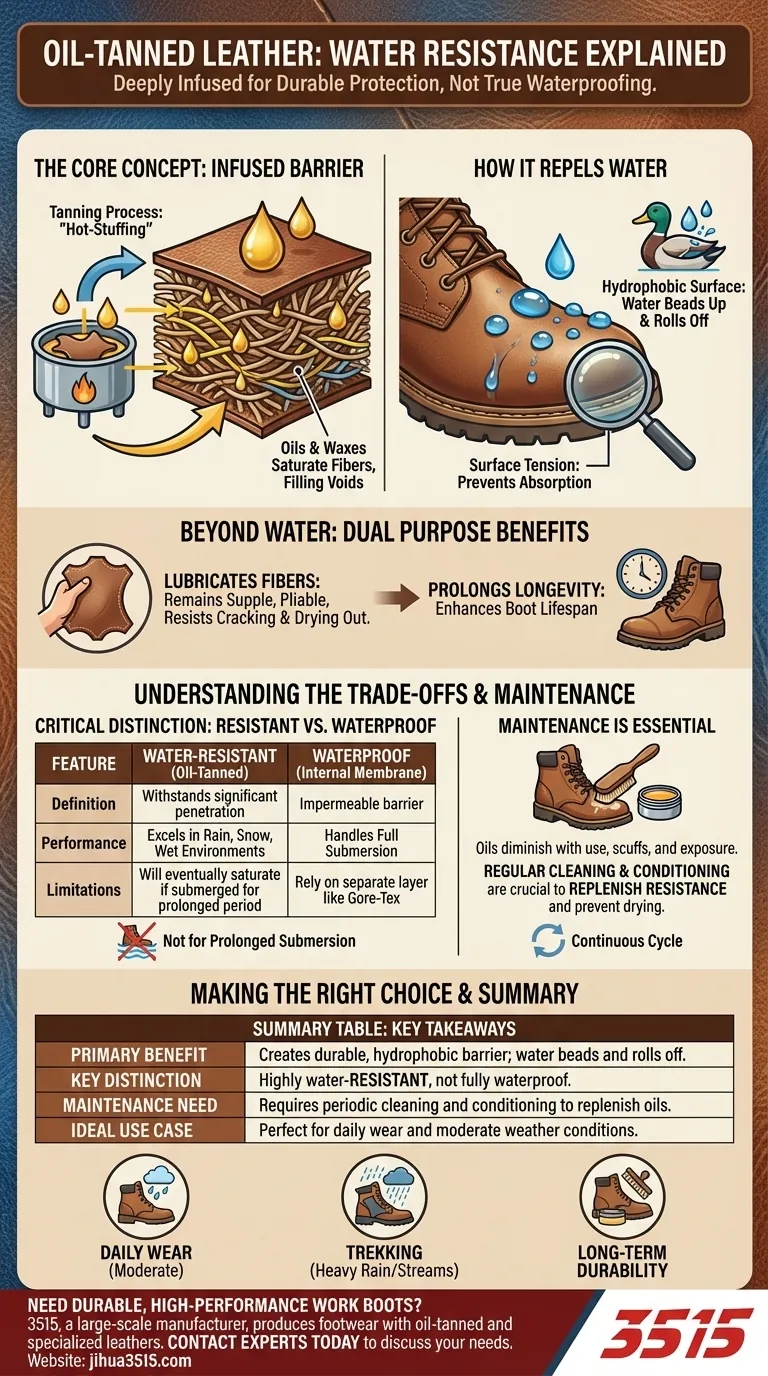

At its core, oil-tanned leather achieves water resistance by being deeply infused with a specific blend of oils and waxes during the tanning process. This treatment fundamentally changes the leather's properties, creating a durable barrier that causes water to bead up and roll off the surface rather than soaking into the fibers.

The key takeaway is that oil-tanned leather is highly water-resistant, not truly waterproof. Its effectiveness relies on oils embedded within the leather's structure, a barrier that is incredibly durable but requires periodic maintenance to remain effective against the elements.

The Science of Oil-Tanned Leather

To understand its performance, you must look at how oil-tanned leather is created and how that process directly impacts its interaction with water.

The Tanning Process: An Infused Barrier

Unlike a simple surface coating, the oils and waxes are not just applied to the top of the leather. During a process sometimes called "hot-stuffing," the hide is saturated with these compounds, allowing them to penetrate deep into its fibrous structure.

This infusion fills the microscopic voids within the leather that would otherwise absorb and hold moisture.

How It Repels Water

The infused oils create a hydrophobic surface. This works much like the natural oils on a duck's feathers, causing water to bead up due to surface tension.

Instead of being drawn into the material, the water droplets remain on the surface and are easily shed, keeping the interior of the boot dry under most conditions.

More Than Just Water Resistance

The oils serve a dual purpose. Beyond repelling water, they also continuously lubricate the leather's fibers. This keeps the material exceptionally supple, pliable, and resistant to drying out or cracking over time, contributing to the boot's overall longevity.

Understanding the Trade-offs

Oil-tanned leather is an exceptional material, but its effectiveness depends on understanding its limitations and maintenance requirements.

The Critical Distinction: Resistant vs. Waterproof

Water-resistant means the material can withstand water penetration to a significant degree, but not indefinitely. Oil-tanned leather excels at handling rain, snow, and walking through wet environments.

However, if submerged for a prolonged period, water will eventually saturate the leather. True waterproof boots typically rely on a separate internal membrane, like a Gore-Tex liner, to create an impermeable barrier.

The Essential Role of Maintenance

The protective oils are not permanent. Through scuffs, flexing, and exposure to dirt and detergents, these oils will gradually diminish.

Regularly cleaning your boots and reapplying a conditioning oil is not just for appearance; it is a critical step to replenish the leather's water resistance and keep it from drying out.

Construction Matters

The leather is only one part of a boot's defense against water. The way the boot is constructed is just as important. Features like a gusseted tongue (a tongue attached to the upper on both sides) and welted construction with minimal seams play a huge role in preventing water from entering through vulnerable areas.

Making the Right Choice for Your Goal

Select and maintain your footwear based on its intended use.

- If your primary focus is daily wear in moderate weather: Oil-tanned leather is an outstanding choice, offering a perfect balance of protection, breathability, and classic durability.

- If your primary focus is trekking through streams or constant, heavy rain: You should seek a boot that combines treated leather with a dedicated waterproof membrane for complete protection against saturation.

- If your primary focus is long-term durability: Commit to a simple maintenance schedule of cleaning and conditioning to ensure your oil-tanned boots perform for years to come.

By understanding how oil-tanned leather works, you can properly leverage its strengths and ensure your boots serve you well.

Summary Table:

| Feature | Key Takeaway |

|---|---|

| Primary Benefit | Creates a durable, hydrophobic barrier that causes water to bead up and roll off. |

| Key Distinction | Highly water-resistant, not fully waterproof. Protects against rain and snow. |

| Maintenance Need | Requires periodic cleaning and conditioning to replenish oils and maintain effectiveness. |

| Ideal Use Case | Perfect for daily wear and moderate weather conditions, offering breathability and durability. |

Need durable, high-performance work boots built with quality leathers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, including styles featuring oil-tanned and other specialized leathers for superior protection and longevity.

Contact our experts today to discuss your specific needs and discover how we can deliver the reliable footwear your customers demand.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Premium Oil Wax Leather Safety Boots for Bulk Purchase

People Also Ask

- How important is the fit of motorcycle boots? It's Critical for Safety and Control

- How does an industrial-grade piezoelectric ultrasonic transducer provide a non-injurious defense? Safe Canine Deterrence

- What are the insulation options in winter boots? Choose the Right Warmth for Your Winter Activity

- How does an 8-camera infrared motion capture system assist in evaluating footwear stability? Precision Biomechanics

- What are the advantages of an inverted mounting configuration for six-axis robots in footwear? Boost Precision & Reach

- How does Blake Stitch construction attach the shoe components? For Superior Flexibility & Sleek Design

- Why is the Leave-One-Subject-Out (LOSO) cross-validation strategy used in gait analysis? Ensuring Universal Accuracy

- How do operators personalize their gear in SEAL Team? Balancing Individuality with Mission Success