In short, insole and outsole production differ fundamentally in their objectives and materials. Insole manufacturing prioritizes internal comfort and fit, often skipping external branding processes like logo coloring and instead focusing on targeted material placement, such as using raw rubber in the forefront and specialized coloring on the heel before molding.

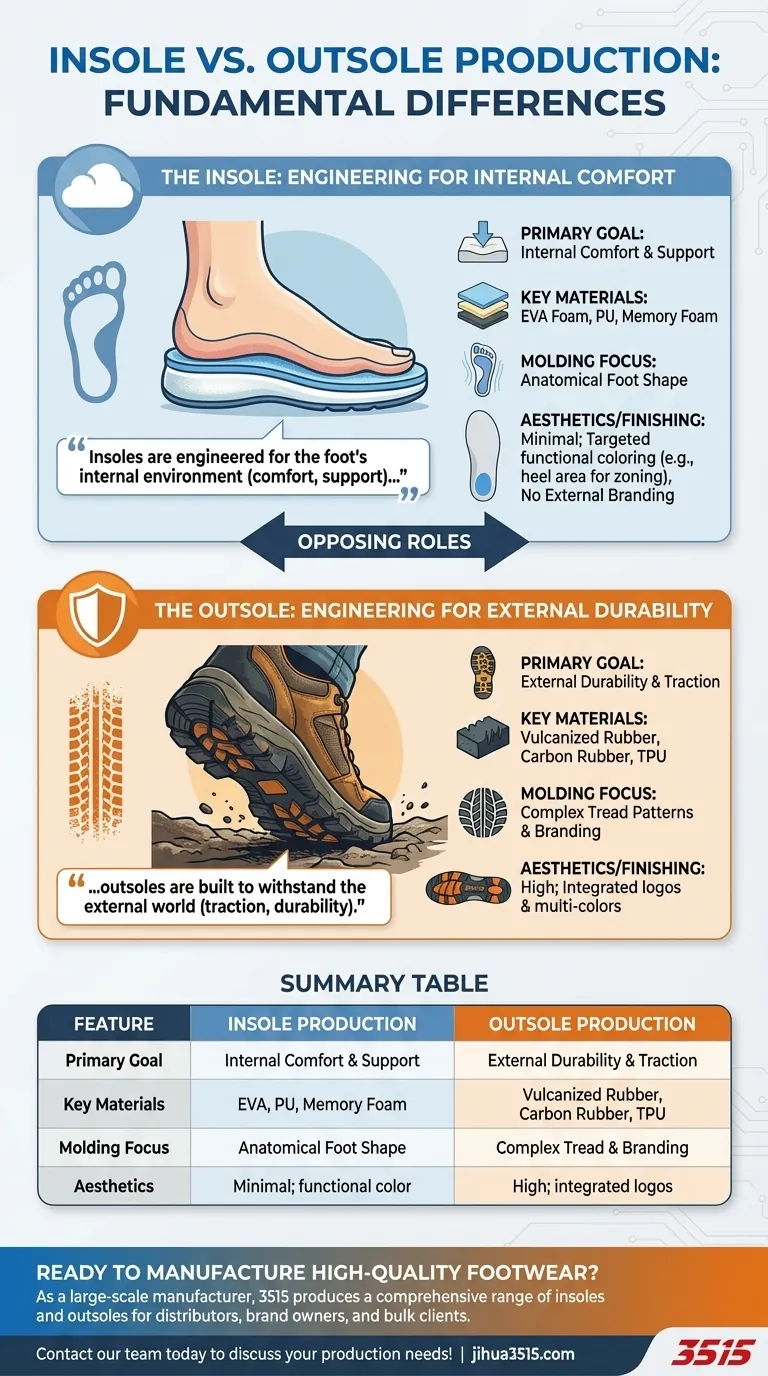

The core distinction stems from their opposing roles: insoles are engineered for the foot's internal environment (comfort, support), while outsoles are built to withstand the external world (traction, durability). This functional divide dictates every step, from material selection to the final molding process.

The Insole: Engineering for Internal Comfort

An insole, or footbed, is the layer directly beneath the foot. Its entire purpose is to provide cushioning, support, and a comfortable, stable platform inside the shoe.

Material Focus: Cushioning and Moisture Management

Insole materials are chosen for their shock absorption and flexibility. Common choices include EVA foam, polyurethane (PU), and memory foam.

As noted, specific areas might use different materials, like raw rubber for the forefront, to provide a distinct feel or response during the gait cycle.

Manufacturing Process: Anatomical Molding

The production process is centered on creating a precise anatomical shape.

Molds are heated to form the insole, but the finishing steps are minimal. Processes like logo and background coloring are typically skipped because they serve no functional purpose inside the shoe.

Instead, coloration is targeted, such as coloring the heel area to denote a specific zone of support or cushioning technology.

The Outsole: Engineering for External Durability

The outsole is the part of the shoe that makes direct contact with the ground. It must be tough, resilient, and provide reliable traction.

Material Focus: Abrasion Resistance and Grip

Outsole materials are dense and durable. Vulcanized rubber, carbon rubber, and Thermoplastic Polyurethane (TPU) are selected for their ability to resist wear and tear.

The composition is optimized for grip on various surfaces, a concern that is irrelevant for insoles.

Manufacturing Process: Complex Tread and Branding

Outsole production involves highly detailed molds that create complex tread patterns for traction.

Unlike insoles, this process almost always includes molding logos, brand names, and multi-colored sections directly into the rubber. This external-facing component is a key part of the shoe's aesthetic and branding.

Understanding the Key Production Divergences

The functional differences between insoles and outsoles create clear dividing lines in their manufacturing paths. Seeing them side-by-side makes the logic clear.

Material Selection and Purpose

The insole uses softer, lighter foams for cushioning. The outsole uses hard, dense rubbers for protection. This is the most fundamental divergence.

Molding Complexity and Detail

Insole molds focus on the gentle contours of the human foot.

Outsole molds are far more complex, incorporating deep lugs, intricate tread patterns, and high-fidelity branding elements that must withstand constant abrasion.

Finishing and Aesthetics

Insole finishing is purely functional, focusing on texture and shape. Any coloring is typically for zoning different densities of foam.

Outsole finishing is a critical aesthetic process. The integration of colors and logos is a primary consideration from the very beginning of the design phase.

Making the Right Choice for Your Goal

Understanding these production differences allows you to focus your resources where they matter most for your specific product.

- If your primary focus is user comfort and support: The insole's material composition and anatomical molding process will define the user's experience.

- If your primary focus is performance and longevity: The outsole's rubber compound, vulcanization process, and tread pattern are your most critical design variables.

- If your primary focus is visual branding: The outsole provides a durable and highly visible canvas for molded logos and strategic color blocking.

Ultimately, each component is manufactured with a singular, opposing purpose, and their production methods reflect that reality perfectly.

Summary Table:

| Feature | Insole Production | Outsole Production |

|---|---|---|

| Primary Goal | Internal Comfort & Support | External Durability & Traction |

| Key Materials | EVA Foam, PU, Memory Foam | Vulcanized Rubber, Carbon Rubber, TPU |

| Molding Focus | Anatomical Foot Shape | Complex Tread Patterns & Branding |

| Aesthetics/Finishing | Minimal; targeted functional coloring | High; integrated logos & multi-colors |

Ready to manufacture high-quality footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of insoles and outsoles for distributors, brand owners, and bulk clients. Our expertise ensures your footwear delivers on both comfort and durability.

Contact our team today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- How is the long-term effectiveness of slip-resistant outsoles evaluated? Real-World Monitoring for Safety Excellence

- Why is a constant temperature drying oven necessary? Ensure Quality in Nano-Modified Rubber Production

- How high-pressure vulcanizing machines ensure anti-slip outsole performance? Key to superior grip and durability.

- What are the main components created during the shoe sole manufacturing process? Insole, Midsole, and Outsole Explained

- Why is the sourcing process for natural rubber considered sustainable? Discover the Renewable Harvest

- Why might someone prefer leather soles over rubber soles? Discover the Elegance and Comfort

- How does natural rubber contribute to shock absorption in footwear? Unlock Superior Comfort & Durability

- What are the main differences between leather and rubber shoe soles? Choose the Right Sole for Your Needs