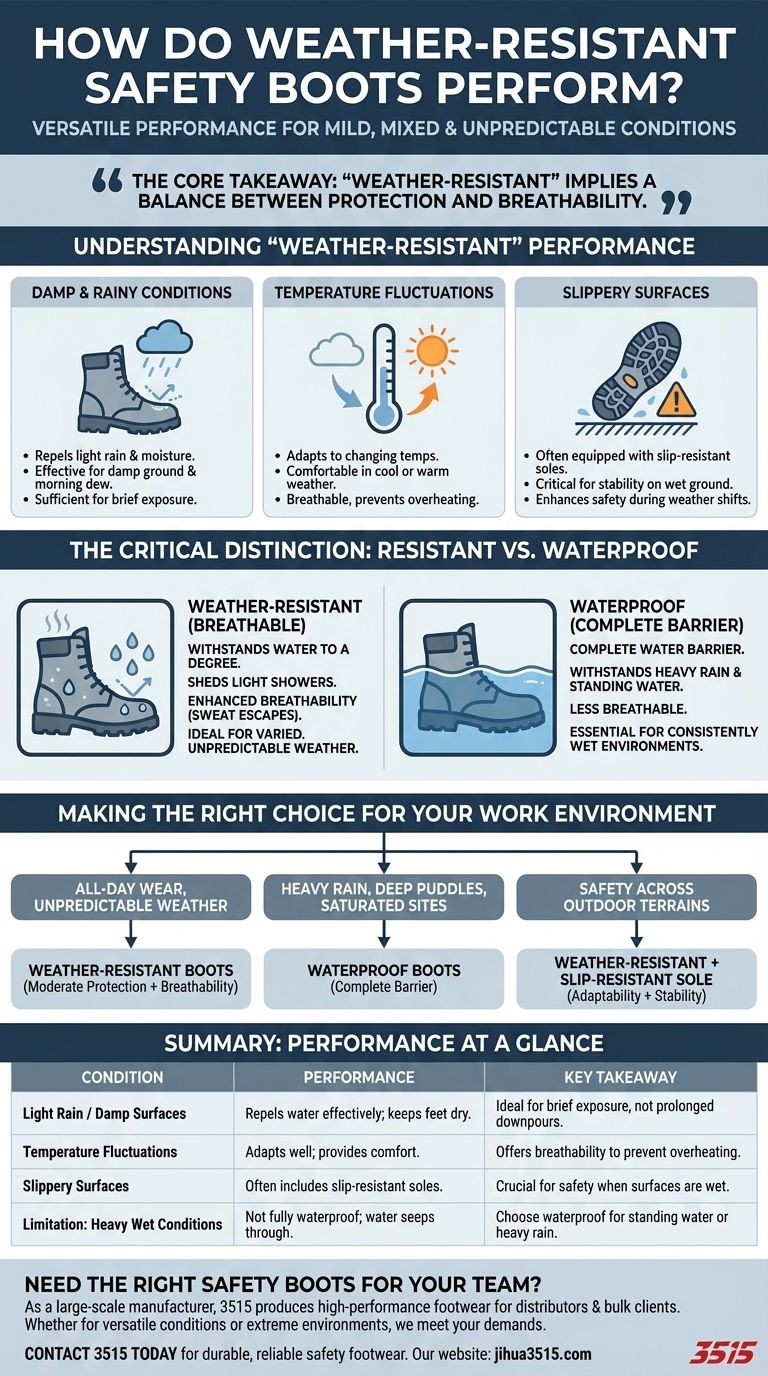

To put it simply, weather-resistant safety boots are highly versatile performers for mild, mixed, and unpredictable conditions. They are designed to keep your feet dry from light rain and comfortable during temperature shifts from a cool morning to a hot afternoon. However, their protection has clear limits, and they are not a substitute for fully waterproof boots in consistently wet or extreme environments.

The core takeaway is that "weather-resistant" implies a balance between protection and breathability. It excels in fending off moderate weather challenges but will not provide the complete barrier against water that a "waterproof" boot offers.

What "Weather-Resistant" Really Means

Understanding the specific performance characteristics of these boots allows you to match them to your actual working conditions, ensuring both safety and comfort.

Performance in Damp and Rainy Conditions

Weather-resistant boots typically use specially treated leather or materials that repel water. This makes them very effective at keeping your feet dry during light rain showers, walking on damp ground, or through morning dew.

This resistance is sufficient for brief exposure to moisture.

Performance in Temperature Fluctuations

A key advantage is their adaptability to changing temperatures. The materials used are generally not thermal conductors, meaning they don't readily transfer heat or cold.

This allows them to feel comfortable on a cool, damp morning and remain breathable during a hot, humid afternoon, preventing your feet from overheating. Some also include moisture-wicking properties to manage sweat.

Performance on Slippery Surfaces

Many boots in this category, such as Packer-style boots, incorporate safety features beyond just weather resistance.

It is common for them to be equipped with slip-resistant soles. This is a critical feature for maintaining stable footing when a sudden change in weather makes surfaces wet and hazardous.

The Critical Distinction: Resistant vs. Waterproof

The most common point of failure is misunderstanding the difference between "resistant" and "waterproof." This distinction is the single most important factor in your decision.

The Limit of "Resistant"

Water-resistant means the material can withstand water penetration to a certain degree. It will shed a light shower, but under prolonged exposure or heavy pressure—like a downpour or stepping in a deep puddle—water will eventually seep through.

The Benefit of Breathability

The trade-off for not being a perfect seal against water is enhanced breathability. Weather-resistant boots allow moisture vapor (sweat) to escape more easily than fully waterproof models.

This is a significant advantage for comfort during long workdays, especially in warmer conditions, as it helps keep your feet dry from the inside.

When to Choose Waterproof Instead

You absolutely need waterproof boots if your work regularly involves standing water, heavy and consistent rain, or trekking through deep mud and slush.

Waterproof boots create a complete barrier. While often less breathable, they are the only reliable option for keeping your feet dry in extremely wet conditions.

Making the Right Choice for Your Work Environment

Selecting the correct boot is about honestly assessing your daily conditions.

- If your primary focus is all-day wear in varied, unpredictable weather: Weather-resistant boots offer the ideal blend of moderate protection and crucial breathability.

- If your primary focus is working in heavy rain, deep puddles, or saturated sites: You must choose a boot that is explicitly rated as waterproof.

- If your primary focus is safety across different outdoor terrains: A weather-resistant boot with a certified slip-resistant sole provides excellent adaptability for changing ground conditions.

Ultimately, choosing the right boot means matching its specific capabilities to the reality of your workday.

Summary Table:

| Condition | Performance of Weather-Resistant Boots | Key Takeaway |

|---|---|---|

| Light Rain / Damp Surfaces | Repels water effectively; keeps feet dry. | Ideal for brief exposure, not prolonged downpours. |

| Temperature Fluctuations | Adapts well; provides comfort in both cool and warm weather. | Offers breathability to prevent overheating. |

| Slippery Surfaces | Often includes slip-resistant soles for stability. | Crucial for safety when weather makes surfaces wet. |

| Limitation: Heavy Wet Conditions | Not fully waterproof; water will seep through under pressure. | Choose waterproof boots for standing water or heavy rain. |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Whether your workforce needs versatile weather-resistant boots for unpredictable conditions or fully waterproof models for extreme environments, we have the production capabilities and expertise to meet your demands.

Contact 3515 today to discuss your specific requirements and get a quote for durable, reliable safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How does professional industrial cleaning equipment maintain the performance stability of safety shoes? Pro Maintenance

- What technical advantages are gained by integrating embedded controllers into footwear? Boost Safety with Smart Tech

- What are the production benefits of choosing modular electronic components for smart protective footwear? Scale Faster

- Can composite toe shoes be used after an accident? No, Here's the Critical Safety Rule

- What organization develops safety standards for protective footwear in the U.S.? A Guide to ASTM and OSHA Compliance

- What are the primary functions of industrial-grade safety shoes? Protect Workers in Grinding & Cutting Operations

- In what way do assistive devices like crutches and protective footwear synergize during early-stage load management?

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team