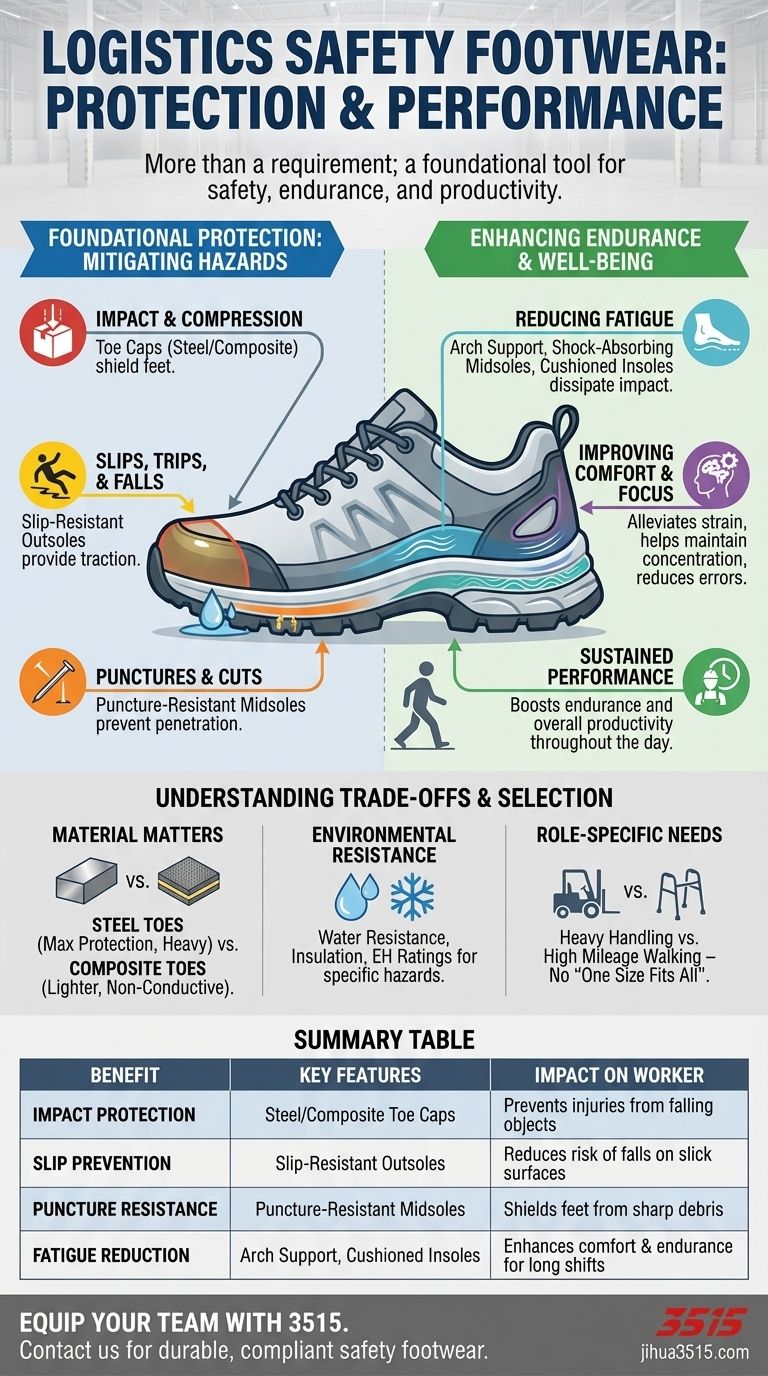

For a logistics worker, safety shoes are far more than a requirement; they are a foundational tool for both protection and performance. They directly mitigate the daily risks of falling objects and slippery floors through features like protective toe caps and high-traction outsoles, while also reducing the cumulative physical strain of long shifts on hard surfaces.

Beyond preventing obvious injuries from impacts and slips, the right safety footwear acts as a system to reduce fatigue. This enhances a worker's endurance, focus, and overall productivity throughout their day.

Foundational Protection: Mitigating Immediate Hazards

The most apparent benefit of safety shoes is their ability to prevent acute injuries. The logistics environment is filled with immediate physical risks that properly specified footwear is designed to counter.

Guarding Against Impact and Compression

The primary danger in handling goods is from falling objects or rolling equipment. Protective toe caps, made from materials like steel, alloy, or composites, are engineered to shield the feet from severe impact and compression forces.

This protection is critical around loading docks, pallet jacks, and shelving units where heavy items can easily be dropped or dislodged.

Preventing Slips, Trips, and Falls

Warehouse floors are notoriously hazardous due to spills, dust, and polished concrete surfaces. Safety shoes with slip-resistant outsoles provide essential traction, significantly reducing the risk of falls.

The specific tread pattern and rubber compound of the sole are designed to channel away liquids and grip surfaces, ensuring stable footing during rapid movement.

Shielding from Punctures and Cuts

The floor of a busy logistics center can be littered with unseen dangers like nails, screws, and sharp metal or wood fragments.

Many safety shoes incorporate puncture-resistant midsoles, a flexible plate that prevents sharp objects from penetrating the bottom of the shoe and injuring the foot.

Enhancing Worker Endurance and Well-being

An often-overlooked function of safety footwear is its role in promoting long-term health and reducing fatigue. This is not a luxury but a critical component of sustained performance.

Reducing Physical Fatigue

Logistics professionals spend the majority of their shifts standing and walking on unforgiving concrete floors. This places immense strain on the feet, legs, and lower back.

Modern safety shoes integrate ergonomic features like arch support, shock-absorbing midsoles, and cushioned insoles. These elements work together to dissipate impact forces and reduce muscle fatigue, allowing workers to stay comfortable and effective for longer.

Improving Comfort and Focus

Persistent discomfort is a major distraction that can lead to a loss of focus and an increased likelihood of human error.

By alleviating physical strain, well-designed safety footwear helps workers maintain concentration on their tasks. This directly contributes to a safer and more productive operation.

Understanding the Trade-offs and Selection Criteria

Not all safety shoes are created equal. Choosing the right shoe requires a clear understanding of the specific work environment and the trade-offs between different materials and features.

Material Matters: Steel vs. Composite Toes

The material of the protective toe cap is a key decision. Steel toes offer maximum protection but are heavier and conduct heat and cold.

Composite toes are lighter, do not conduct temperature or electricity, and are ideal for metal-free environments. However, they can sometimes be bulkier to achieve the same impact rating as steel.

Assessing Environmental Resistance

The specific hazards of the environment dictate the necessary features. Consider requirements for water resistance in wet areas, insulation for cold storage, or electrical hazard (EH) ratings for areas with potential live circuits.

The Myth of "One Size Fits All"

A shoe that is perfect for a forklift operator may be unsuitable for a picker who walks several miles per day. The selection process must account for the unique demands of each role within the logistics chain.

Selecting the Right Footwear for the Task

To make an informed decision, align the footwear's features with the primary demands of the job.

- If your primary focus is heavy material handling: Prioritize shoes with the highest impact rating (steel or alloy toe caps) and consider adding metatarsal guards for top-of-foot protection.

- If your primary focus is navigating varied floor surfaces: Emphasize slip-resistant outsoles with a tread pattern designed for both wet and dry conditions.

- If your primary focus is worker endurance over long shifts: Look for features like anti-fatigue midsoles, cushioned insoles, and lightweight composite materials to minimize strain.

- If your primary focus is a specialized environment (e.g., cold storage): Ensure the footwear includes thermal insulation and water resistance to maintain safety and comfort.

Investing in the correct safety footwear is a direct investment in the health, safety, and productivity of your most valuable asset: your people.

Summary Table:

| Benefit | Key Features | Impact on Worker |

|---|---|---|

| Impact Protection | Steel/Composite Toe Caps | Prevents injuries from falling objects |

| Slip Prevention | Slip-Resistant Outsoles | Reduces risk of falls on slick surfaces |

| Puncture Resistance | Puncture-Resistant Midsoles | Shields feet from sharp debris |

| Fatigue Reduction | Arch Support, Cushioned Insoles | Enhances comfort and endurance for long shifts |

Equip your logistics team with footwear that protects and performs. As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of occupational footwear designed to meet the specific demands of warehouse and logistics work. We can help you source durable, comfortable, and compliant safety footwear to safeguard your workforce and boost productivity. Contact us today for a consultation and discover the 3515 advantage.

Visual Guide

Related Products

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What are aramid threads and why are they used in firefighter boots? Essential for Uncompromising Safety

- What are the primary protective functions of industrial safety shoes in pharmaceutical QC labs? Ensure Lab Safety

- Which organizations create and enforce safety footwear regulations? Understand ASTM and OSHA Roles

- What are the primary protective functions of professional safety shoes within the Ready-Made Garment (RMG) manufacturing industry? Ensure Worker Safety & Well-being

- Why is it mandatory for personnel to wear anti-slip industrial safety shoes during salt loading? Prevent Slip Hazards

- What are the common types of upper materials for labour protection shoes? Choose the Right Material for Your Work Environment

- What are the key ASTM standards for protective footwear compliance? Ensure Workplace Safety & OSHA Compliance

- How can understanding the materials used in safety shoes help in choosing the right product? A Guide to Matching Footwear to Hazards