At their core, safety boots reduce cutting hazards by using a system of highly durable and puncture-resistant materials in their construction. Key features like reinforced uppers, protective toe caps, and specialized midsoles create a formidable barrier that can stop or deflect sharp objects, from powered tools like chainsaws to environmental debris like nails and scrap metal.

The real insight is that cut protection in safety footwear isn't about a single feature. It's an integrated system where the boot's entire structure—from the sole to the upper—is engineered to shield the foot from the specific cutting threats present in a hazardous work environment.

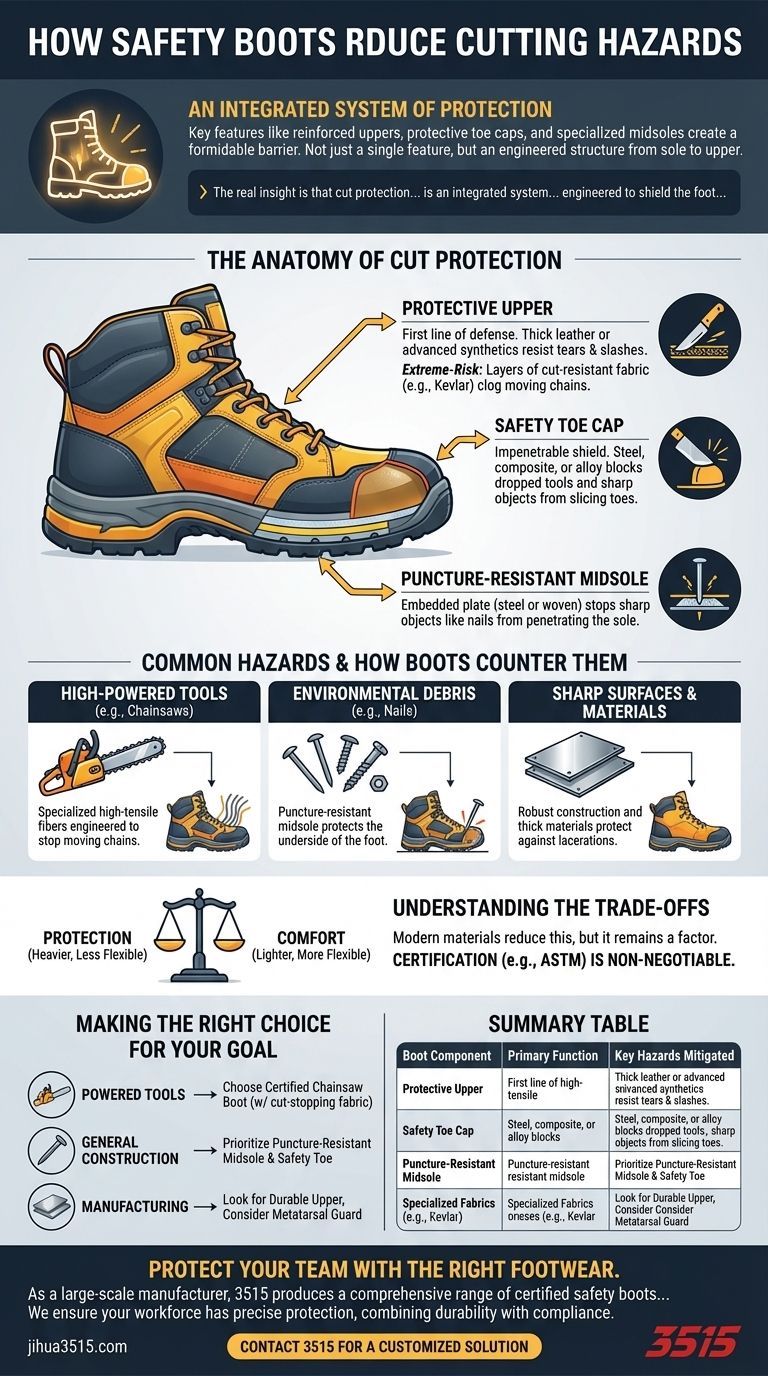

The Anatomy of Cut Protection

To understand how safety boots work, you must look at them as a collection of specialized components, each playing a critical role in preventing injury.

The Protective Upper

The main body of the boot, known as the "upper," provides the first line of defense. It is typically made from thick, durable leather or advanced synthetic materials designed to resist tears and slashes from incidental contact with sharp edges.

For extreme-risk jobs, such as logging, boots often incorporate layers of specialized cut-resistant fabric like Kevlar. These materials are designed to shred and clog the chain of a moving chainsaw, stopping it before it can cause serious injury.

The Safety Toe Cap

While famous for protecting against crushing and impact, the safety toe (made of steel, composite, or alloy) also serves as an impenetrable shield against cutting hazards. It effectively blocks dropped tools, blades, or other sharp, heavy objects from slicing into the toes.

The Puncture-Resistant Midsole

One of the most common workplace dangers is stepping on a sharp object. To counter this, many safety boots feature a puncture-resistant plate embedded in the midsole. This can be a steel plate or a more flexible woven fabric, designed specifically to stop nails, screws, and other sharp debris from cutting through the sole of the foot.

Common Hazards and How Boots Counter Them

Different work environments present unique cutting threats. A boot's effectiveness depends on its design being matched to the specific hazard.

High-Powered Cutting Tools

Tools like chainsaws and rotary mowers pose an extreme cutting risk. Standard work boots offer minimal protection here. Certified chainsaw boots are required, as they contain the specialized high-tensile fibers mentioned earlier that are engineered to stop a moving chain on contact.

Environmental Debris

Construction sites and demolition zones are often littered with nails, old screws, staples, and sharp scrap metal. The puncture-resistant midsole is the critical feature for protecting the underside of the foot from these pervasive and dangerous hazards.

Sharp Surfaces and Materials

Working with materials like sheet metal or navigating rough, sharp terrain requires overall boot durability. The robust construction and thick materials of the entire boot protect against lacerations and cuts that can occur from everyday movements and contact on the job site.

Understanding the Trade-offs

It's crucial to recognize that there is no single boot for every hazard. The design choices that excel in one area may be a compromise in another.

Protection vs. Flexibility

Highly protective boots, especially those with steel plates and multiple layers of cut-resistant fabric, are often heavier and less flexible. This can lead to fatigue over a long workday. Modern composite materials aim to reduce this trade-off, but it remains a factor.

Specialized vs. General Use

A boot designed for a logger has extreme cut resistance but may be overkill and unnecessarily cumbersome for an electrician or warehouse worker. Choosing a boot with features you don't need can add unnecessary cost and weight.

Certification is Non-Negotiable

Never assume a boot is protective just because it looks tough. Always look for official safety ratings (like ASTM standards) that certify the boot's specific protective capabilities, including puncture resistance and toe protection.

Making the Right Choice for Your Goal

Selecting the correct safety boot requires a clear understanding of your primary risks.

- If your primary focus is protection from powered tools like chainsaws: You must choose a boot specifically certified for that task, which will contain specialized cut-stopping fabric layers.

- If your primary focus is general construction or demolition hazards: Prioritize a boot with a certified safety toe and, most importantly, a puncture-resistant midsole.

- If your primary focus is manufacturing with sharp materials: Look for a durable upper and consider an added metatarsal guard for complete top-of-foot protection.

Ultimately, choosing the right safety boot is a critical, proactive investment in your personal well-being on the job.

Summary Table:

| Boot Component | Primary Function | Key Hazards Mitigated |

|---|---|---|

| Protective Upper | First line of defense; resists tears and slashes | Sharp edges, incidental contact |

| Safety Toe Cap | Shields toes from impact and cutting | Dropped tools, blades, heavy sharp objects |

| Puncture-Resistant Midsole | Stops sharp objects from penetrating the sole | Nails, screws, staples, scrap metal |

| Specialized Fabrics (e.g., Kevlar) | Stops moving chains by clogging the mechanism | Chainsaws, high-powered cutting tools |

Protect your team with the right footwear for the job.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, from general-purpose boots with puncture-resistant soles to specialized chainsaw-resistant models.

We ensure your workforce has the precise protection they need, combining durability with safety standards compliance.

Contact 3515 today to discuss your specific safety footwear requirements and receive a customized solution.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What is a working boot? Your Essential Guide to Foot Safety and Durability

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What distinguishes heavy duty work boots from regular boots? Safety, Durability & Purpose Explained

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- What should I look for in a safety shoe? Find the Perfect Protection for Your Job