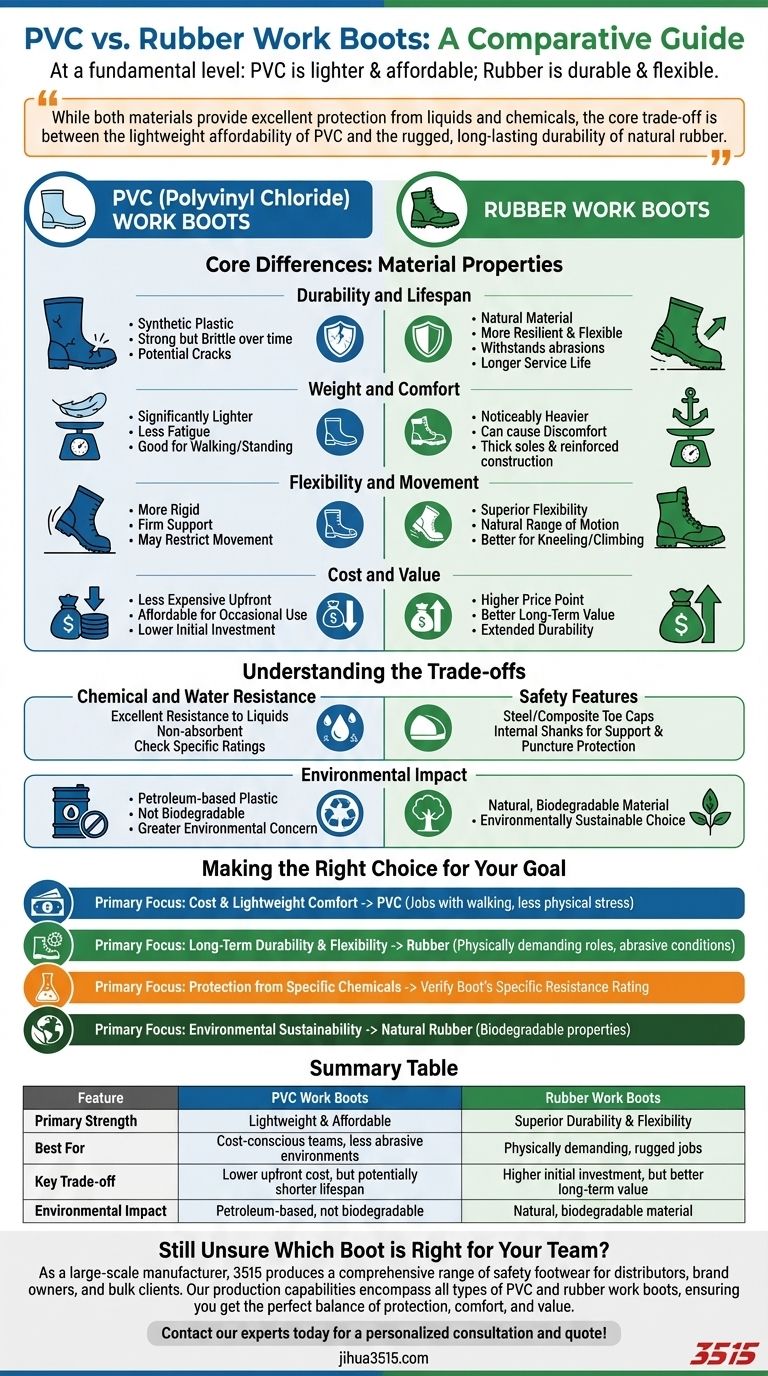

At a fundamental level, PVC work boots are a lighter, more affordable, and completely waterproof option, whereas rubber boots offer superior durability, flexibility, and environmental friendliness. The choice between them depends entirely on your specific work environment and priorities.

While both materials provide excellent protection from liquids and chemicals, the core trade-off is between the lightweight affordability of PVC and the rugged, long-lasting durability of natural rubber.

The Core Differences: Material Properties

The characteristics of each material directly impact the boot's performance, comfort, and longevity on the job.

Durability and Lifespan

PVC (Polyvinyl Chloride) is a synthetic plastic. While strong, it can become brittle over time, especially with exposure to extreme temperatures or chemicals, potentially leading to cracks.

Rubber, being a natural material, is inherently more resilient and flexible. It withstands abrasions, punctures, and daily wear-and-tear more effectively, generally resulting in a longer service life.

Weight and Comfort

PVC boots are significantly lighter than their rubber counterparts. This reduced weight can lead to less fatigue during long shifts that involve extensive walking or standing.

Rubber boots are noticeably heavier, particularly those with thick soles and reinforced construction. This added weight can cause discomfort and strain over a full workday.

Flexibility and Movement

Rubber offers superior flexibility, allowing for a more natural range of motion when walking, kneeling, or climbing. This is a critical factor for comfort in physically demanding jobs.

PVC is a more rigid material. While this provides firm support, it can restrict movement and feel less comfortable compared to the pliancy of rubber.

Cost and Value

PVC boots are generally less expensive to manufacture, making them the more affordable option upfront. This makes them a popular choice for occasional use or for large teams needing basic protection.

Rubber boots, due to the cost of the raw material and manufacturing process, come at a higher price point. However, their extended durability can offer better long-term value.

Understanding the Trade-offs

Choosing the right boot requires balancing protection, comfort, and cost. There is no single "best" material; there is only the best material for your specific application.

Chemical and Water Resistance

Both PVC and rubber boots are primarily used for their excellent resistance to liquids, making them ideal for Haz-Mat, chemical handling, and wet environments.

They are non-absorbent and can be certified as chemical-resistant to prevent the penetration of harmful substances. Always check the boot's specific ratings against the chemicals you handle.

Safety Features

Modern work boots made from either material can be equipped with critical safety components. This includes steel or composite toe caps for impact protection.

They can also feature internal shanks (steel, composite, or nylon) to provide arch support and protection from punctures from below.

Environmental Impact

This is a clear differentiator. Rubber is a natural, biodegradable material, making it a more environmentally sustainable choice.

PVC is a petroleum-based plastic that is not biodegradable, posing a greater environmental concern at the end of its life cycle.

Making the Right Choice for Your Goal

Your daily tasks and work environment should be the ultimate guide in your decision.

- If your primary focus is cost and lightweight comfort: PVC is the superior choice for jobs with lots of walking where boots may not be subjected to extreme physical stress.

- If your primary focus is long-term durability and flexibility: Rubber is the better investment for physically demanding roles that require frequent kneeling and exposure to abrasive conditions.

- If your primary focus is protection from specific chemicals: You must verify the boot's specific resistance rating, as performance can vary between different formulations of both PVC and rubber.

- If your primary focus is environmental sustainability: Natural rubber is the clear winner due to its biodegradable properties.

Ultimately, understanding the inherent properties of each material empowers you to select the boot that best serves your safety and comfort.

Summary Table:

| Feature | PVC Work Boots | Rubber Work Boots |

|---|---|---|

| Primary Strength | Lightweight & Affordable | Superior Durability & Flexibility |

| Best For | Cost-conscious teams, less abrasive environments | Physically demanding, rugged jobs |

| Key Trade-off | Lower upfront cost, but potentially shorter lifespan | Higher initial investment, but better long-term value |

| Environmental Impact | Petroleum-based, not biodegradable | Natural, biodegradable material |

Still Unsure Which Boot is Right for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of PVC and rubber work boots, ensuring you get the perfect balance of protection, comfort, and value.

Let us help you make the right choice. We can guide you to the optimal boot for your specific work environment and requirements.

Contact our experts today for a personalized consultation and quote!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What is the purpose of insulation in work boots? Essential for Warmth and Safety in Cold Conditions

- How should wildland firefighter boots be broken in? A Phased Guide for Safety & Performance

- What should be kept in mind when trying on boots? A Guide to the Perfect Fit

- Can motorcycle boots be worn for everyday use? Finding the Perfect Balance for Daily Wear

- Why is it important to choose work boots based on occupation? Match Your Boots to Your Job's Hazards

- What makes Western-style work boots comfortable? Unlock All-Day Comfort with Advanced Design

- What are toe caps in work boots and why are they important? Choose the Right Protection for Your Job

- Why is choosing the right work boot important? The Ultimate Guide to Industry-Specific Footwear Safety