At their core, non-slip shoes work by using a combination of specialized materials and intelligent design to maximize friction between the outsole and the ground. They achieve this through softer, high-grade rubber compounds for better grip, and intricate tread patterns with deep grooves that are engineered to channel liquids like water and oil away from the point of contact.

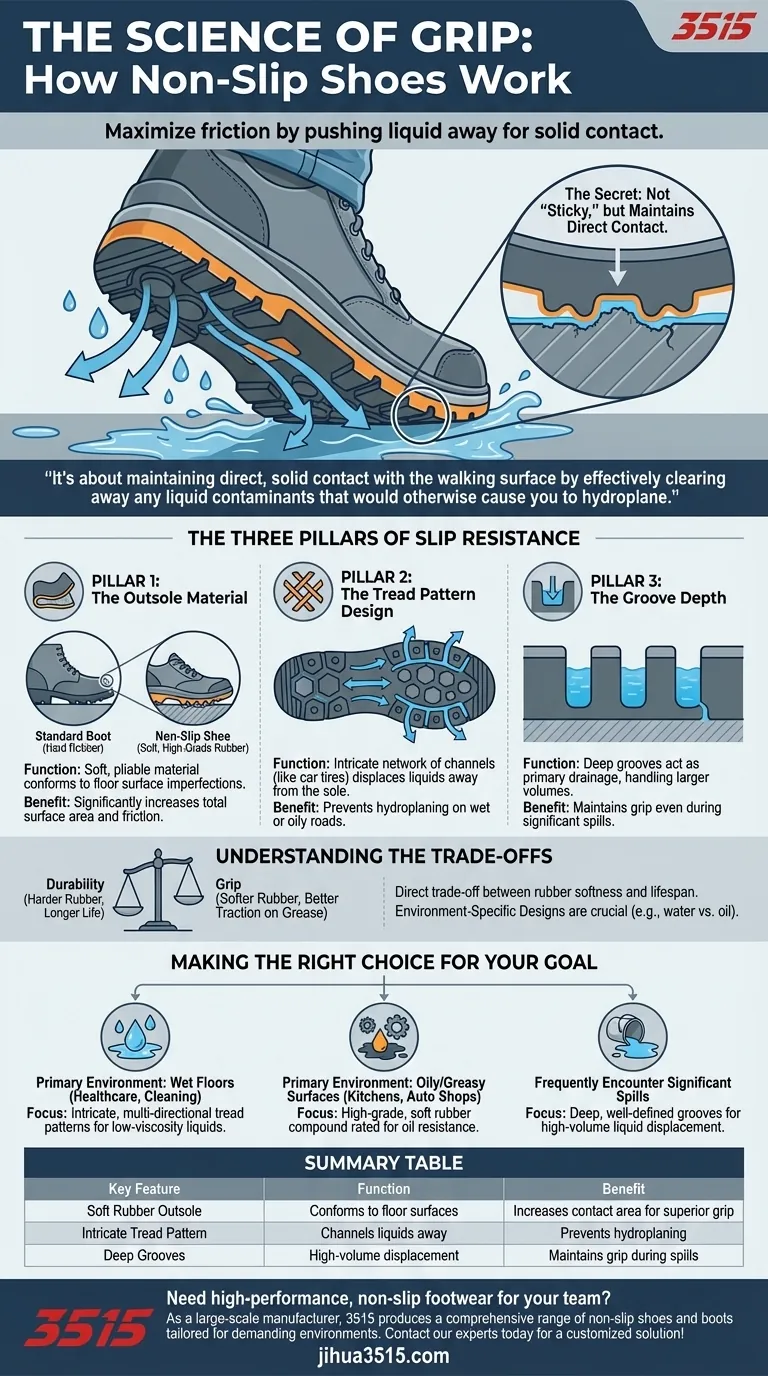

The secret to a non-slip shoe isn't about being "sticky." It's about maintaining direct, solid contact with the walking surface by effectively clearing away any liquid contaminants that would otherwise cause you to hydroplane.

The Science of Grip: Maximizing Friction

To understand how non-slip shoes work, we first have to understand the enemy: a thin layer of liquid. When water, oil, or grease gets between your shoe and the floor, it dramatically reduces the coefficient of friction, creating a dangerous slipping hazard.

It's All About Contact

The entire goal of a slip-resistant shoe is to prevent that layer of liquid from forming. It does this by creating a system that allows the liquid to be pushed out from under the sole, ensuring the rubber makes as much direct contact with the floor as possible.

The Three Pillars of Slip Resistance

Three key design features work in unison to achieve this goal. A truly effective non-slip shoe excels in all three areas, not just one.

Pillar 1: The Outsole Material

The foundation of grip is the material itself. Non-slip shoes use high-grade, often softer rubber compounds.

Unlike the hard, durable rubber on a standard boot, this softer material is more pliable. It can conform to the microscopic imperfections of a floor surface, significantly increasing the total surface area of contact and, therefore, the available friction.

Pillar 2: The Tread Pattern Design

The specific shape of the treads is arguably the most critical element. You will often see small, repeating patterns like circles or hexagons.

These aren't for aesthetics. They create a network of fine channels that allow liquids to be displaced away from the center of the sole. Think of it like the treads on a car tire, which are designed to prevent hydroplaning on a wet road by pushing water out to the sides.

Pillar 3: The Groove Depth

The main grooves between the tread blocks serve as the primary drainage system. The deeper these grooves are, the more liquid they can handle.

Deeper grooves provide a higher capacity for channeling away larger volumes of fluid. This ensures that even in the event of a significant spill, the sole can maintain its grip on the actual floor surface rather than floating on top of the liquid.

Understanding the Trade-offs

No single shoe design is perfect for every condition. Understanding the inherent compromises is key to choosing the right tool for the job.

Durability vs. Grip

There is often a direct trade-off between the softness of the rubber and its lifespan. An extremely soft compound that offers phenomenal grip on greasy kitchen tiles may wear down much faster than a harder rubber.

Environment-Specific Designs

The ideal tread pattern for displacing water may not be the most effective for more viscous liquids like oil. This is why you see specialized shoes for different industries, each with a slightly different outsole design optimized for the contaminants most common in that environment.

Making the Right Choice for Your Goal

By understanding these principles, you can look beyond marketing terms and evaluate a shoe based on its functional design.

- If your primary environment involves wet floors (e.g., healthcare, cleaning): Focus on shoes with intricate, multi-directional tread patterns designed to channel away low-viscosity liquids quickly.

- If your primary environment involves oily or greasy surfaces (e.g., kitchens, auto shops): Prioritize a shoe made with a high-grade, soft rubber compound specifically rated for oil resistance.

- If you frequently encounter significant spills: Ensure the shoe has deep, well-defined grooves to provide the capacity needed to handle larger volumes of liquid without losing contact.

Ultimately, choosing the right shoe is about matching its design features to the specific hazards you face every day.

Summary Table:

| Key Feature | Function | Benefit |

|---|---|---|

| Soft Rubber Outsole | Conforms to floor surfaces | Increases contact area for superior grip |

| Intricate Tread Pattern | Channels liquids away from sole | Prevents hydroplaning on wet/oily floors |

| Deep Grooves | Provides high-volume liquid displacement | Maintains grip even during significant spills |

Need high-performance, non-slip footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of non-slip shoes and boots tailored for demanding environments like kitchens, healthcare, and industrial settings. Our expertise in material science and tread design ensures your distributors, brand owners, and bulk clients receive footwear that combines superior slip resistance with lasting durability.

Let's discuss your specific needs and volume requirements. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What is the significance of tread patterns in non-slip shoes? Prevent Slips with Expert Sole Design

- What makes slip-resistant shoes essential for food service or industrial jobs? Prevent Costly Slips & Falls

- How does the floor type affect slip-resistant shoe choice? Match Your Sole to Your Surface

- Why is proper footwear important for people who stand all day? Prevent Pain & Boost Productivity

- What are the common types of non-slip shoes available? Find the Right Traction for Your Work Environment

- Is there a difference between non-slip and slip-resistant shoes? Focus on the Features That Matter.

- What is the significance of slip resistance in work shoes? Essential Safety for High-Risk Environments

- What are alternatives to rubber for slip-resistant soles? Discover the Best Material for Your Environment