Goodyear welt construction evolved from a time-consuming, hand-sewn technique into a mechanized process that revolutionized the footwear industry. Patented by Charles Goodyear Jr. in the latter half of the 19th century, his machinery made this durable and water-resistant construction method scalable, establishing it as the global standard for quality footwear for nearly a century.

The history of the Goodyear welt is not just about a machine; it's about how a brilliant innovation made superior durability and repairability accessible, cementing a method of construction that remains the gold standard for high-quality footwear today.

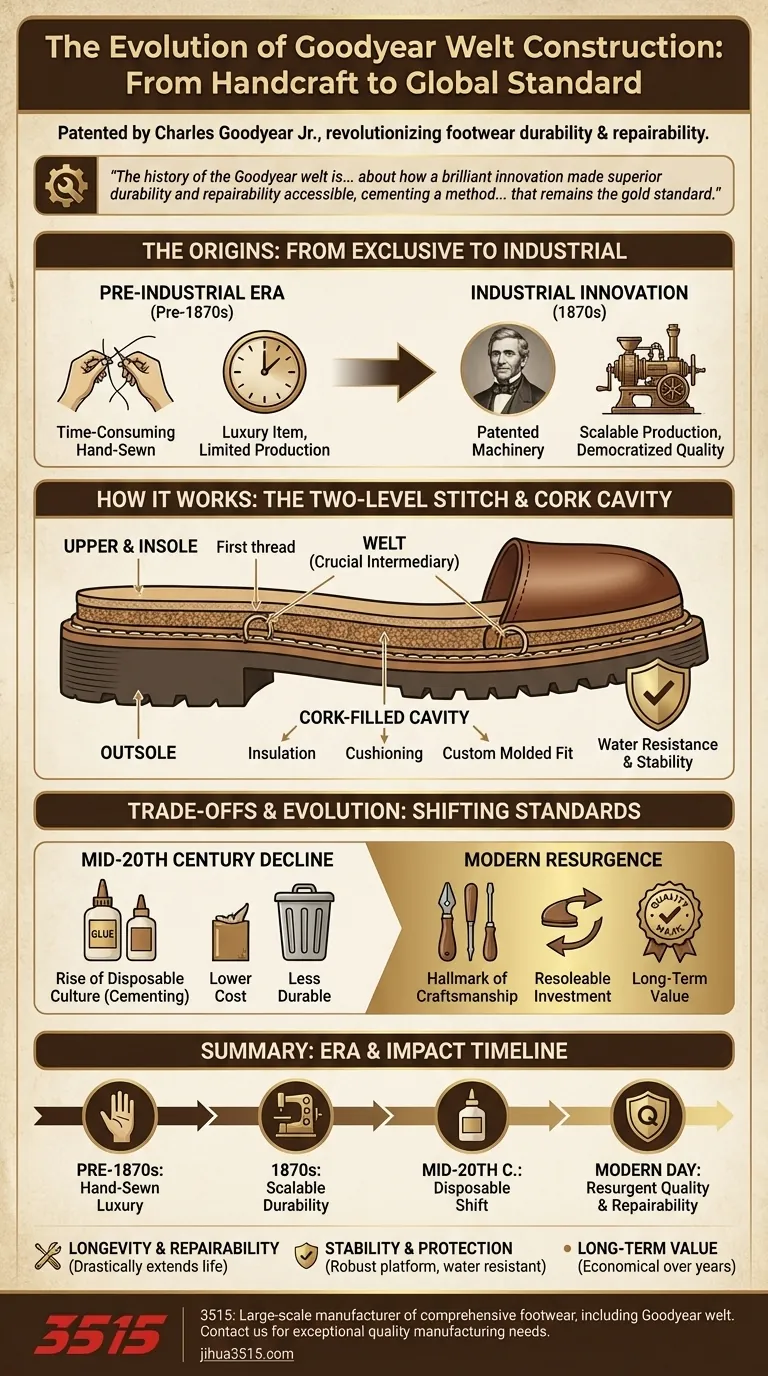

The Origins: From Exclusive Handcraft to Industrial Standard

The story of the Goodyear welt is a classic example of industrial innovation democratizing quality. What was once reserved for the wealthy became the benchmark for well-made, accessible shoes.

The Pre-Industrial Era

Before the mid-1800s, attaching a shoe's sole with a welt was done entirely by hand. This painstaking process was slow and required immense skill, making welted footwear a luxury item with very limited production capacity.

The Innovation of Charles Goodyear Jr.

The turning point came when Charles Goodyear Jr. developed and patented a series of stitching machines around the 1870s. These machines could replicate the complex welting process with speed and precision, fundamentally changing footwear manufacturing forever.

The Impact of Mechanization

This new technology allowed factories to produce durable, water-resistant, and resoleable boots at a scale never before seen. The Goodyear welt method quickly became the dominant construction standard for quality shoes and boots, a position it held firmly into the mid-20th century.

How the Construction Method Actually Works

The genius of the Goodyear welt lies in its indirect attachment method, which creates a uniquely robust and repairable product. It’s fundamentally a two-level stitching process.

The Role of the Welt

The welt is a strip of leather that runs along the perimeter of the outsole. It acts as the crucial intermediary, connecting the upper part of the shoe to the sole without stitching directly through the insole from the outside.

A Two-Level Stitching Process

First, the machine stitches the shoe's upper and insole to the welt. Second, in a separate step, the outsole is stitched directly to the welt. This dual-stitch system creates an exceptionally strong bond.

The Cork-Filled Cavity

This construction method creates a cavity between the insole and the outsole. This space is filled with a layer of cork, which provides excellent insulation, cushioning, and gradually molds to the shape of your foot for a custom fit over time.

Understanding the Trade-offs and Evolution

While revered, the Goodyear welt saw its dominance challenged by cheaper, faster methods. Its modern status as a premium feature is a direct result of these historical shifts.

The Shift to Disposable Culture

In the mid-20th century, the rise of less expensive construction methods, like cementing (gluing) soles, led to a decline in Goodyear welting. The market shifted toward cheaper, more disposable footwear, prioritizing low cost over longevity.

Durability and True Resoleability

The primary benefit of the Goodyear welt is its resoleability. Because the outsole is stitched to the welt and not the upper, a cobbler can easily remove and replace a worn-out sole multiple times without compromising the shoe's structure.

Water Resistance and Stability

The welt acts as a buffer or an extra layer, preventing water from easily seeping into the shoe from the edge where the sole meets the upper. This creates a far more water-resistant and stable shoe compared to simpler constructions.

The Modern Mark of Quality

Today, Goodyear welt construction has had a resurgence. It is now widely recognized as a hallmark of superior craftsmanship, durability, and value, chosen by consumers who prioritize products that are built to last and can be repaired rather than replaced. The initial higher cost and break-in period are seen as an investment in long-term performance.

Making the Right Choice for Your Goal

Understanding this history helps you recognize what you are investing in when you choose a Goodyear welted boot or shoe. It’s a decision based on prioritizing specific, time-tested qualities.

- If your primary focus is longevity and repairability: Goodyear welt is the definitive choice, as it is engineered specifically to be resoled multiple times, drastically extending its usable life.

- If your primary focus is stability and protection: The robust, dual-stitch construction provides a stable platform and superior water resistance for demanding use.

- If your primary focus is long-term value: While the upfront cost is higher, the ability to repair the footwear for a fraction of the original price makes it a more economical choice over many years.

By choosing a Goodyear welted product, you are opting into a manufacturing legacy that values craftsmanship, durability, and sustainability over disposability.

Summary Table:

| Era | Key Development | Impact |

|---|---|---|

| Pre-1870s | Entirely hand-sewn welt construction | Slow, expensive luxury item |

| 1870s | Charles Goodyear Jr.'s patented machinery | Scalable production of durable footwear |

| Mid-20th Century | Rise of cheaper construction methods | Decline in use; shift to disposable footwear |

| Modern Day | Resurgence as a mark of quality | Recognized for durability, repairability, and long-term value |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including time-tested constructions like the Goodyear welt, ensuring superior durability and value for your customers.

Ready to offer your customers footwear built to last? Contact our team today to discuss your manufacturing needs and how we can help you deliver exceptional quality.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do Deep Learning Neural Networks contribute to safety behavior analysis? Unlocking High-Accuracy Behavioral Insights

- How does the adjustment of the inner pressure of air-cushioned insoles affect the risk of plantar skin damage? Minimize Ulcers & Enhance Foot Health

- How do pressure sensor systems validate diabetic shoe lasts? Ensure Safety with Quantitative Precision

- How should horse boots be cleaned and stored? Protect Your Investment with a Simple Care Routine

- What factors should be considered when buying new lace-up boots? Find Your Perfect Fit & Purpose

- What alternative to snake boots can provide protection against snake bites? Use Snake Gaiters for Versatile Defense.

- How does an industrial-grade laboratory hydraulic press assist in footwear fabric characterization? Ensure Data Accuracy

- How are optical motion capture and force plates used to validate wearable insoles? Ensure Gold-Standard Accuracy.