To ensure a comfortable fit, you must test boots in conditions that mimic your workday. This means trying them on in the late afternoon when your feet are naturally swollen, wearing the exact type of thick socks you use on the job, and ensuring there is a snug fit in the heel with ample room for your toes to move.

The challenge isn't just finding a comfortable boot; it's finding one that remains comfortable and supportive for 12-hour shifts while meeting the absolute, non-negotiable safety standards of the oilfield.

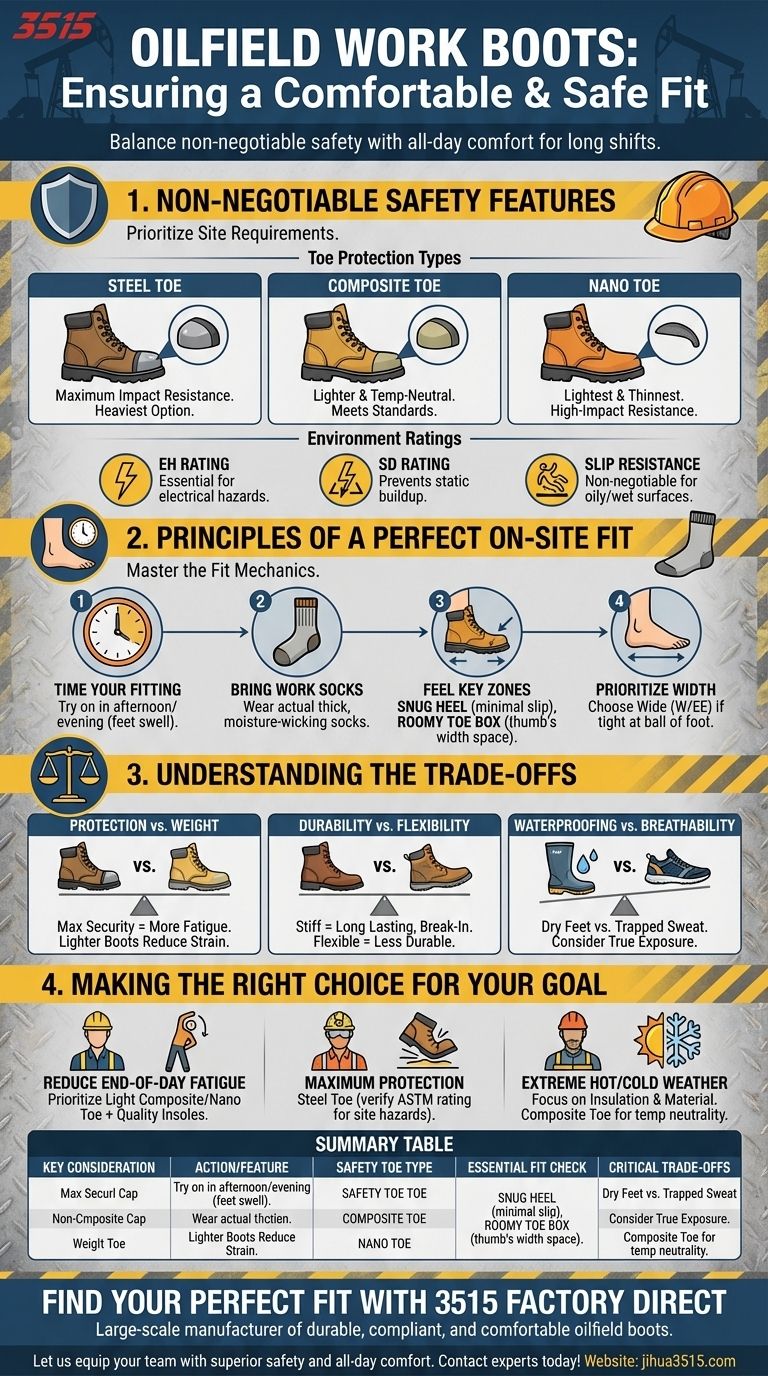

First, Verify the Non-Negotiable Safety Features

Before you can even consider comfort, your boots must meet the specific Personal Protective Equipment (PPE) requirements for your site. An uncomfortable boot is a problem; an unsafe boot is a catastrophic liability.

Understand Required Toe Protection

Your first check is the safety toe. The choice impacts weight, which is a key factor in long-term comfort.

- Steel Toe: The traditional standard for maximum impact resistance. It is often the heaviest option.

- Composite Toe: Lighter than steel and doesn't conduct cold or heat, which is a major comfort factor in extreme temperatures. They meet the same ASTM safety standards.

- Nano Toe: The most lightweight and thinnest option, offering high-impact resistance without the bulk.

Match the Rating to Your Environment

Beyond the toe, your boot must have the correct electrical and slip-resistance ratings for your specific role.

- Electrical Hazard (EH): Essential if you work near live conductors or wiring.

- Static Discharge (SD): Necessary in environments where static buildup could ignite flammable materials.

- Slip Resistance: A non-negotiable feature for surfaces slick with oil, mud, or water. Check for a high-traction outsole design.

The Principles of a Perfect On-Site Fit

Once you have a selection of compliant boots, you can focus entirely on the mechanics of the fit. This is a hands-on process that requires attention to detail.

Time Your Fitting Correctly

Your feet swell throughout the day from heat and standing. Always shop for and try on work boots in the afternoon or early evening to get the most accurate measurement.

Bring Your Work Socks

Never try on work boots with thin athletic or dress socks. Bring a pair of the cushioned, moisture-wicking socks you actually wear on the rig to assess the true volume and fit.

Feel for the Key Fit Zones

When you put the boot on, stand up and pay attention to two critical areas.

- The Heel: Your heel should feel "locked in" with minimal to no slipping as you walk. A little initial slip is normal in stiff leather boots, but it shouldn't be excessive.

- The Toe Box: You should have about a half-inch of space (roughly a thumb's width) between your longest toe and the end of the boot. Your toes must have room to wiggle and splay out freely.

Prioritize Width, Not Just Length

Many fit problems come from boots that are too narrow, not too short. If a boot feels tight across the ball of your foot, ask for a wide (W or EE) version instead of going up a half-size.

Understanding the Inevitable Trade-offs

Every work boot is a balance of competing features. Understanding these compromises helps you select the right boot for your specific needs and avoid common pitfalls.

Protection vs. Weight

A heavier boot with more protective features, like a steel toe and a thick puncture-resistant sole, offers maximum security. However, that extra weight causes significant fatigue over a long shift. Lighter composite-toe boots can dramatically reduce leg strain.

Durability vs. Flexibility

The most durable boots are often made of thick, stiff leather. While they will last longer, they require a significant "break-in" period that can be uncomfortable. A more flexible boot may feel better out of the box but may not withstand the same level of abuse.

Waterproofing vs. Breathability

A fully waterproof membrane is essential for keeping your feet dry in wet conditions. However, this same barrier can trap sweat, leading to moisture buildup and discomfort inside the boot. Consider how much true water exposure you face versus the need for your feet to breathe in hot weather.

Making the Right Choice for Your Goal

Use your primary daily challenge to guide your final selection.

- If your primary focus is reducing end-of-day fatigue: Prioritize a lightweight composite or nano-toe boot and be willing to invest in high-quality, supportive insoles.

- If your primary focus is maximum protection from crush injuries: A steel-toe boot remains the gold standard, but verify the specific ASTM rating is appropriate for your site's hazards.

- If your primary focus is working in extreme hot or cold weather: Pay close attention to insulation and the boot's material, as a composite toe will not transfer temperature like a steel toe will.

Ultimately, the right boot is the one that allows you to forget you are wearing it while keeping you safe on the job.

Summary Table:

| Key Consideration | Action/Feature |

|---|---|

| Safety Toe Type | Steel (heavy), Composite (light/temp-neutral), Nano (lightest) |

| Proper Fit Timing | Try on boots in the afternoon when feet are naturally swollen. |

| Essential Fit Check | Snug heel, thumb's width of space in toe box, correct width. |

| Critical Trade-offs | Protection vs. Weight, Durability vs. Flexibility, Waterproofing vs. Breathability |

Find Your Perfect Fit with 3515 Factory Direct

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oilfield boots and work shoes, ensuring you get durable, compliant, and comfortable footwear tailored to your exact needs.

Let us help you equip your team with boots that combine superior safety with all-day comfort.

Contact our experts today for a quote and to discuss your requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How should Western work boots be properly cared for? A 4-Step Guide to Lasting Durability

- What safety standards do composite toe work boots typically meet? Essential ASTM F2413 Guide

- What are some key differences between traditional and modern engineer boots? Choose the Right Style for Your Needs

- What are the compression standards for Class C/75 work boots? Meet the 2,500-Pound Safety Requirement

- What role do cushioned insoles play in PVC work boots? Boost Comfort and Reduce Fatigue

- What materials are used in composite toe work boots, and what are their advantages? Get Lightweight, Non-Conductive Safety

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection

- In what work environments are soft-toe boots recommended? Ideal for Low-Risk Jobs Needing All-Day Comfort