To effectively promote workplace safety and compliance, employers must implement a system of clear environmental controls, documented policies, and consistent enforcement. This includes identifying areas requiring Personal Protective Equipment (PPE), using clear and visible signage, and ensuring all personnel use appropriate gear like protective footwear to mitigate known hazards.

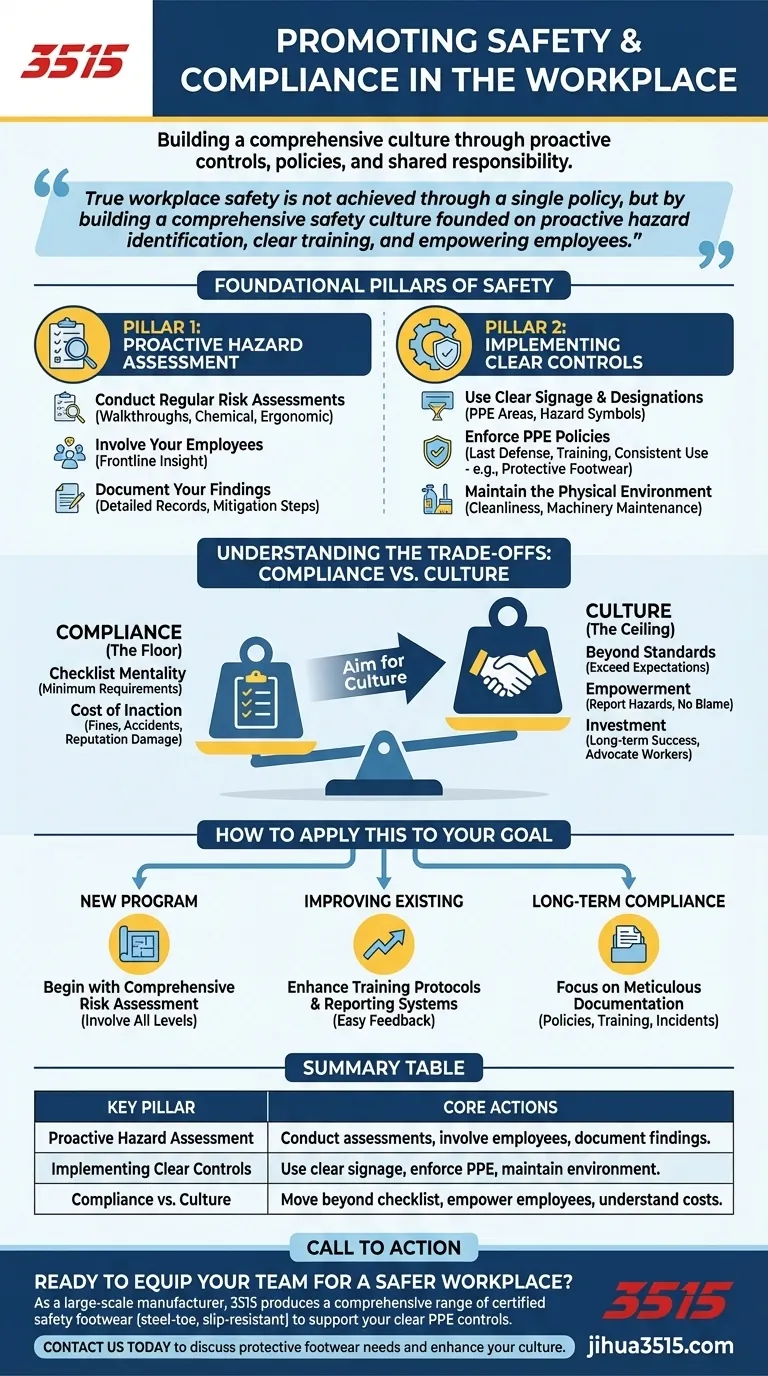

True workplace safety is not achieved through a single policy, but by building a comprehensive safety culture. This culture is founded on proactive hazard identification, clear and consistent training, and empowering employees to be active participants in their own safety.

Foundational Pillar 1: Proactive Hazard Assessment

Before you can enforce rules, you must first understand the risks. A thorough and ongoing assessment of your workplace is the bedrock of any effective safety program.

Conduct Regular Risk Assessments

A formal risk assessment involves systematically walking through the workplace to identify potential hazards. This includes everything from slip-and-fall risks and chemical exposure to ergonomic strains and machinery dangers.

Involve Your Employees

Your frontline workers have the most direct and consistent exposure to potential hazards. Involving them in the assessment process provides invaluable insight that management might overlook.

Document Your Findings

Maintaining a detailed record of identified hazards, the potential harm they could cause, and the steps taken to mitigate them is critical for both continuous improvement and legal compliance.

Foundational Pillar 2: Implementing Clear Controls

Once you understand the risks, you can implement controls to eliminate or reduce them. This is where policies and physical changes to the work environment come into play.

Use Clear Signage and Designations

Clearly mark areas that require specific PPE, such as hard hats, safety glasses, or high-visibility vests. Use universally understood symbols for hazards like wet floors, high voltage, or forklift traffic.

Enforce Personal Protective Equipment (PPE) Policies

PPE should be considered the last line of defense after other controls have been put in place. Ensure that not only is the correct PPE provided, but that employees are trained on how to use it correctly and that its use is consistently enforced.

Maintain the Physical Environment

A clean and well-maintained workplace is inherently safer. Regular housekeeping prevents clutter that can cause trips and falls, and a strict maintenance schedule for all machinery prevents dangerous equipment failures.

Understanding the Trade-offs: Compliance vs. Culture

Simply meeting the minimum legal requirements is not the same as creating a genuinely safe workplace. Understanding this distinction is key to long-term success.

The Pitfall of a "Checklist" Mentality

Compliance is the floor, not the ceiling. A business that only does the bare minimum required by law is often one incident away from disaster. A strong safety culture aims to exceed standards, not just meet them.

The Cost of Inaction

Investing in a robust safety program is not an expense; it is a critical investment. The costs of an accident—including fines, legal fees, lost productivity, and reputational damage—far outweigh the cost of prevention.

Balancing Enforcement with Empowerment

While strict enforcement is necessary, the most effective safety programs empower employees to report near-misses and potential hazards without fear of blame. This turns every worker into a safety advocate.

How to Apply This to Your Goal

Your immediate actions should be guided by your primary objective.

- If your primary focus is establishing a new safety program: Begin with a comprehensive risk assessment that involves employees from every level of the organization.

- If your primary focus is improving an existing program: Concentrate on enhancing your training protocols and creating a system for employees to easily report hazards and provide feedback.

- If your primary focus is ensuring long-term compliance: Focus on meticulous documentation of all policies, training sessions, inspections, and incidents to create a clear and defensible record.

Ultimately, creating a safe and compliant workplace is a continuous process built on the principle of shared responsibility.

Summary Table:

| Key Pillar | Core Actions |

|---|---|

| Proactive Hazard Assessment | Conduct regular risk assessments, involve employees, and document findings. |

| Implementing Clear Controls | Use clear signage, enforce PPE policies, and maintain the physical environment. |

| Compliance vs. Culture | Move beyond a checklist mentality by empowering employees and understanding the cost of inaction. |

Ready to equip your team for a safer workplace?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. From steel-toe boots to slip-resistant shoes, our products are designed to meet the highest safety standards, supporting the clear PPE controls your safety program requires.

Contact us today to discuss your protective footwear needs and enhance your workplace safety culture.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why is Ethylene-Vinyl Acetate (EVA) a primary choice for shoe midsoles? Optimize Comfort and Joint Protection

- Why is a full-wrap seamless structure essential in medical footwear? Ultimate Safety and Sterility for Healthcare

- What are some additional tips for caring for cowboy boots? Essential Habits for Long-Lasting Boots

- What are the differences between field boots and dress boots? A Guide to Equestrian Performance Footwear

- What is the purpose of using an industrial-grade weighted backpack? Ensure Experimental Accuracy & Load Stability

- What are the characteristics of knit as a shoe material? Discover Unmatched Comfort & Breathability

- What are the rider's preferences for the new boots? Find the Perfect Balance of Protection, Durability & Value

- How does an automated sliding control system ensure reliability in footwear & turf friction experiments? Achieve precise, reproducible data.