In this specific footwear, the soles are attached to the main body of the shoe using a time-tested process known as cemented construction. A natural rubber-based glue is gently heated to activate its adhesive properties and then applied to bond the pre-shaped upper part of the shoe directly to the sole.

This method, known as cemented construction, creates a lightweight and flexible shoe by relying on a strong adhesive bond. While effective, it represents one of several fundamental approaches to shoemaking, each with distinct implications for durability, comfort, and repairability.

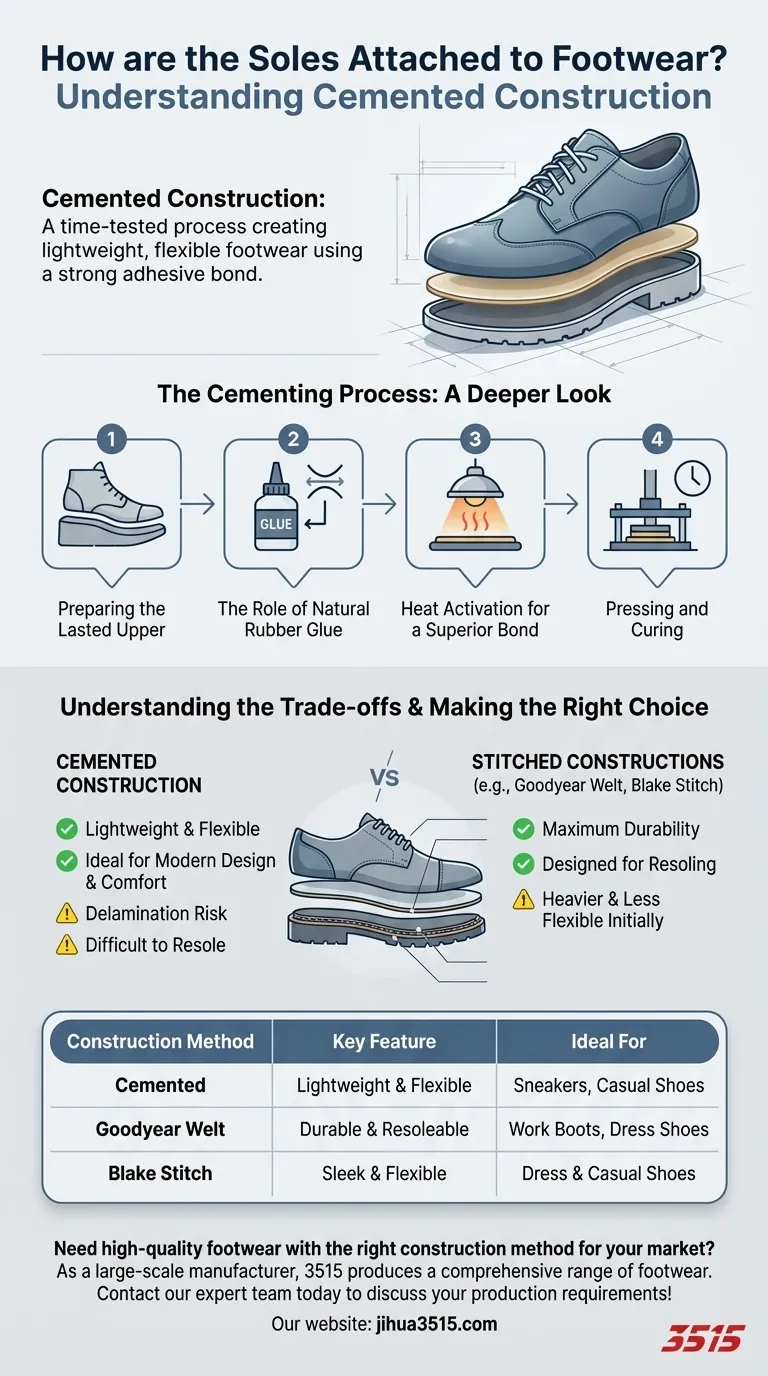

The Cementing Process: A Deeper Look

Understanding how a sole is attached is crucial to understanding the shoe's overall performance and lifespan. The cemented method described is a precise process involving several key stages.

Preparing the "Lasted Upper"

Before the sole can be attached, the top part of the shoe (the upper) is stretched and shaped over a mold called a last. This gives the shoe its final form. The bottom edge of this lasted upper is then prepared to create a clean surface for the adhesive.

The Role of Natural Rubber Glue

Natural rubber glue is chosen for its strong, flexible bond. Unlike rigid epoxies, it allows the sole to flex naturally with the foot during movement, which is essential for comfort.

Heat Activation for a Superior Bond

The glue is gently heated just before application. This step is critical as it lowers the viscosity of the adhesive, allowing it to spread evenly and penetrate the materials more effectively. It activates the chemical components to ensure the strongest possible bond once cooled.

Pressing and Curing

Once the heated glue is applied, the sole and the upper are joined together in a high-pressure press. This pressure ensures there are no air gaps and that the two components make full contact. The shoe is then left to cure, allowing the adhesive to set completely and form a permanent, solid bind.

Understanding the Trade-offs

No single construction method is universally superior; each involves trade-offs. Choosing the right shoe means understanding these differences.

Durability and Delamination Risk

While a well-executed cemented bond is strong for everyday wear, it can be susceptible to breaking down over time, especially with exposure to excessive moisture or heat. This is known as delamination, where the sole begins to peel away from the upper. Stitched constructions, like a Goodyear welt, offer greater long-term durability in this regard.

The Challenge of Resoling

Cemented construction makes resoling difficult. Removing the old sole often damages the upper, and it's challenging to create a new bond that is as strong as the original factory seal. In contrast, shoes made with a stitched welt are designed specifically to be resoled multiple times, significantly extending their lifespan.

Benefits in Flexibility and Weight

The primary advantage of cementing is the creation of a lightweight and highly flexible shoe. With no extra layers of stitching or welting material, the shoe can move more freely with the foot. This method is ideal for athletic footwear, sneakers, and many casual shoes where comfort and low weight are paramount.

Making the Right Choice for Your Goal

Understanding sole attachment helps you select footwear that aligns with your specific needs for longevity, comfort, and value.

- If your primary focus is lightweight comfort and modern design: Footwear with cemented construction is an excellent and highly popular choice.

- If your primary focus is maximum durability and the ability to repair: Seek out footwear with a stitched construction, such as a Goodyear welt or Blake stitch.

Ultimately, knowing how a shoe is built empowers you to invest in the quality and performance that truly matter to you.

Summary Table:

| Construction Method | Key Feature | Ideal For |

|---|---|---|

| Cemented | Lightweight & Flexible | Sneakers, Casual Shoes |

| Goodyear Welt | Durable & Resoleable | Work Boots, Dress Shoes |

| Blake Stitch | Sleek & Flexible | Dress & Casual Shoes |

Need high-quality footwear with the right construction method for your market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable stitched welts and lightweight cemented constructions. We can help you select the perfect build for your customers' needs, ensuring quality, comfort, and value.

Contact our expert team today to discuss your footwear production requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What is the role of silicone-based release agents in EVA shoe sole production? Master the Demolding Process

- How do winter boots compare in warmth to regular shoes with overshoes? The Ultimate Guide to Cold-Weather Footwear

- How does a multi-camera motion capture system validate gait and posture? The Science of Foot Strike Correlations

- Which option is better for occasional winter riders? Choose Overshoes for Maximum Value & Convenience

- How does water utilization efficiency impact footwear manufacturing sustainability? Optimize Your Industrial Design

- How can one maintain the waterproofing of leather boots? A 3-Step Guide to Lasting Protection

- Why is sole wear an important indicator of boot condition? The Critical Link to Safety & Performance

- Why is closed-cell cross-linked polyethylene foam the benchmark in orthotics? Achieve Data-Driven Validation