The manufacturing of PVC work boots is centered around a highly efficient process called injection molding. A specialized compound of Polyvinyl Chloride (PVC) is heated until molten and then injected under high pressure into a boot-shaped mold, where it cools and solidifies into a seamless, single-piece final product.

The core principle to understand is that the injection molding process is what gives PVC boots their key advantages—seamless waterproofing and affordability—but also defines their limitations compared to boots made from other materials like rubber or leather.

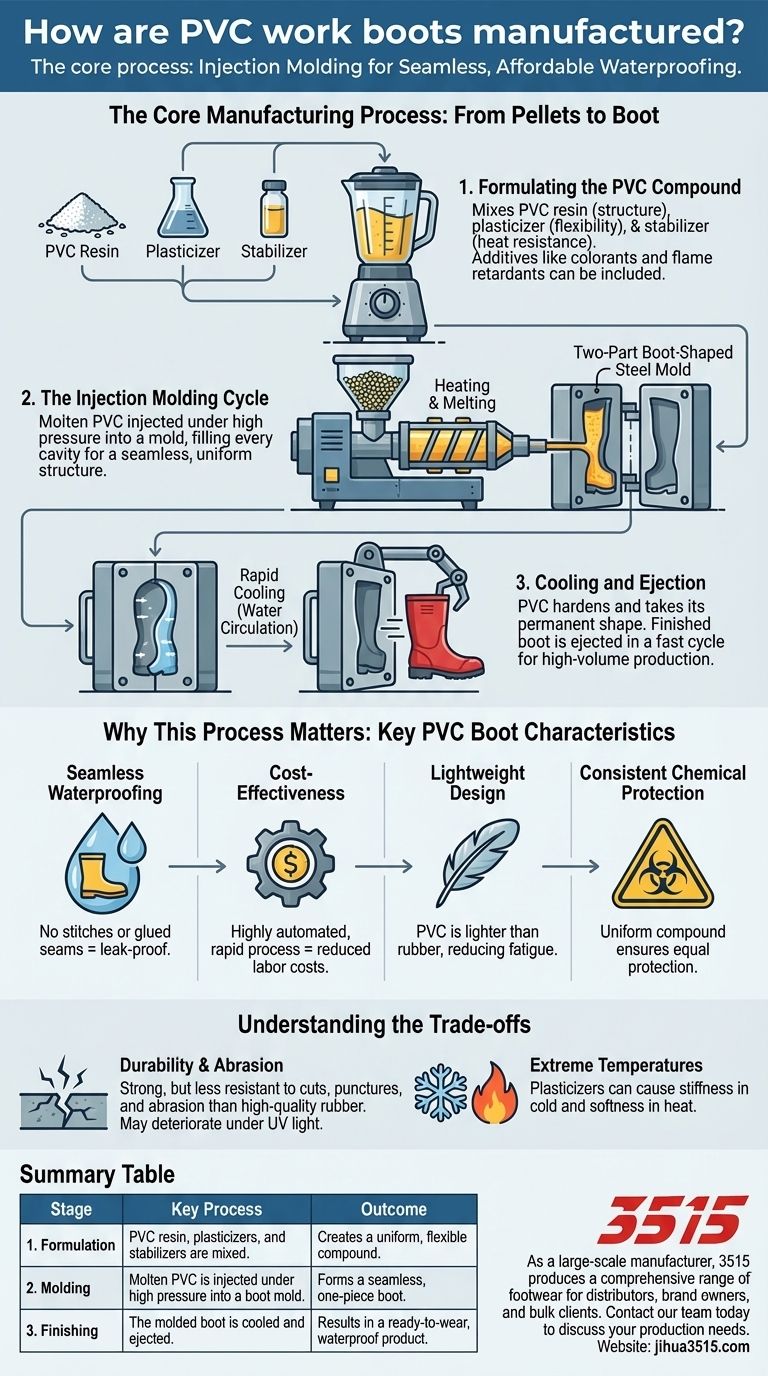

The Core Manufacturing Process: From Pellets to Boot

The creation of a PVC work boot is a precise, automated cycle designed for high-volume production. It transforms raw materials into a finished, functional piece of protective footwear in just a few steps.

Step 1: Formulating the PVC Compound

Before molding, the raw materials are carefully mixed. The primary ingredient is PVC resin, which provides the boot's fundamental structure and chemical resistance.

To this, a plasticizer is added to increase softness and flexibility, making the boot comfortable. A stabilizer is also crucial, preventing the PVC from decomposing under the intense heat of the molding process.

Other additives like colorants, flame retardants, or fillers can be included to meet specific performance requirements for different jobs.

Step 2: The Injection Molding Cycle

The prepared PVC compound, typically in pellet form, is fed into an injection molding machine. Here, it is heated and melted into a liquid state.

This molten PVC is then injected with extreme force into a two-part, boot-shaped steel mold. The pressure ensures the material fills every cavity, creating a uniform and complete boot structure without any seams.

Step 3: Cooling and Ejection

Once the mold is filled, it is cooled rapidly, usually with circulating water. This causes the PVC to harden and take its permanent shape.

The mold then opens, and the finished boot is ejected. This cycle is very fast, allowing for the efficient production of thousands of boots per day.

Why This Process Matters: Key PVC Boot Characteristics

The injection molding method is not just a manufacturing detail; it directly defines the performance, benefits, and purpose of the final product.

Seamless Waterproofing

Because the boot is created as a single, continuous piece, there are no stitches or glued seams that can fail and allow water to leak in. This makes injection-molded PVC boots exceptionally waterproof.

Cost-Effectiveness

Injection molding is a highly automated and rapid process. This efficiency significantly reduces labor costs and production time, which is why PVC boots are generally more affordable than boots made from vulcanized rubber or leather.

Lightweight Design

PVC as a material is inherently lighter than traditional dense rubber. This, combined with the efficient molding process, results in a boot that reduces fatigue for workers who are on their feet for long hours.

Consistent Chemical Protection

The uniform mixture of the PVC compound ensures that every part of the boot offers the same level of protection against chemicals, acids, and bases. There are no weak points in its chemical barrier.

Understanding the Trade-offs

While the manufacturing process provides significant benefits, it also creates important trade-offs that you must consider.

Durability and Abrasion

While strong, PVC can be less resistant to cuts, punctures, and heavy abrasion compared to high-quality vulcanized rubber. The material may also deteriorate faster when exposed to certain chemicals or constant UV light.

Performance in Extreme Temperatures

The plasticizers that make PVC flexible can cause the material to become stiff and rigid in very cold weather. Conversely, in extreme heat, the material can become overly soft.

Making the Right Choice for Your Goal

Selecting the right boot depends entirely on the demands of your environment and the priorities of your work.

- If your primary focus is cost-effective, reliable waterproofing for wet conditions: PVC's seamless, injection-molded construction is the ideal choice.

- If your primary focus is durability in rugged, abrasive environments or extreme cold: You may need to consider boots made from specialized rubber compounds.

- If your primary focus is reducing fatigue and maximizing comfort during long shifts: The lightweight nature of PVC provides a significant advantage over heavier materials.

By understanding how a PVC boot is made, you can better appreciate its inherent strengths and make an informed decision for your specific needs.

Summary Table:

| Stage | Key Process | Outcome |

|---|---|---|

| 1. Formulation | PVC resin, plasticizers, and stabilizers are mixed. | Creates a uniform, flexible compound. |

| 2. Molding | Molten PVC is injected under high pressure into a boot mold. | Forms a seamless, one-piece boot. |

| 3. Finishing | The molded boot is cooled and ejected. | Results in a ready-to-wear, waterproof product. |

Need reliable, high-volume PVC work boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get durable, cost-effective safety footwear tailored to your market's demands.

Contact our team today to discuss your production needs and get a competitive quote.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do wedge sole work boots prevent slips and falls? Maximize Grip on Concrete & Hard Floors

- How can heavy duty boots be weatherproofed? A Step-by-Step Guide to Lasting Protection

- What are packer boots designed for? A Hybrid Boot for Riding and Rugged Terrain Work

- What material is recommended for workers needing long-term wear, especially those with plantar fasciitis or diabetes? PU for Superior Comfort

- Why is it not advisable to store work boots for long periods? Prevent PU Sole Failure

- What are some common styles of work boots? Find the Perfect Fit for Your Job

- What are moc toe work boots designed for? Superior Comfort and Mobility for Tradespeople

- What is the most important factor to consider when purchasing new work boots? Align Safety with Your Job's Demands