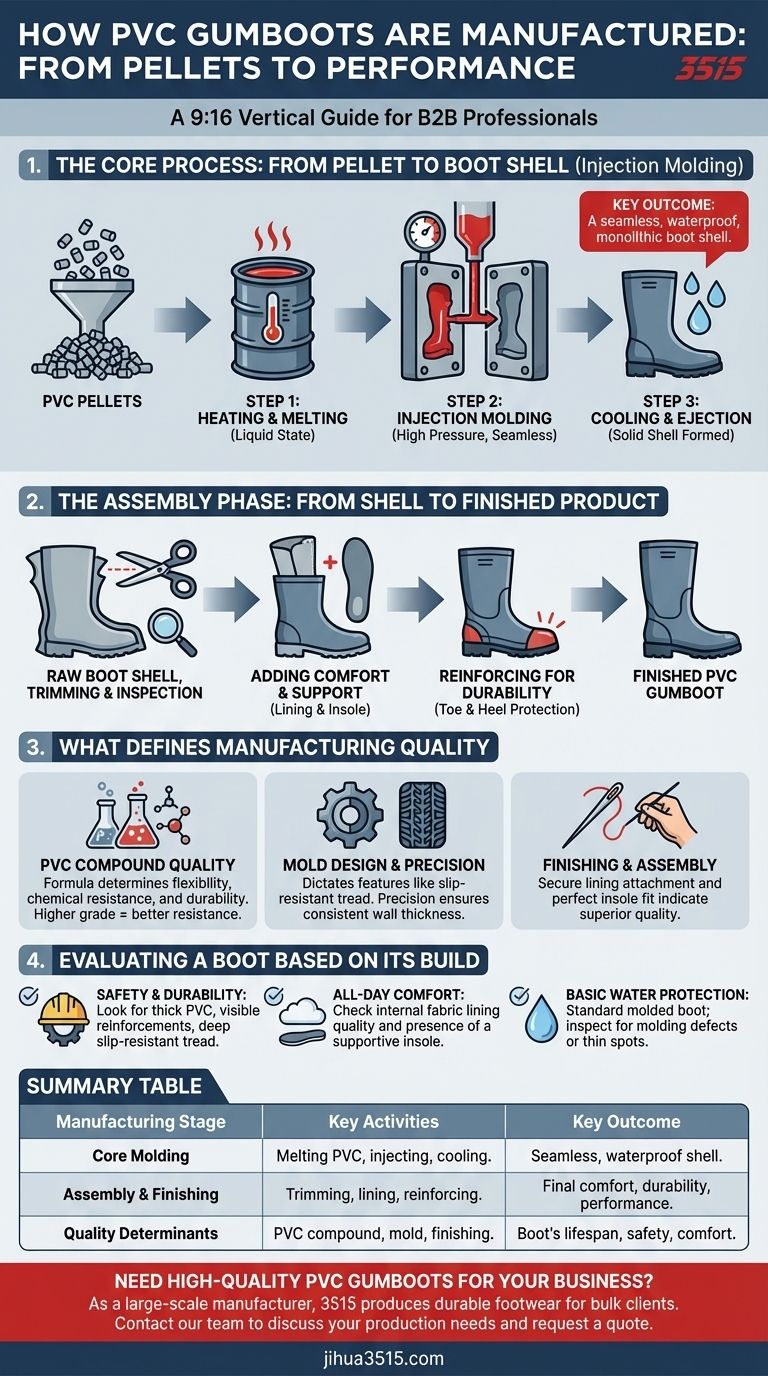

In essence, PVC gumboots are manufactured using a process called injection molding. This industrial technique involves melting raw Polyvinyl Chloride (PVC) pellets into a liquid, which is then injected under high pressure into a precise, boot-shaped mold. The material is then cooled to form a solid, seamless, and waterproof boot shell.

The creation of a PVC gumboot is a two-part story: a highly automated molding process creates the core waterproof structure, while the subsequent finishing and assembly steps determine the boot's final comfort, durability, and performance characteristics.

The Core Process: From Pellet to Boot Shell

The initial phase of manufacturing is focused on forming the main body of the gumboot. This stage is highly automated and prized for its speed and consistency.

Step 1: Preparing the Raw Material

The process begins with small, solid cylinders of raw material known as PVC pellets.

These pellets are heated to a precise temperature until they melt into a consistent, liquid-like state, ready for molding.

Step 2: The Injection Molding Cycle

The molten PVC is then forced into a locked, two-part steel mold shaped like a boot. This injection happens under immense pressure to ensure the material fills every detail of the mold cavity.

The primary advantage of this method is the creation of a single, monolithic boot shell with no seams, which is the key to its waterproof design.

Step 3: Cooling and Ejection

Once injected, the mold is rapidly cooled, which causes the liquid PVC to solidify into its final, durable form.

After a short cooling period, the mold opens, and the newly formed boot shell is ejected, ready for the next stage.

From Shell to Finished Product: The Assembly Phase

A raw boot shell is functional but incomplete. The assembly phase transforms this basic shell into a finished product ready for use, combining both automated and manual techniques.

Trimming and Inspection

First, any excess material left over from the molding process, known as "flash," is carefully trimmed from the boot.

Each shell then undergoes a quality control inspection to ensure it is free from structural defects, weak spots, or imperfections.

Adding Comfort and Support

This is where features that directly impact the wearer's experience are added.

A soft fabric lining is often inserted to improve comfort and help manage moisture. A cushioned insole is placed inside to provide support.

Reinforcing for Durability

For work and safety boots, critical areas are often reinforced.

Components like strengthening bands or extra layers of material may be added to high-wear areas. This is also the stage where features like reinforced toes and heels are finalized.

What Defines Manufacturing Quality

Not all PVC gumboots are created equal. The subtle differences in the manufacturing process have a significant impact on the final product's performance and lifespan.

The Quality of the PVC Compound

The specific formula of the PVC pellets matters immensely. Different compounds offer varying levels of flexibility, chemical resistance, and durability. A higher-grade compound results in a boot that resists cracking and stands up to harsh conditions.

Mold Design and Precision

The quality of the steel mold dictates the final product's features. A precision-engineered mold is required to create a deep, effective, slip-resistant sole tread. Poor mold design can result in inconsistent wall thickness, creating potential weak points.

The Importance of Finishing

How well the final components are assembled is a clear indicator of quality. In a superior boot, the lining is securely attached without bunching, and the insole fits perfectly. Poor finishing can lead to premature failure and significant discomfort.

Evaluating a Boot Based on Its Build

By understanding the manufacturing process, you can make a more informed choice based on your specific needs.

- If your primary focus is safety and durability: Look for thick PVC material, visible reinforcement at the toe and heel, and a deep, well-defined slip-resistant tread.

- If your primary focus is all-day comfort: Pay close attention to the quality of the internal fabric lining and the presence of a supportive, well-fitted insole.

- If your primary focus is basic water protection: A standard, single-piece molded boot will be effective, but always inspect it for any obvious molding defects or thin spots in the material.

Ultimately, recognizing the signs of a well-executed manufacturing process allows you to choose a gumboot that is truly built for its purpose.

Summary Table:

| Manufacturing Stage | Key Activities | Key Outcome |

|---|---|---|

| Core Molding | Melting PVC pellets, injecting into a boot mold, cooling. | Creates a seamless, waterproof boot shell. |

| Assembly & Finishing | Trimming, adding lining and insole, reinforcing high-wear areas. | Determines final comfort, durability, and performance. |

| Quality Determinants | PVC compound quality, mold precision, assembly finishing. | Defines the boot's lifespan, safety, and comfort. |

Need high-quality PVC gumboots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable footwear for distributors, brand owners, and bulk clients. Our advanced injection molding capabilities ensure seamless, waterproof boots built to your exact specifications, from safety-focused industrial designs to comfortable everyday wear.

Contact our team today to discuss your production needs and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are duck boots? The Ultimate Hybrid Footwear for Wet Conditions

- What are the benefits of the waterproof feature in PVC boots? Keep Feet Dry & Protected in Any Condition

- How does neoprene enhance the performance of Wellington boots? Superior Warmth & Comfort in Cold Conditions

- Why are wellington boots particularly suitable for children? Unlock All-Weather Play & Development

- What materials are Wellington boots typically made from? Natural Rubber, PVC, or Neoprene?

- Why is PVC resin important in making rain boots? The Key to Durability & Performance

- What are the benefits of PVC boots for gardening? Waterproof & Affordable Protection

- What are the advantages of rubber boots for deer hunting in terms of scent control? Master Stealth with Scent-Proof Footwear